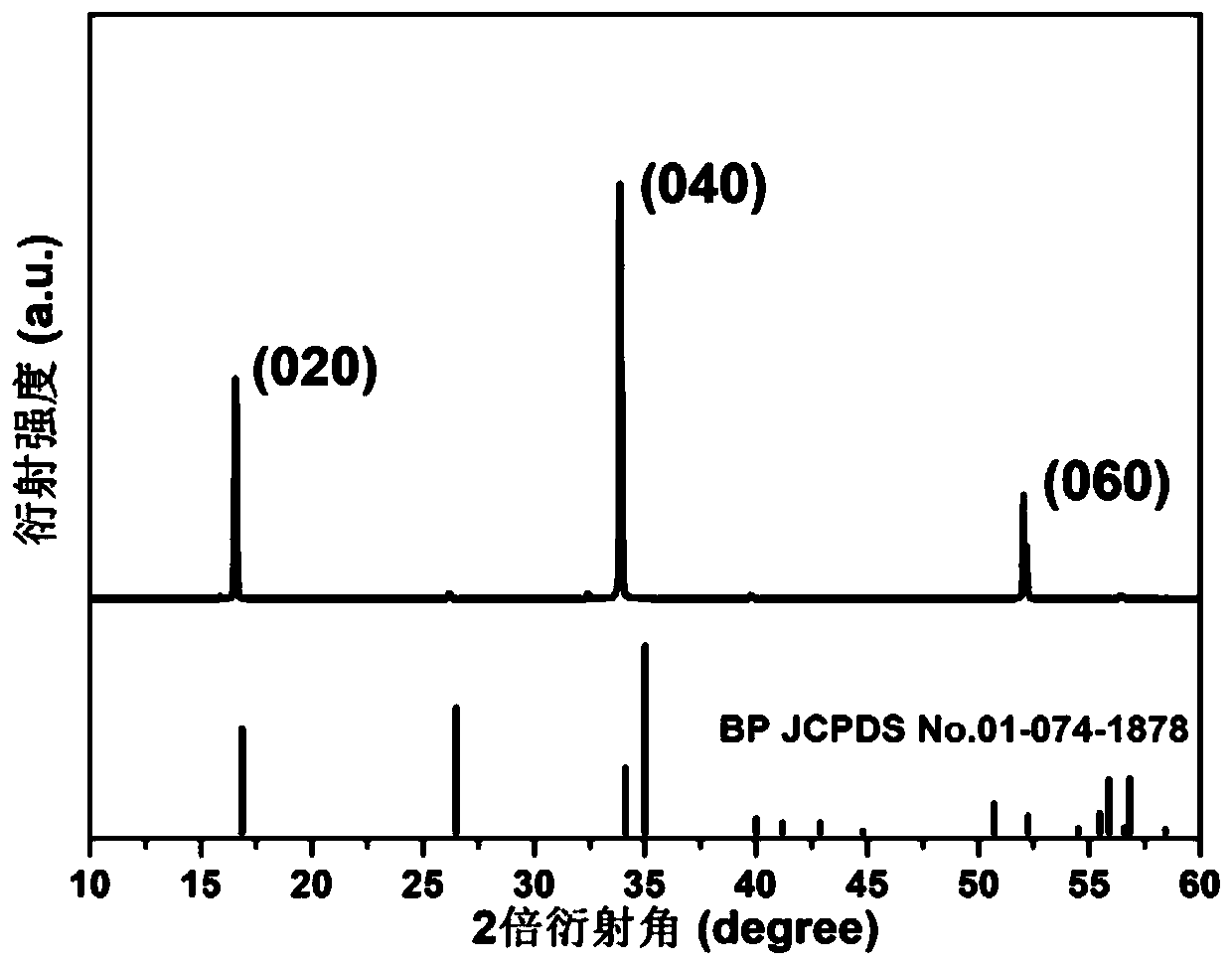

Method for rapidly preparing high-quality two-dimensional black phosphorus crystals through seed crystal induction

A high-quality, black phosphorus technology, applied in the field of two-dimensional materials, can solve the problems of harsh reaction conditions of black phosphorus crystals, the inability to prepare in large quantities, and the difficulty of mass production, etc., to achieve industrial-scale preparation and accelerated nucleation Effects on growth process, reduction of reaction temperature and reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for quickly preparing high-quality two-dimensional black phosphorus crystals by seed induction, the specific preparation steps are as follows:

[0050] 1) Under an inert atmosphere, weigh 310 mg of red phosphorus raw material, 6 mg of metal elemental tin, and 3 mg of iodine as a transport agent at the bottom of a single-head sealed quartz tube (raw material end, hot end); use a porous quartz gasket to separate, and weigh black Phosphorus seed crystal 8mg is placed on the top of the single-head sealed quartz tube (nucleation end, cold end); and the opening is sealed with a parafilm for later use;

[0051] 2) Remove the sealing film, and quickly use the vacuum sealing system to seal the reaction raw materials inside the quartz tube.

[0052] 3) Put the sealed quartz tube in the muffle furnace, and set the heating and cooling program as follows: at room temperature, after the temperature rises to 440°C for 1 hour, keep it warm for 6 hours; then start to cool down,...

Embodiment 2

[0055] A method for quickly preparing high-quality two-dimensional black phosphorus crystals by seed induction, the specific preparation steps are as follows:

[0056] 1) Under an inert atmosphere, weigh 3100 mg of red phosphorus raw material, 100 mg of bismuth as a metal element, and 60 mg of iodine as a transport agent at the bottom of a single-head sealed quartz tube (raw material end, hot end); use alumina porous gaskets for separation, and weigh 160 mg of black phosphorus seed crystals are placed on the top of the single-head sealed quartz tube (nucleation end, cold end); and the opening is sealed with a parafilm for subsequent use;

[0057] 2) Remove the sealing film, and quickly use the vacuum sealing system to seal the reaction raw materials inside the quartz tube.

[0058] 3) Put the sealed quartz tube in the muffle furnace, and set the heating and cooling program as follows: at room temperature, after the temperature rises to 520°C for 1 hour, keep it warm for 8 hour...

Embodiment 3

[0061] A method for quickly preparing high-quality two-dimensional black phosphorus crystals by seed induction, the specific preparation steps are as follows:

[0062] 1) Under an inert atmosphere, weigh 3100 mg of red phosphorus raw material, 105 mg of metal indium and 65 mg of tin tetraiodide as a transport agent at the bottom of a single-head sealed quartz tube (raw material end, hot end); use alumina porous gaskets for separation , take 100 mg of black phosphorus seed crystals on the top of a single-head sealed quartz tube (nucleation end, cold end); and seal the opening with a parafilm for subsequent use;

[0063] 2) Remove the sealing film, and quickly use the vacuum sealing system to seal the reaction raw materials inside the quartz tube.

[0064] 3) Put the sealed quartz tube in the muffle furnace, and set the heating and cooling program as follows: at room temperature, after the temperature rises to 480°C for 1 hour, keep it warm for 7 hours; , down to 280°C for 7h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com