Built-in permanent magnet synchronous motor control method

A technology of permanent magnet synchronous motor and control method, which is applied in the direction of motor generator control, electronic commutation motor control, control system, etc., and can solve the problems of no real-time and accurate use of motor parameters, motor torque accuracy, motor operating efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

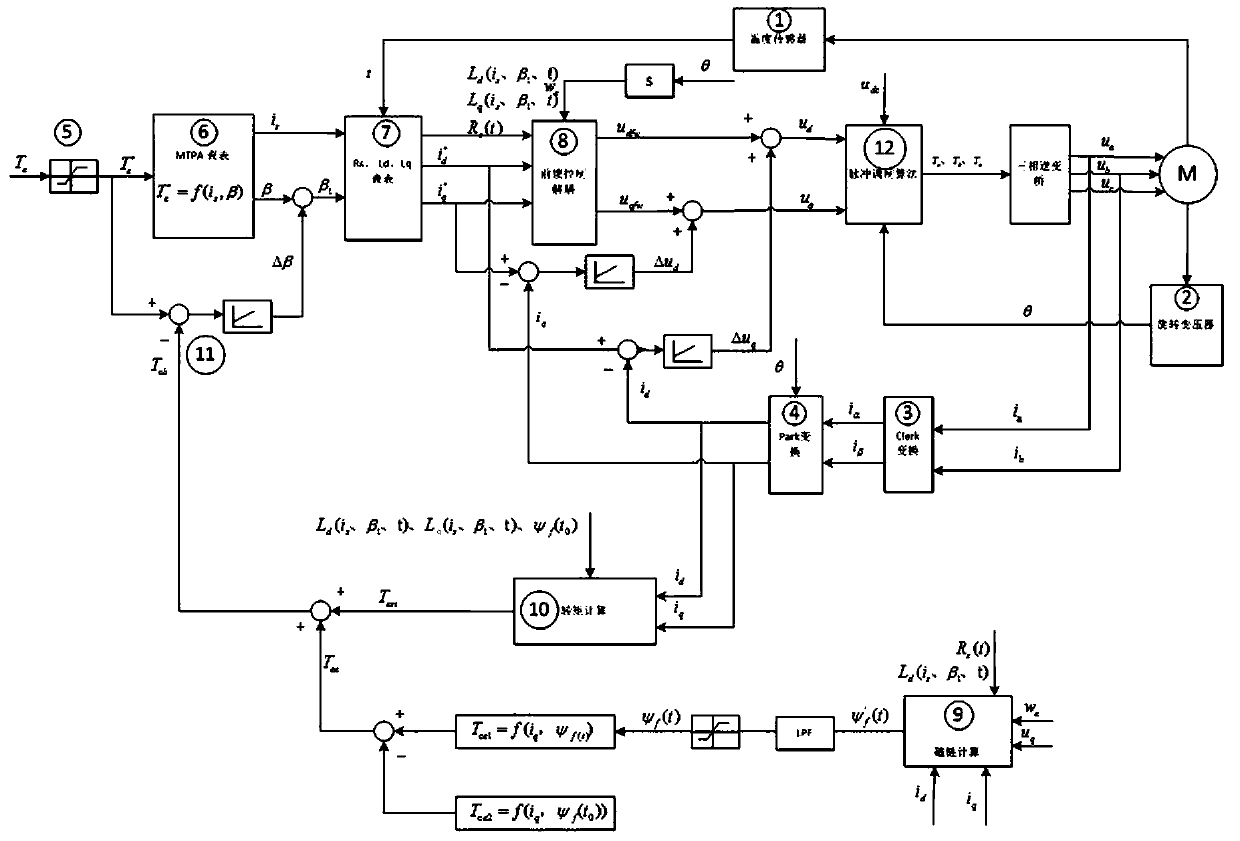

[0066] A control method for a built-in permanent magnet synchronous motor, which is divided into the following control modules (such as figure 1 Shown): temperature sensor module 1, resolver module 2, Clark transformation module 3, Park transformation module 4, torque command processing module 5, MTPA table lookup module 6, stator inductance and resistance parameter lookup table module 7, voltage calculation module , flux linkage calculation module 9, feedback torque calculation module 10, current vector angle adjustment module 11, pulse modulation module 12;

[0067] 1) Temperature sensor module

[0068] The temperature sensor is buried in the stator of the permanent magnet synchronous motor, and the real-time stator temperature t of the motor is collected by the temperature sensor.

[0069] 2) Resolver module

[0070] The resolver is installed on the permanent magnet synchronous motor, and the rotor position θ of the permanent magnet synchronous motor is acquired through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com