Shape memory chitosan hydrogel and preparation method thereof

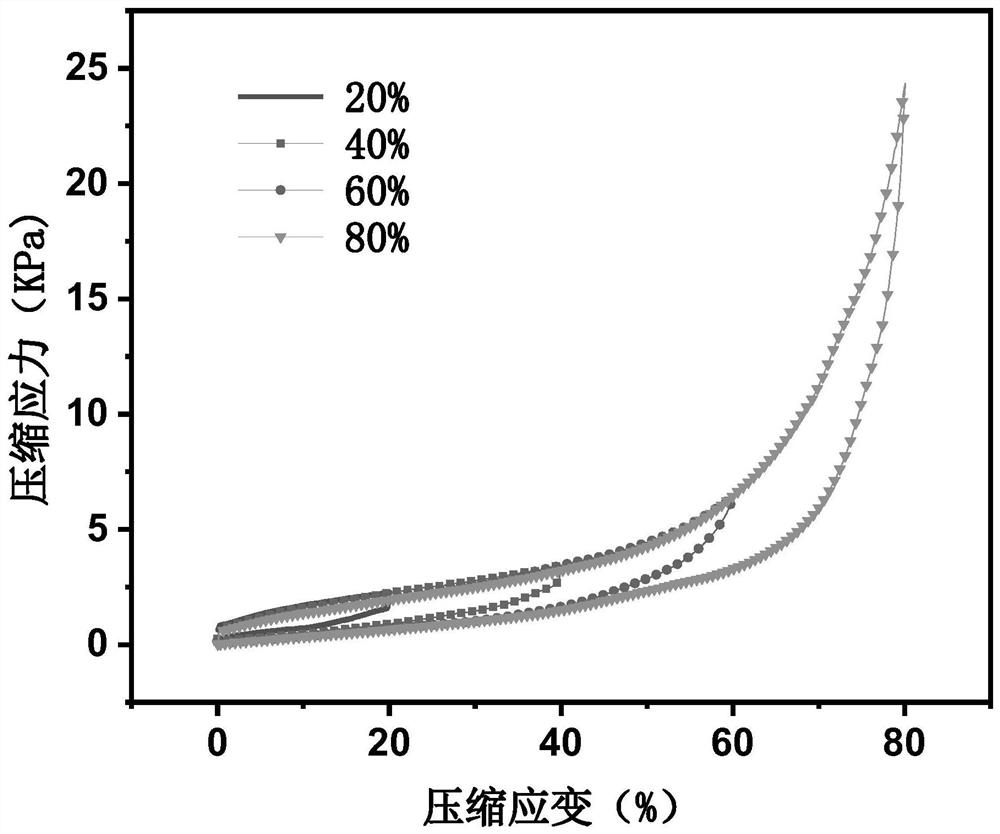

A technology of chitosan and chitosan fiber, which is applied in the field of material chemistry and natural polymers, can solve the problems of limited application, poor mechanical properties of chitosan-based hydrogel, etc., to improve mechanical properties and facilitate large-scale preparation , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Add 0.2g of chitosan to a beaker containing 99.8g of deionized water, add 0.2ml of glacial acetic acid dropwise during magnetic stirring, and continue stirring for 2 hours to obtain a chitosan solution;

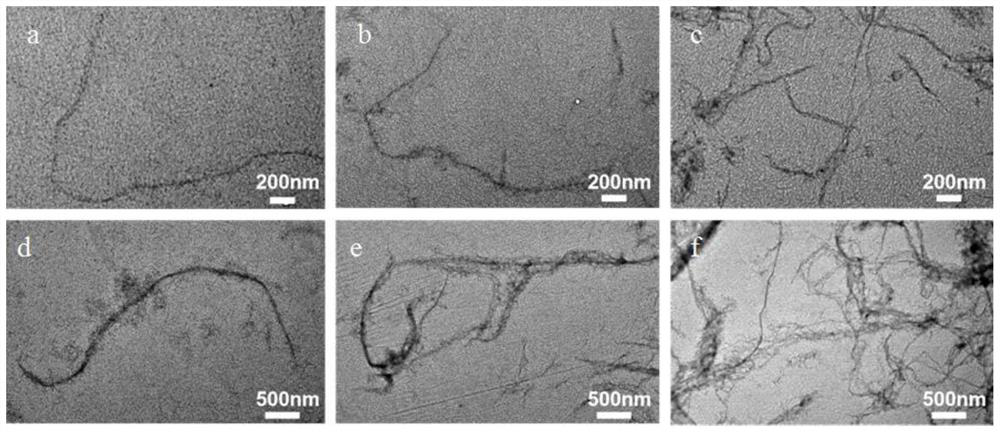

[0039] (2) Preparation of chitosan fiber bundle suspension with good stability. Use a homogenizer to stir the chitosan solution in step (1) at a speed of 2000 rpm, while adding a certain volume of Na 2 CO 3 Solution (0.5mol / L) makes pH reach 7; Stir 5min time to obtain stable white milky chitosan fiber bundle suspension;

[0040] (3) Add glutaraldehyde with a concentration of 20% to the white milky chitosan fiber bundle suspension described in step (2) (the mass ratio of glutaraldehyde to chitosan is 1:1), mix well, Obtain cross-linked chitosan fiber bundle suspension;

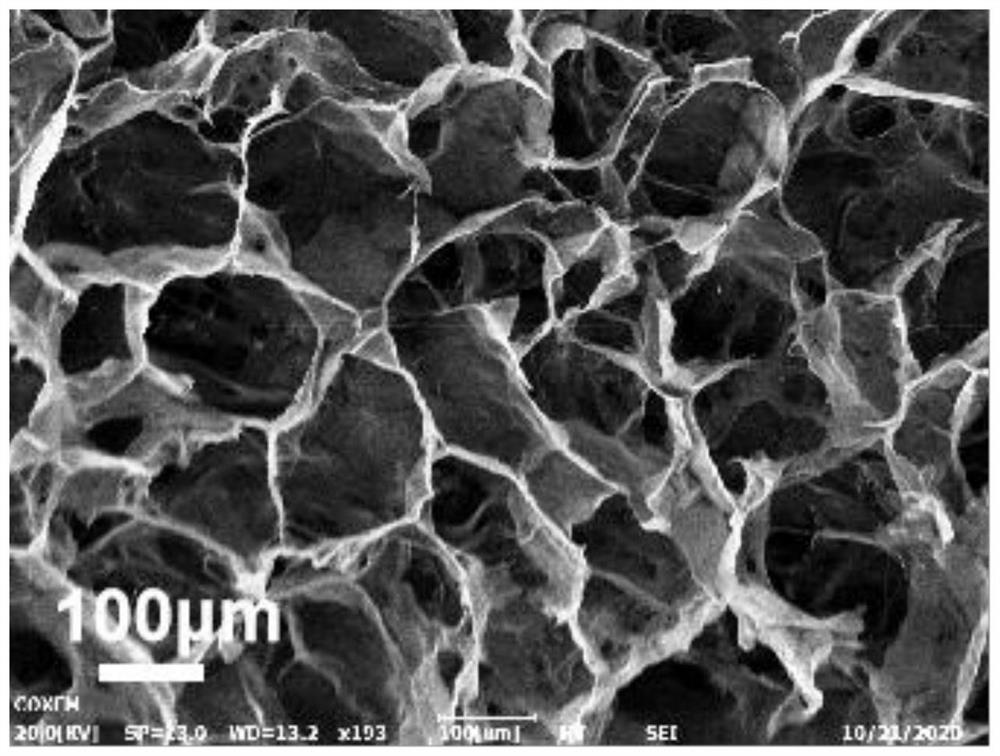

[0041] (4) Use a centrifuge to concentrate the suspension obtained in step (3) at a speed of 500 rpm, remove the supernatant to obtain a concentrated suspension of cross-linked chitosan fiber bu...

Embodiment 2

[0045] (1) Add 4g of chitosan to a beaker containing 96g of deionized water, add 1.5ml of concentrated hydrochloric acid dropwise during magnetic stirring, and continue stirring for 16 hours to obtain a chitosan solution;

[0046] (2) Preparation of chitosan fiber bundle suspension with good stability. Use a homogenizer to stir the chitosan solution in step (1) at a speed of 18000rpm, while adding a certain volume of K(OH) 2 Solution (0.5mol / L) makes pH reach 12; Stir 6min to obtain stable white milky chitosan fiber bundle suspension;

[0047] (3) Centrifuge and concentrate the white milky chitosan fiber bundle suspension obtained in step (2) at a speed of 10,000 rpm, remove the supernatant to obtain a concentrated chitosan fiber bundle suspension, and inject it into 6 holes In the polytetrafluoroethylene plate mold, the shape of each hole of the mold is the shape of the hydrogel to be prepared, and the amount added to each hole is 6ml.

[0048] (4) Place the 6-hole polytetr...

Embodiment 3

[0051] (1) Add 1g of chitosan to a beaker containing 99g of deionized water, add 0.45ml of glacial acetic acid dropwise during magnetic stirring, and continue stirring for 4 hours to obtain a chitosan solution;

[0052] (2) Preparation of chitosan fiber bundle suspension with good stability. Use a homogenizer to stir the chitosan solution in step (1) at a speed of 5000rpm, and add a certain volume of NaOH solution (1mol / L) dropwise to make the pH reach 14; stir for 8min to obtain stable white milky chitosan fibers beam suspension;

[0053] (3) Add epichlorohydrin (the mass ratio of epichlorohydrin to chitosan is 3:1) to the white milky chitosan fiber bundle suspension described in step (2), and mix evenly to obtain cross-linked Chitosan fiber bundle suspension;

[0054] (4) Centrifuge and concentrate the cross-linked chitosan fiber bundle suspension obtained in step (3) at a speed of 3000 rpm, remove the supernatant to obtain a concentrated cross-linked chitosan fiber bundle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com