Double-body combined sealing strip for solid-shaped steel window

A combined sealing and solid belly technology, applied in sealing devices and other directions, can solve the problems of inability to apply and fail to reflect the beauty and simplicity of real web steel windows, and achieve the effects of simple and novel structure, long service life and improved use conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

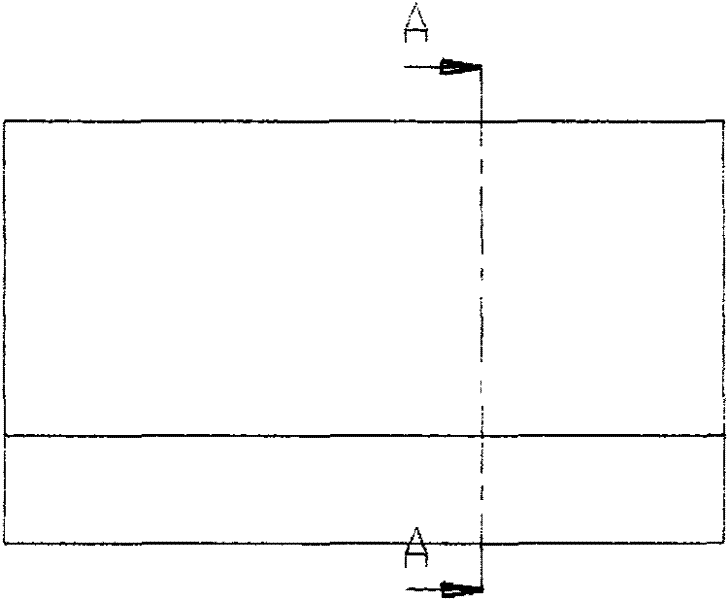

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] The example is a casement type solid web steel window with a casement type with top suspension, as shown in Figure 2. Wherein the casement sash (7) and the upper hanging casement sash (8) are movable parts, which can be opened and closed. After the sash is closed, the sash material (2) and the window frame material (1) are attached to each other, forming two bonding surfaces inside and outside. In order to make the two fit more closely, a two-body combined sealing strip is embedded in the groove of the sash material (2) and the window frame material (1) to increase the sealing performance.

[0018] The specific construction steps are: after selecting the material, first cut the soft body (4) and hard body (5) into long strips of the same size as the window sash and the window frame, and then insert the rubber strip boss of the soft body into the groove of the hard b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com