Knife handle suitable for low-temperature minimal quantity lubrication

A technology of micro-lubrication and tool holders, which is applied in the direction of milling cutters, accessories of tool holders, clamping, etc., can solve the problems of heat insulation, insufficient sealing performance, external rotation and inner tool holders cannot be used in low-temperature micro-quantity lubrication cutting methods, etc., to achieve Overcoming ultra-low temperature medium seals, realizing green manufacturing, and improving cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions. In this embodiment, cryogenic nitrogen is used as the ultra-low temperature medium L1.

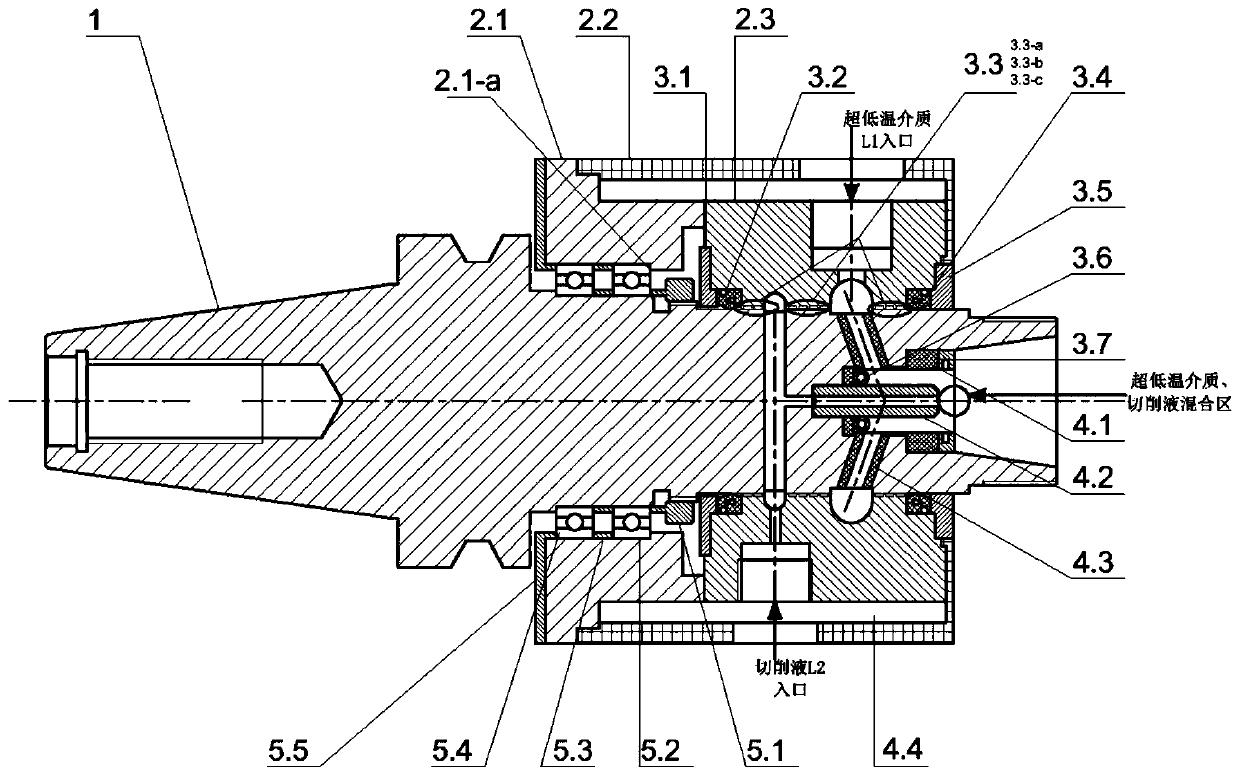

[0025] The tool holder suitable for low-temperature minimal quantity lubrication is improved on the basis of the traditional tool holder structure. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a tool holder suitable for low-temperature minimal quantity lubrication includes a tool holder main body, a peripheral static structure, a multi-layer sealing structure, a heat insulation structure, and a bearing support structure.

[0026] During installation, install the flow channel heat insulation sleeve 4.3 into the inner flow channel 1-a of the handle at low temperature, and cold install the heat insulation sleeve 4.1 of the handle main body according to the inner shaft shoulder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com