Method for treating sludge by utilizing microbial flocculant and microbial wall breaking

A microbial flocculant and sludge treatment technology, applied in biological sludge treatment, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of ocean pollution, accumulation increase, air pollution, etc., and reduce investment costs , not easy to absorb, improve the effect of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

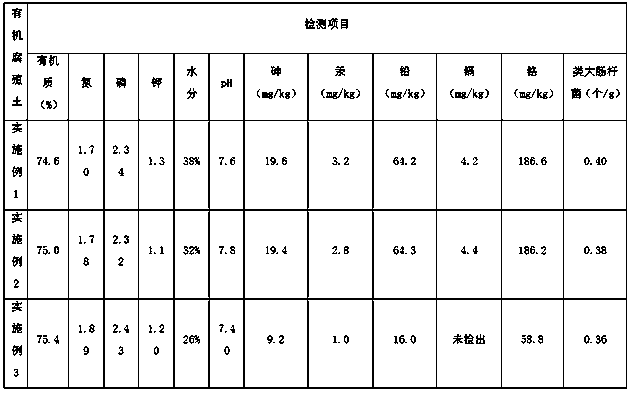

Embodiment 1

[0028] In this example, the sludge with a water content of 98% is treated and disposed of in Shou County Sewage Treatment Plant of Anhui Province (Shou County Qingyuan Water Co., Ltd.). The specific treatment and disposal method includes the following steps:

[0029] (1) Bio-modification of sludge: Desliming the remaining sludge with a moisture content of 98% is carried out by a desliming machine. During the desliming process, microbial flocculants are added, and the sludge and water are quickly separated by using the self-decomposed products of biological bacteria. To obtain modified sludge with a water content of 80%, add 2.3 kg of microbial flocculant for every 1 ton of modified sludge obtained; microbial flocculant includes protein, acidic polysaccharide, mucopolysaccharide, and aminopolysaccharide. Microbial flocculants can be decomposed and degraded in the natural environment, and the surface of the modified sludge particles loses chemical stability and coating properties...

Embodiment 2

[0033] In this example, the sludge with a water content of 98% is treated and disposed of in Shou County Sewage Treatment Plant of Anhui Province (Shou County Qingyuan Water Co., Ltd.). The specific treatment and disposal method includes the following steps:

[0034] (1) Bio-modification of sludge: Desliming the remaining sludge with a moisture content of 98% is carried out by a desliming machine. During the desliming process, microbial flocculants are added, and the sludge and water are quickly separated by using the self-decomposed products of biological bacteria. To obtain modified sludge with a water content of 80%, add 2.3 kg of microbial flocculant for every 1 ton of modified sludge obtained; microbial flocculant includes protein, acidic polysaccharide, mucopolysaccharide, and aminopolysaccharide. Microbial flocculants can be decomposed and degraded in the natural environment, and the surface of the modified sludge particles loses chemical stability and coating properties...

Embodiment 3

[0038] In this example, the sludge with a water content of 98% is treated and disposed of in Shou County Sewage Treatment Plant of Anhui Province (Shou County Qingyuan Water Co., Ltd.). The specific treatment and disposal method includes the following steps:

[0039] (1) Biomodification of sludge: The sludge with a water content of 98% is deslimed by a deslimer, and microbial flocculants are added during the desliming process, and the sludge and water are quickly separated by using the self-decomposed products of biological bacteria to obtain For the modified sludge with a moisture content of 70%, add 2.3kg of microbial flocculants for every 1 ton of modified sludge obtained; microbial flocculants include microbial flocculants including proteins, acidic polysaccharides, mucopolysaccharides, and aminopolysaccharides. Microbial flocculants can be decomposed and degraded in the natural environment, and the surface of the modified sludge particles loses chemical stability and coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com