Application of a Low Phosphorus-Containing Crosslinking Agent in the Preparation of Polyurethane Films

A polyurethane film and cross-linking agent technology, which is applied in the application field of low phosphorus-containing cross-linking agent in the preparation of polyurethane film, can solve the problems of poor flame retardancy, long curing time, and unfavorable environmental protection of polyurethane, and achieve the goal of enhancing flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

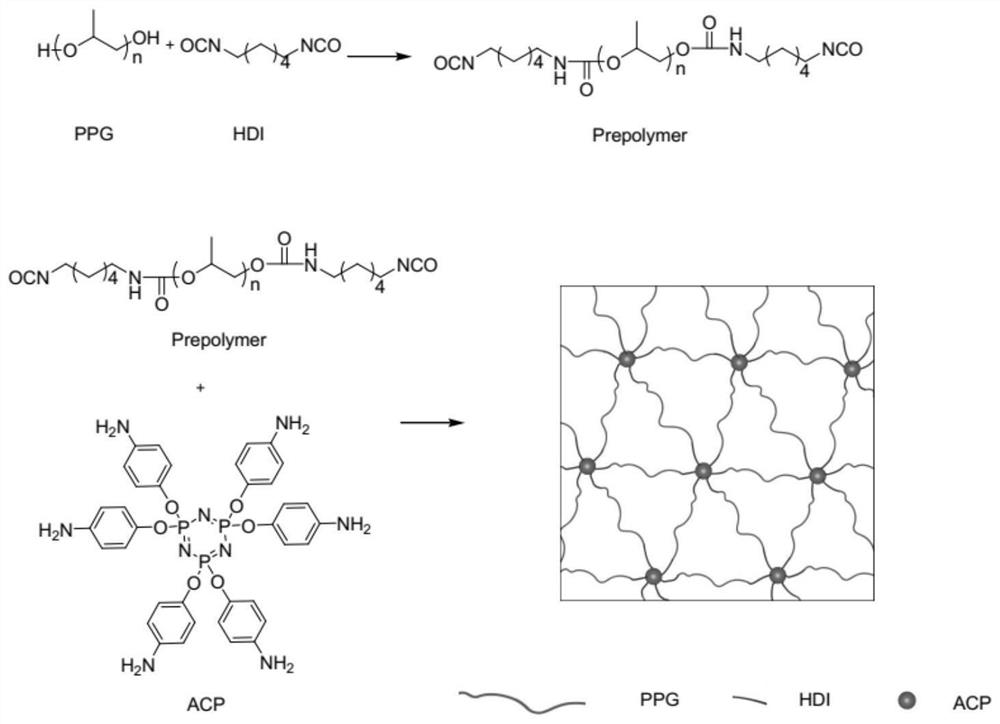

[0062] The synthesis of the cyclic phosphazene end-capped by cross-linking agent amino group, concrete steps are as follows:

[0063] (1) Synthesis of six (acetylaminophenyl) cyclotriphosphazenes

[0064] Take 1mmol of N 3 P 3 Cl 6 , 7.2mmol 4-acetylaminophenol, K of 10.8mmol 2 CO 3 , placed in 60mL of acetone solution and heated to reflux for 70-100h; then evaporate the volatile substances in the product under vacuum conditions, and wash the residue 3 times with 20mL of water each time; then wash 2 times with ethanol, each time with ethanol 5 mL; finally washed 3 times with hexane, each time with 5 mL of hexane, and vacuum-dried the obtained white solid I at 40°C to 60°C for 48 to 72 hours to obtain hexa(acetylaminophenyl)cyclotriphosphazene, such as Figure 11 , 13 shown.

[0065] (2) Synthesis of amino-terminated cyclophosphazenes

[0066] Add 0.5 mmol of hexa(acetylaminophenyl)cyclotriphosphazene and NaOH with a mass concentration of 44-45% into 20 mL of methanol s...

Embodiment 2

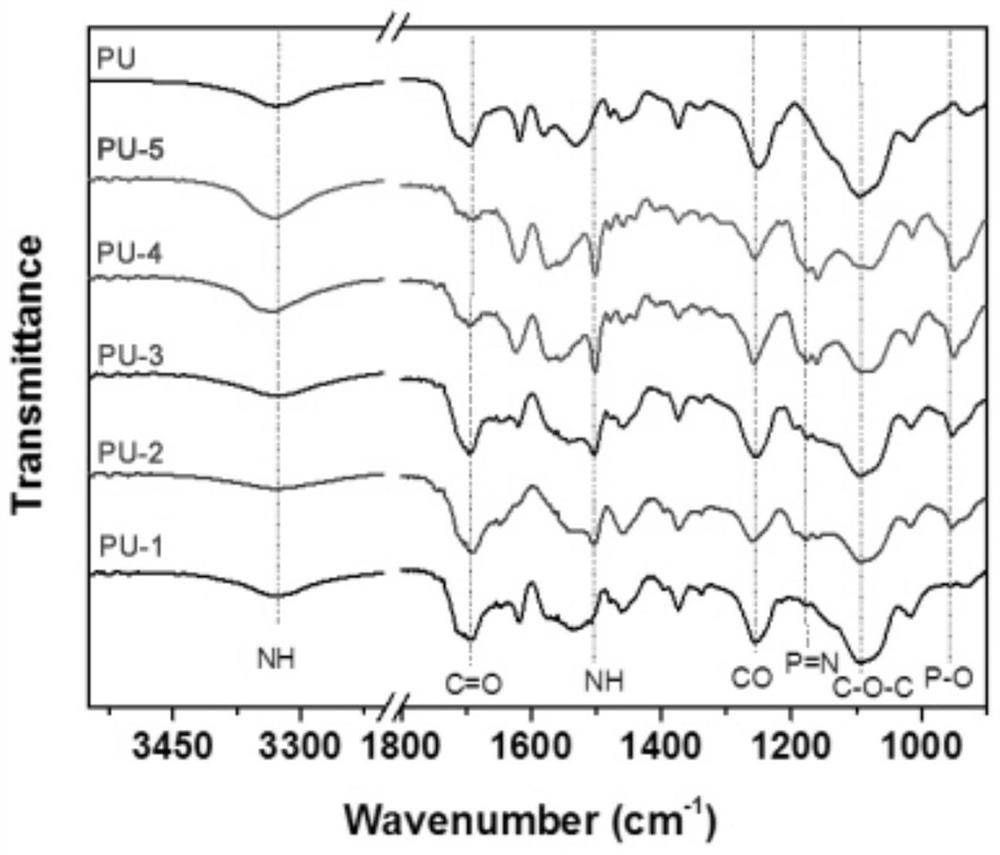

[0069] Synthesis of Pure Polyurethane Films

[0070] 2 mmol of hexamethylene diisocyanate and 1 mmol of polypropylene glycol 400 were mixed and heated at 65° C. for 60 minutes in a nitrogen atmosphere to obtain a prepolymer;

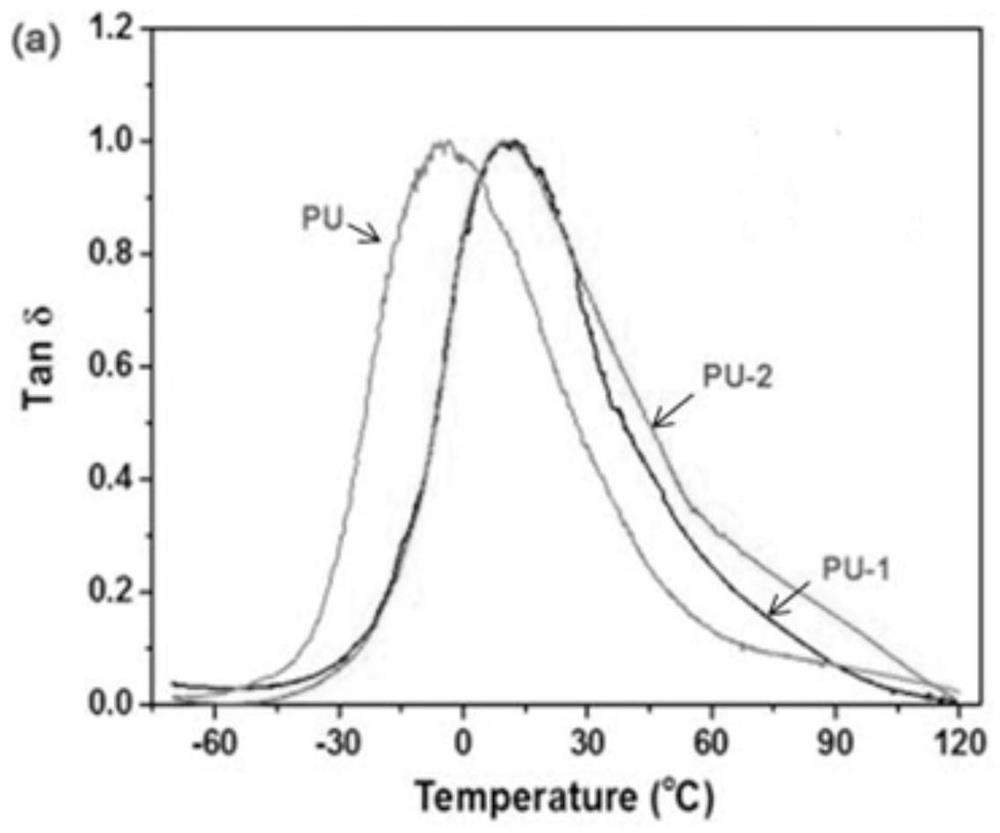

[0071] Then 5wt.% tris(2-aminoethyl)amine was dissolved in 15mL of N,N-dimethylformamide, the resulting solution was added to the prepolymer, and magnetically stirred evenly; then the solution was cast into On the PTFE mold, the solvent is evaporated, and the evaporated liquid layer is cross-linked at 60° C. for 48 hours. After cross-linking, the final product, a horizontally crossed polyurethane film, is denoted as PU.

Embodiment 3

[0073] Synthesis of Polyurethane Films

[0074] Mix 2mmol hexamethylene diisocyanate and 1mmol polypropylene glycol 400 and heat at 65°C for 60 minutes in a nitrogen atmosphere to obtain a prepolymer; then dissolve 5wt.% amino-terminated cyclophosphazene in N,N - In dimethylformamide, add the obtained solution to the prepolymer, stir evenly, cast the solution on a PTFE mold, evaporate the solvent, and cross-link the evaporated liquid layer at 60°C for 48h, and then obtain the final product Flat cross polyurethane film, denoted as PU-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com