Method for cooling high-temperature turbine blade by utilizing supercritical characteristics of working medium

A turbine blade, supercritical technology, applied in the direction of blade support elements, engine elements, machines/engines, etc., can solve the problems of reducing the flow of working medium, increasing the amount of cooling gas, reducing the reliability of the blades, and improving the efficiency of the turbine. , Increase the temperature before the turbine, improve the effect of working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

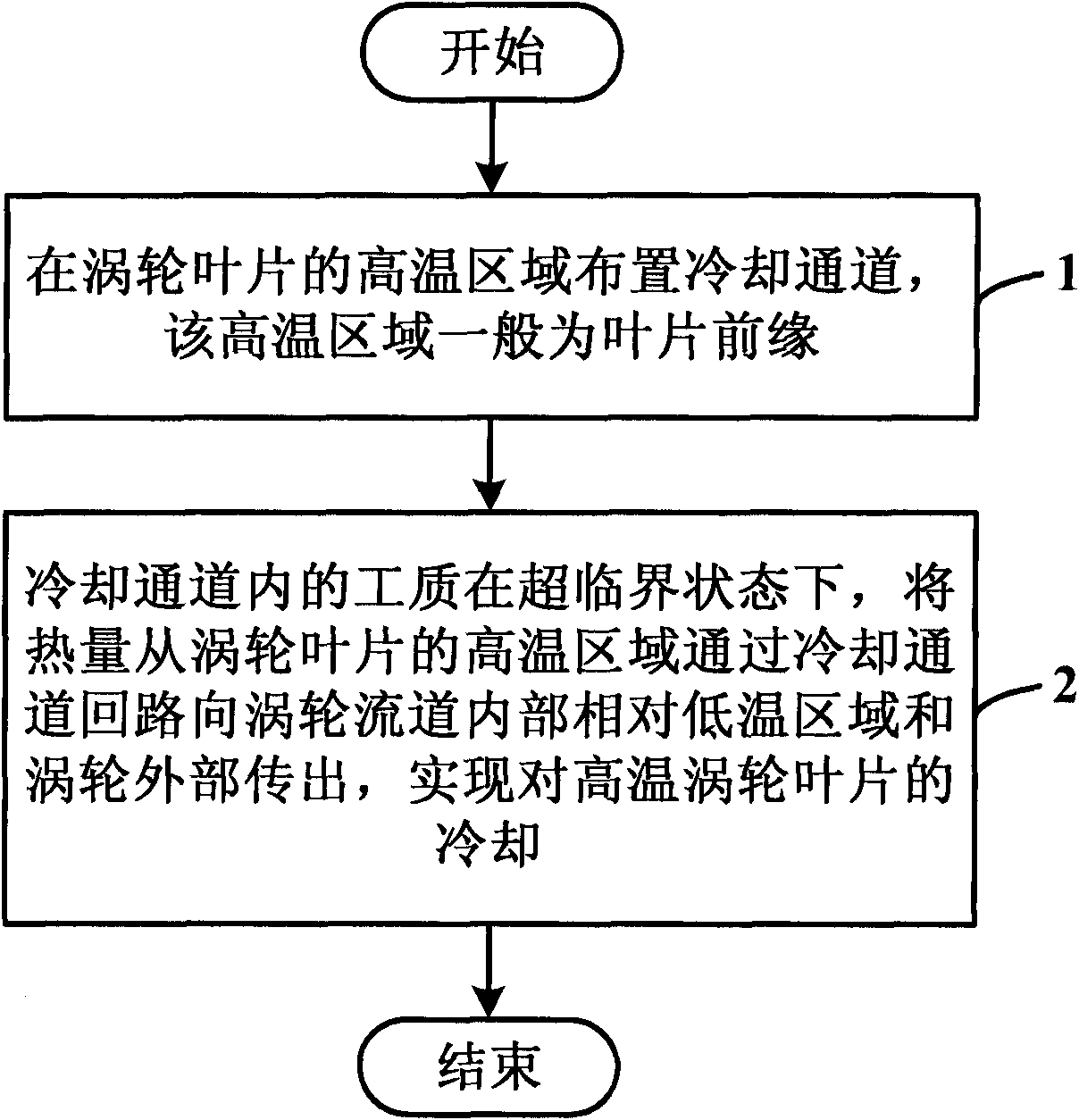

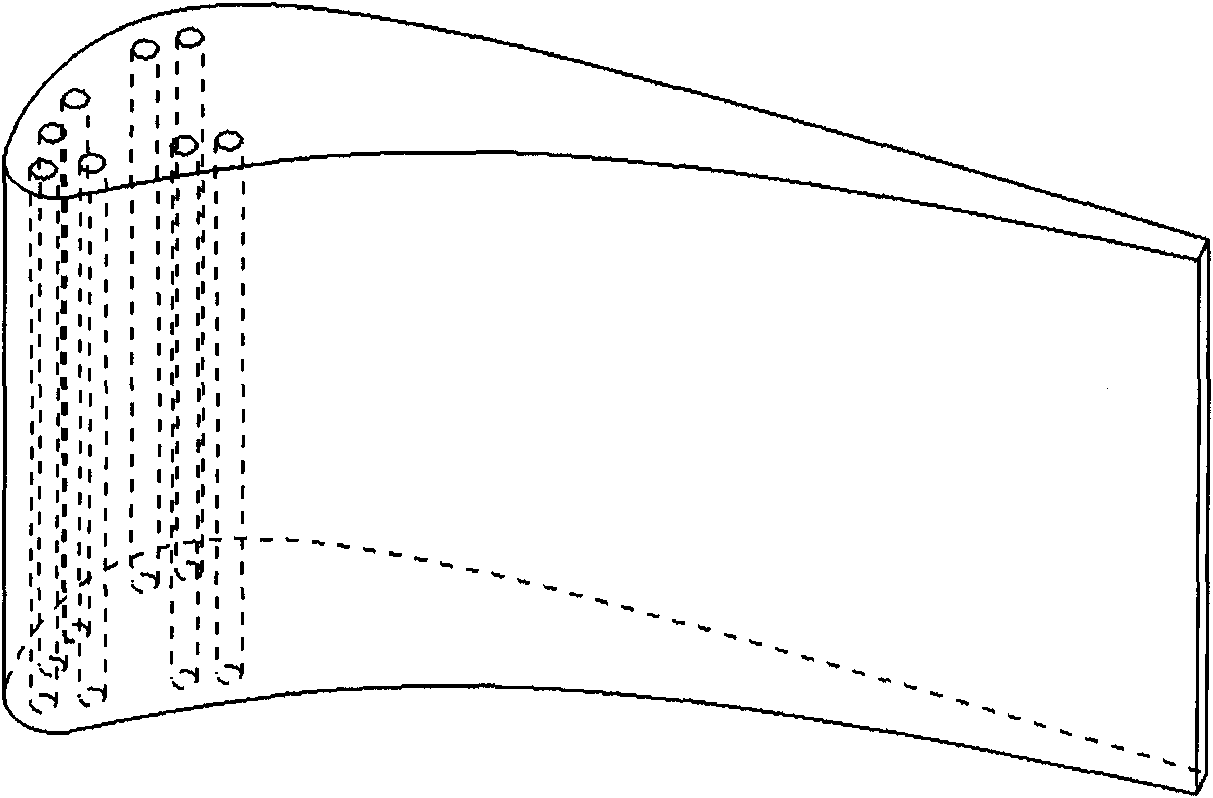

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0029] In the supercritical state, the fluid (working fluid) will experience rapid changes in density, viscosity, solubility, heat capacity, dielectric constant and other physical properties. At this time, the fluid has excellent fluidity and heat transfer. The present invention is a novel cooling method applied to blade cooling by utilizing the characteristic of fluid in a supercritical state. The invention utilizes the characteristics of rapid heat exchange and high efficiency of the working fluid in the supercritical state to cool the turbine blades, without or can reduce the introduction of the mainstream cooling airflow, thereby improving the working ability and efficiency of the turbine, and reducing the complexity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com