Modified nano titanium dioxide and calcium-magnesium-zinc composite stabilizer for microwave-assisted synthesis of PVC and application thereof

A technology of nano-titanium dioxide and composite stabilizer, applied in the field of polymer material processing aids, can solve the problems of high price of methyl tin mercaptide, poor heat resistance, etc., achieve excellent thermal stabilization effect, improve heat resistance, promote light Degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Take 1.820 g TiO 2 Nanoparticles added to deionized water, formulated as 5% TiO 2 Aqueous solution, stirring for 30 minutes, then taking 0.180 g of folic acid and adding deionized water to prepare 0.5% FA aqueous solution, stirring and dissolving for 30 minutes to obtain a uniform solution. Then add the folic acid solution to the titanium dioxide suspension, and stir for 60 minutes so that FA is grafted onto the surface of nano-titanium dioxide particles, filter, wash, and vacuum-dry. powder product.

Embodiment 2

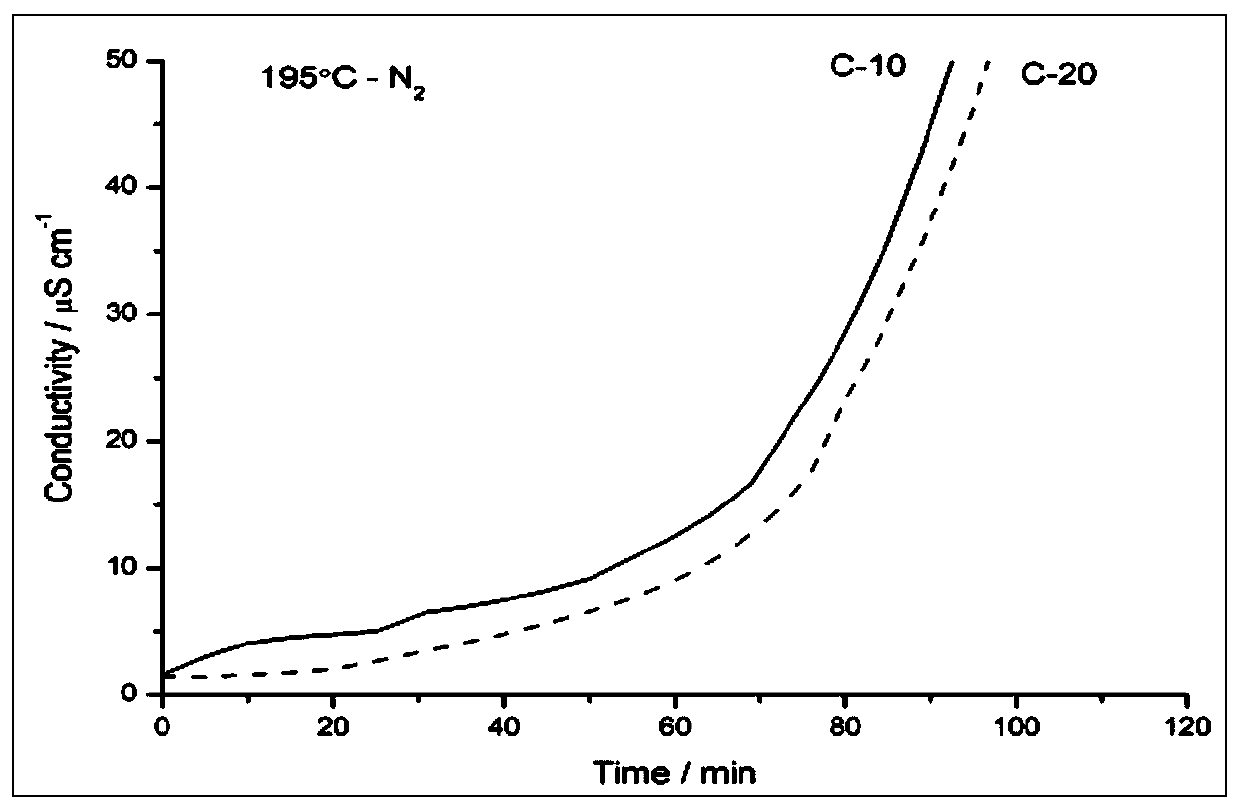

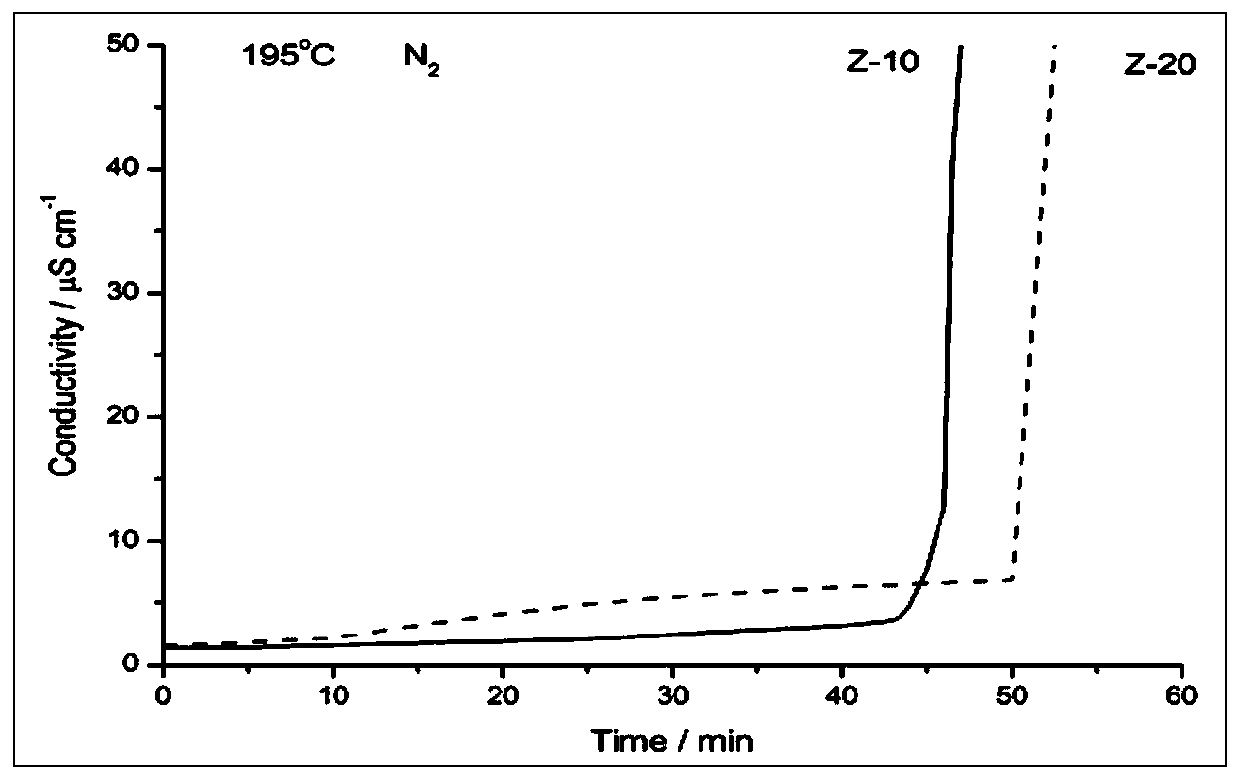

[0052] Get 100 parts of PVC, 50 parts of DOTP, adopt the folic acid modified TiO prepared in the embodiment 1 of microwave heating 2 Mix and dissolve 3 parts of nanoparticles (FA content 9%), 5 parts of calcium metal soap, and 0.5 part of organotin stabilizer, and forcefully stir at 40° C. for 1 hour to obtain a uniform premix; Banbury in the mixer, melt temperature 170-175°C, banbury for 2-3min, wait for the shear force to drop first and then rise, after the end, use a flat vulcanizer to press to 1mm at 100°C to get PVC nanoparticle flakes C -20.

Embodiment 3

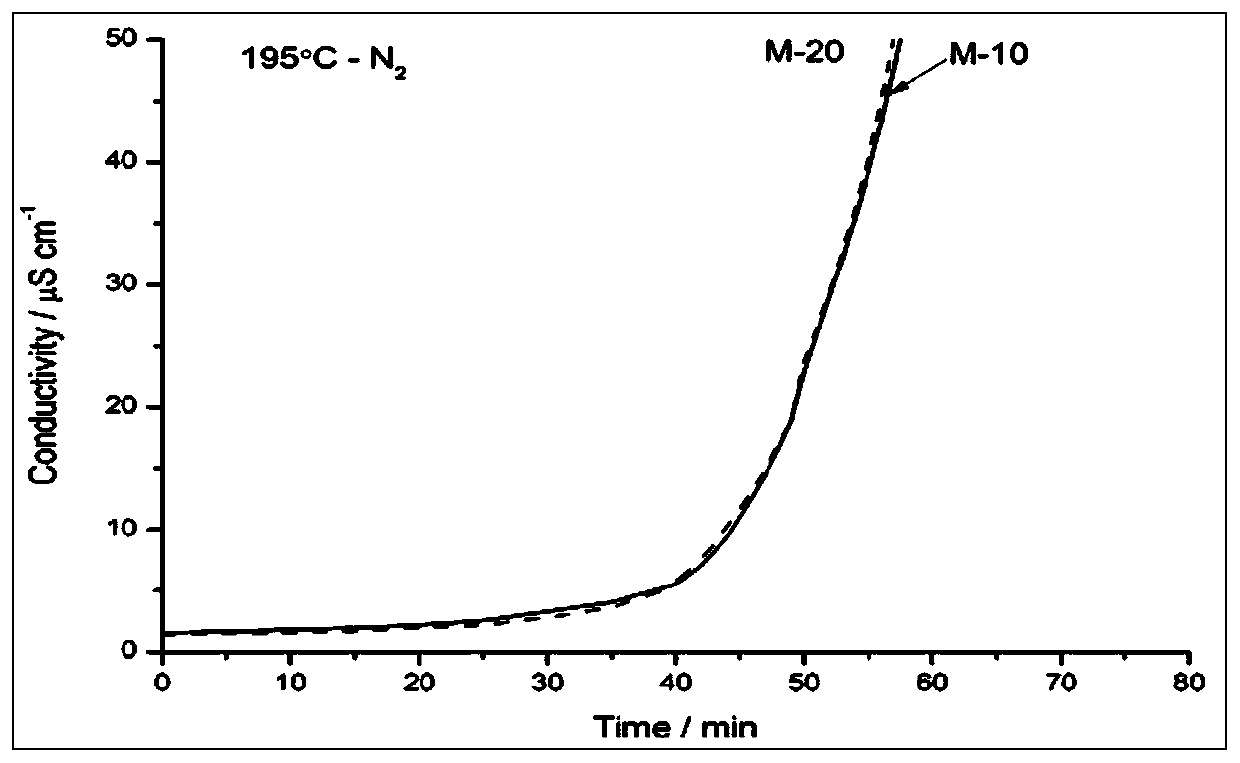

[0056] Using microwave heating, the folic acid modified TiO prepared in Example 1 2 3 parts of nanoparticle (FA content 9%) complex, magnesium metal soap (5 parts), and the rest are the same as in Example 2 to obtain PVC nanoparticle sheet M-20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com