Preparation method of hydrophobic mineralized waste fiber adsorption material

A technology for waste fibers and adsorption materials, which is applied in the field of preparation of oil-absorbing materials, can solve the problems of high cost, low oil retention rate, complicated operation and the like, and achieves the effects of high oil retention rate, easy operation and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

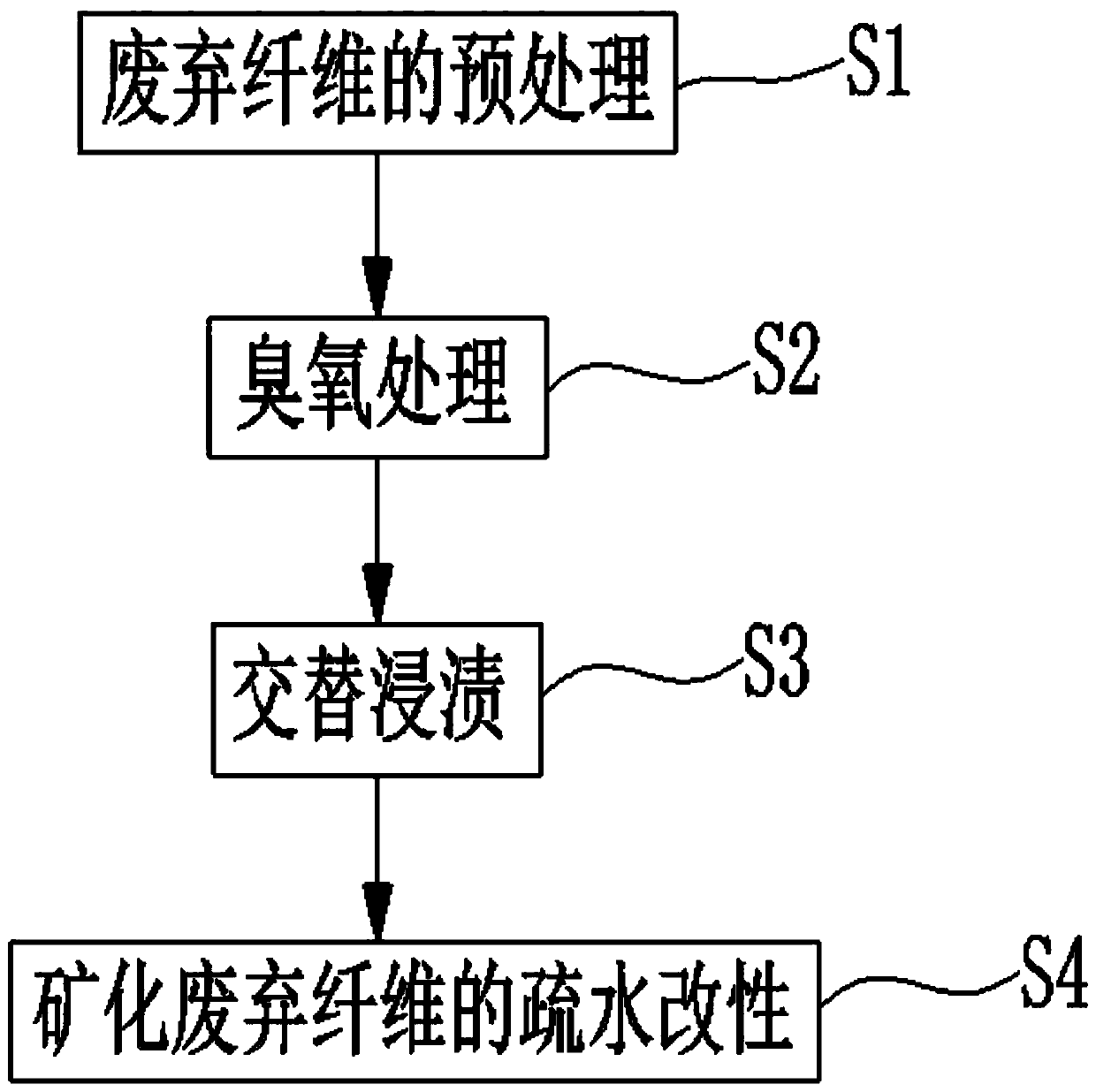

Method used

Image

Examples

Embodiment 1

[0036] S1. Pretreatment of waste fiber: Soak 5g of waste paper after crushing in 8% NaOH solution at 85℃ for 1 hour to remove the wax on the surface of the fiber. After taking it out, wash it with a large amount of secondary water until the washing liquid is neutral , And then put it in a vacuum oven at 40℃ to dry;

[0037] S2. Ozone treatment: Put the sample processed in step S1 into the ozone generator, react for 30 minutes, and then perform vacuum degassing at room temperature for 30 minutes to remove the adsorbed ozone and oxygen, and then add 3 g of acrylic monomer, together with the raw materials Put it into the polymerization tube, add 500ml of deionized water, deoxidize with nitrogen, heat at 60℃ for 2h, take out the material, rinse and soak with distilled water until its weight does not change;

[0038] S3. Alternate dipping: dipping the waste fiber processed in step S2 in 0.3mol / L CaCl 2 In the solution for 10s, after taking it out, rinse with water for 10s, then immerse ...

Embodiment 2

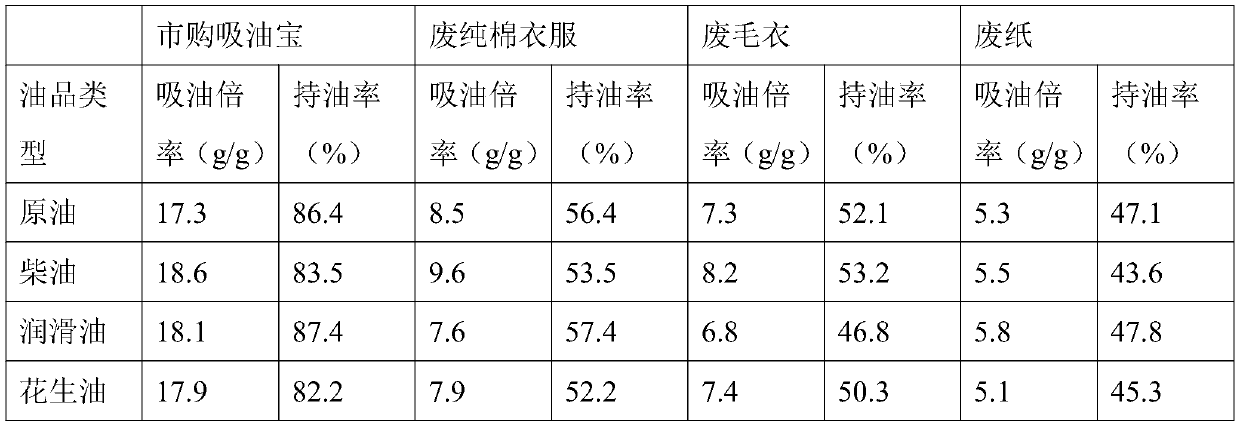

[0045] In the pretreatment of waste fiber in step S1, the raw material is replaced with crushed 5g waste sweater. The remaining steps are the same as in Example 1. The oil absorption ratio of the waste fiber oil-absorbing material prepared in this example in various oils and water is measured And oil holding rate is shown in Table 3:

[0046] table 3

[0047] Oil type Oil absorption rate (g / g) Oil retention rate (%) crude23.597.4 Diesel oil21.396.6 lubricating oil20.097.5 Peanut oil 20.897.1

[0048] Comparing the data in Table 1 and Table 3, it can be seen that using waste sweaters as raw materials, the waste fiber oil-absorbing material prepared by this method has an oil absorption rate of more than 20g / g and an oil retention rate of about 97%. The oil hydrophobicity is significantly improved. Compared with the unmodified waste sweater, the oil absorption rate and oil retention rate of the waste sweater oil-absorbing material prepared after the modification by this method...

Embodiment 3

[0050] In the pretreatment of waste fiber in step S1, the raw material is replaced with crushed 5g waste pure cotton clothes. The rest of the steps are the same as in Example 1. The waste fiber oil-absorbing material prepared in this example is measured in various oils and water. The oil absorption rate and oil holding rate are shown in Table 4:

[0051] Table 4

[0052] Oil type Oil absorption rate (g / g) Oil retention rate (%) crude27.396.4 Diesel oil25.798.1 lubricating oil22.398.2 Peanut oil 22.296.8

[0053] Comparing the data in Table 1 and Table 4, it can be seen that using waste pure cotton clothes as raw materials, the oil absorption rate of the waste fiber oil absorbing material prepared by this method all reaches above 22g / g, and the oil retention rate is 96%. Above, the lipophilic and hydrophobic properties are significantly improved. Compared with unmodified waste cotton clothes, the oil absorption rate and oil retention rate of the waste sweater oil-absorbing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com