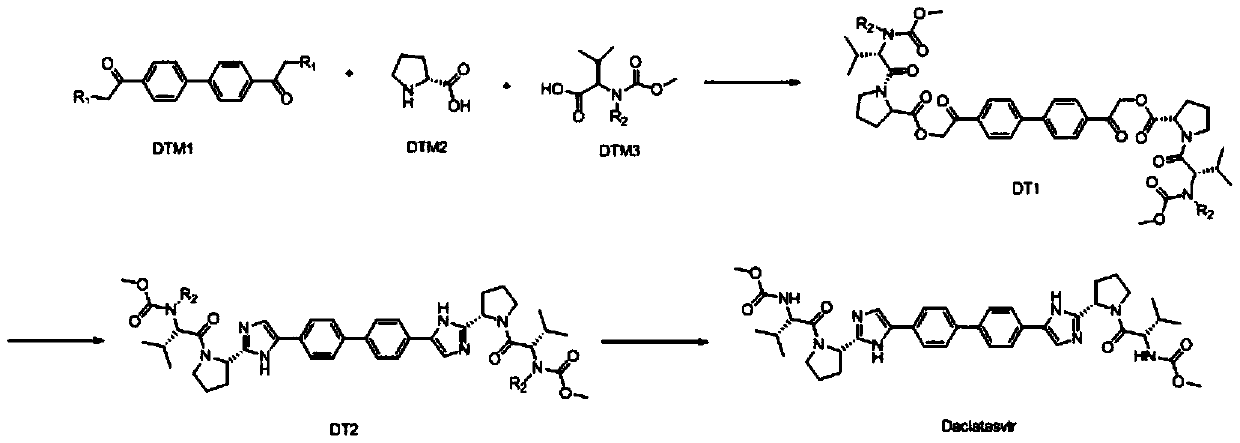

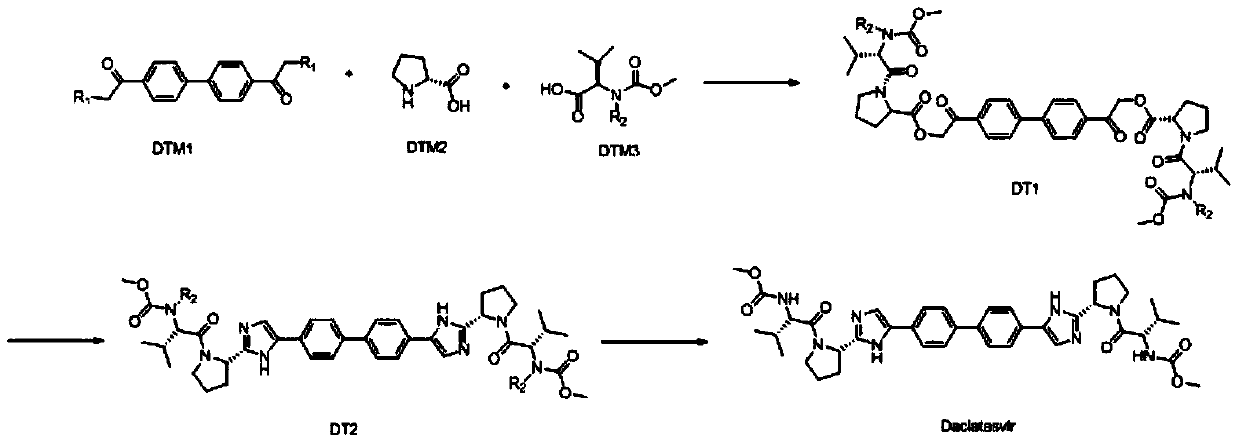

One-pot preparation technology of NS5A protein inhibitor daclatasvir

A protein inhibitor, daclatasvir technology, applied in the field of drug synthesis, can solve the problems of a lot of industrial waste, high cost, weakened route safety and operability, etc., to achieve high product yield and guaranteed safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1, preparation of DT1:

[0029] Add 4,4'-bis(2-chloroacetyl)biphenyl (DTM1) (15g, 49mmol, 1.0eq), L-proline (DTM2) (5.7g, 50mmol, 1.02eq) into a 1000mL reaction flask , Potassium carbonate (13.5g, 98mmol, 2.0eq) and 500mL tetrahydrofuran, stirred, heated up to 30-35°C for reaction, and monitored by TLC. When TLC showed that the raw material DTM1 reaction remained below 2%, it was lowered to 0-5°C, then EDCI (14.2g, 74mmol, 1.5eq) and HOBt (10g, 74mmol, 1.5eq) were added, stirred for 30 minutes, and then added (R )-2-[tert-butoxycarbonyl(methoxyformyl)amino]-3-methylbutanoic acid (DTM3) (13.8 g, 50 mmol, 1.02 eq). After the addition was completed, the temperature was raised to 20-25°C for reaction, and the reaction was monitored by TLC. After the reaction is complete, cool to room temperature, add 400mL of water and 600mL of ethyl acetate, stir, let stand for liquid separation, extract the aqueous layer with ethyl acetate (200mL×3), combine the organic phases, and...

Embodiment 2

[0035] Step 1, preparation of DT1:

[0036] Add 4,4'-bis(2-bromoacetyl)biphenyl (DTM1) (15g, 38mmol, 1.0eq), L-proline (DTM2) (4.6g, 40mmol, 1.05eq) into a 1000mL reaction flask , N,N-diisopropylethylamine (15.5g, 120mmol, 3.0eq) and 400mL acetonitrile, stirred, heated to 30-35°C for reaction, and monitored by TLC. TLC showed that when the raw material DTM1 reaction remained below 2%, it was lowered to 0-5°C, then DCC (19.6g, 95mmol, 2.5eq) and HOBt (12.8g, 95mmol, 2.5eq) were added, stirred for 30 minutes, and then added ( R)-2-[Benzoyl(methoxyformyl)amino]-3-methylbutanoic acid (DTM3) (11.2 g, 40 mmol, 1.05 eq). After the addition was completed, the temperature was raised to 20-25°C for reaction, and the reaction was monitored by TLC. After the reaction is complete, cool to room temperature, add 300mL of water and 500mL of ethyl acetate, stir, let stand for liquid separation, extract the aqueous layer with ethyl acetate (200mL×3), combine the organic phases, and wash with ...

Embodiment 3

[0042] Step 1, preparation of DT1:

[0043] Add 4,4'-bis(2-chloroacetyl)biphenyl (DTM1) (20g, 65mmol, 1.0eq), L-proline (DTM2) (7.7g, 69mmol, 1.05eq) into a 1000mL reaction flask , cesium carbonate (42.4g, 130mmol, 2.0eq) and 600mL tetrahydrofuran, stirred, heated to 30-35°C for reaction, and monitored by TLC. When TLC showed that the raw material DTM1 reaction remained below 2%, it was lowered to 0-5°C, then CDI (21.1g, 130mmol, 2.0eq) and HOBt (17.6g, 130mmol, 2.0eq) were added, stirred for 30 minutes, and then added ( R)-2-(benzyloxycarbonyl (methoxyformyl)amino-3-methylbutanoic acid (DTM3) (20.7g, 67mmol, 1.03eq). After addition, the temperature was raised to 20-25°C for reaction, and the reaction was monitored by TLC After the reaction is complete, cool to room temperature, add 500mL of water and 600mL of ethyl acetate, stir, let stand for liquid separation, extract the aqueous layer with ethyl acetate (200mL×3), combine the organic phases, and wash with saturated brine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com