A kind of memory nylon rubber-plastic material and preparation method thereof

A memory, modified nylon technology, applied in the field of plastic materials, can solve the problems of insufficient product elasticity and softness, insufficient folding resistance, insufficient elasticity, poor dimensional stability, etc., to improve comprehensive mechanical properties, convenient processing, and enhanced low temperature The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

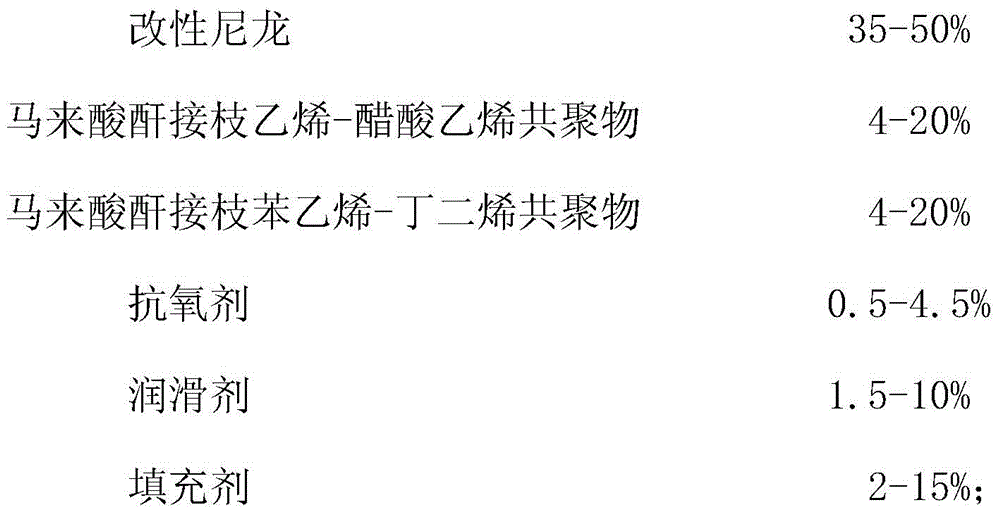

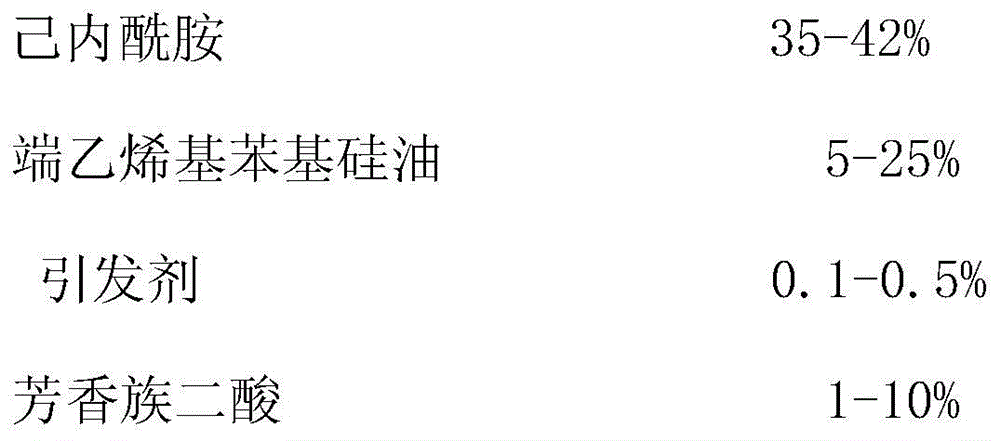

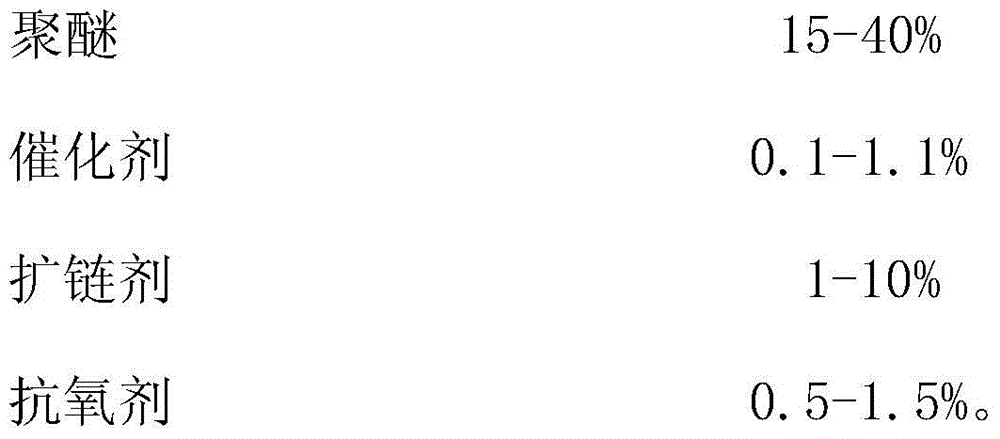

[0031] The memory nylon rubber-plastic material provided in this embodiment is made of the following composition by weight percentage:

[0032]

[0033]

[0034] Wherein, described modified nylon is made of the following components by weight percentage:

[0035]

[0036] The maleic anhydride graft ratio in the described maleic anhydride grafted ethylene-vinyl acetate copolymer and maleic anhydride grafted styrene-butadiene copolymer is 1.6%.

[0037] The antioxidant is antioxidant 1010 or 1098; the lubricant is calcium stearate; the filler is one or more of calcium carbonate, silicon dioxide, carbon black; the The catalyst is one or more of triphenyl phosphite and organotin; the initiator is 2,2-bis-(tert-butylperoxy)propane.

[0038] The vinyl-terminated phenyl silicone oil contains 0.15-0.45% of vinyl groups.

[0039] The polyether is one or more of polytetrahydrofuran ether glycol and polytrimethylene ether glycol.

[0040] The aromatic diacid is one or both of ...

Embodiment 2

[0049] The memory nylon rubber-plastic material provided in this embodiment and its preparation method are basically the same as in Example 1, except that:

[0050] A memory nylon rubber-plastic material, made of the following composition by weight percentage:

[0051]

[0052] Wherein, described modified nylon is made of the following components by weight percentage:

[0053]

[0054] The maleic anhydride graft ratio in the described maleic anhydride grafted ethylene-vinyl acetate copolymer and maleic anhydride grafted styrene-butadiene copolymer is 1.6%.

[0055] Described antioxidant is antioxidant 1010; Described lubricant is calcium stearate; Described filler is calcium carbonate; Described catalyst is triphenyl phosphite; Described initiator is 2 , 2-bis-(tert-butyl peroxide) propane.

[0056] The vinyl-terminated phenyl silicone oil contains 0.15% vinyl group.

[0057] The polyether is polytetrahydrofuran ether glycol.

[0058] The aromatic diacid is isophthal...

Embodiment 3

[0067] The memory nylon rubber-plastic material provided in this embodiment and its preparation method are basically the same as those in Examples 1 and 2, except that:

[0068] A memory nylon rubber-plastic material, made of the following composition by weight percentage:

[0069]

[0070] Wherein, described modified nylon is made of the following components by weight percentage:

[0071]

[0072]

[0073] In described maleic anhydride grafted ethylene-vinyl acetate copolymer, maleic anhydride grafted styrene-butadiene copolymer, maleic anhydride graft rate is 1.6%; Described antioxidant is antioxidant 1010 Described lubricant is calcium stearate; Described filler is carbon black; Described catalyst is organotin; Described initiator is 2,2-bis-(tert-butyl peroxide) propane; The vinyl-terminated phenyl silicone oil contains 0.25% vinyl; the polyether is polytrimethylene ether glycol; the aromatic diacid is terephthalic acid; the chain extender For bis (2-oxazoline)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com