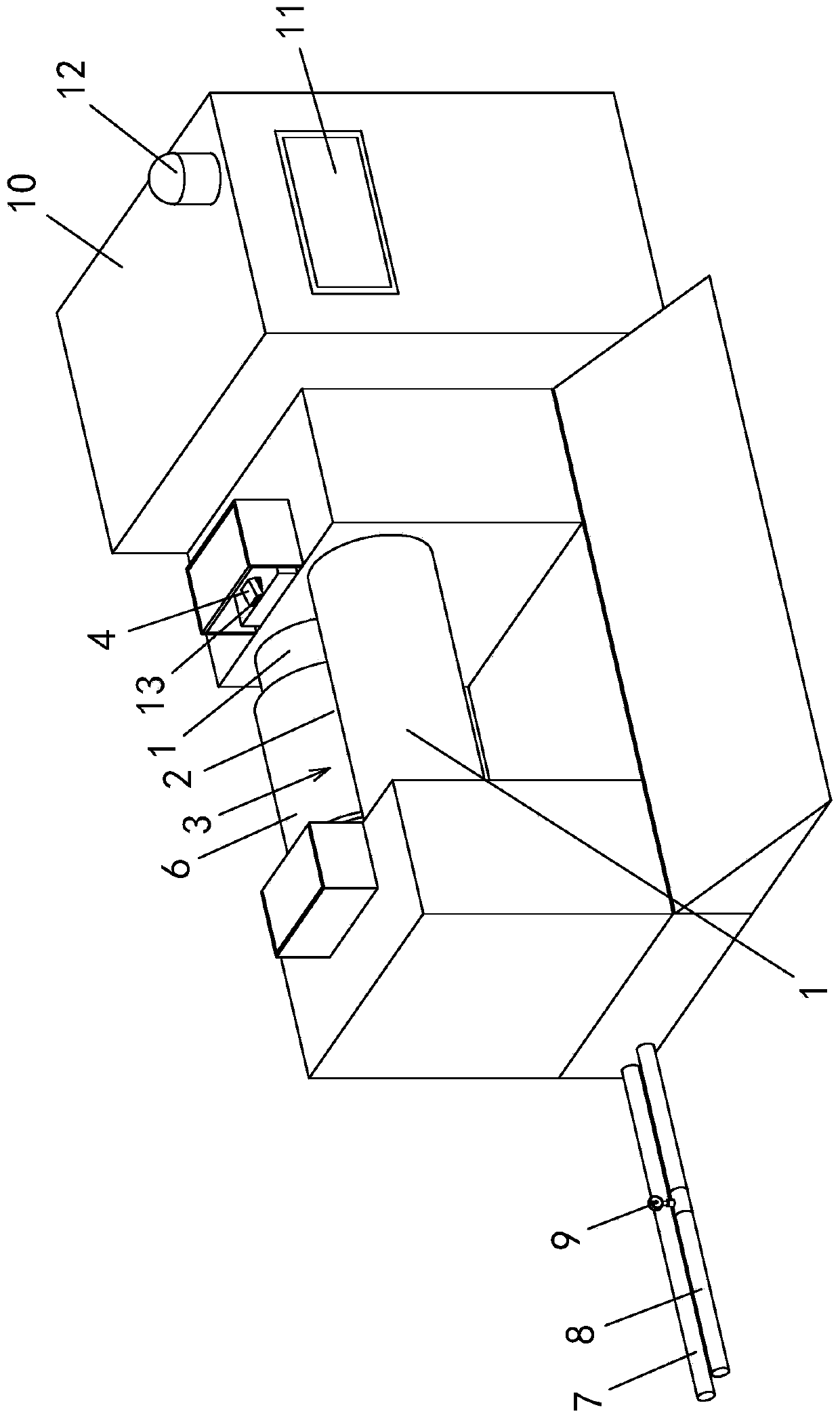

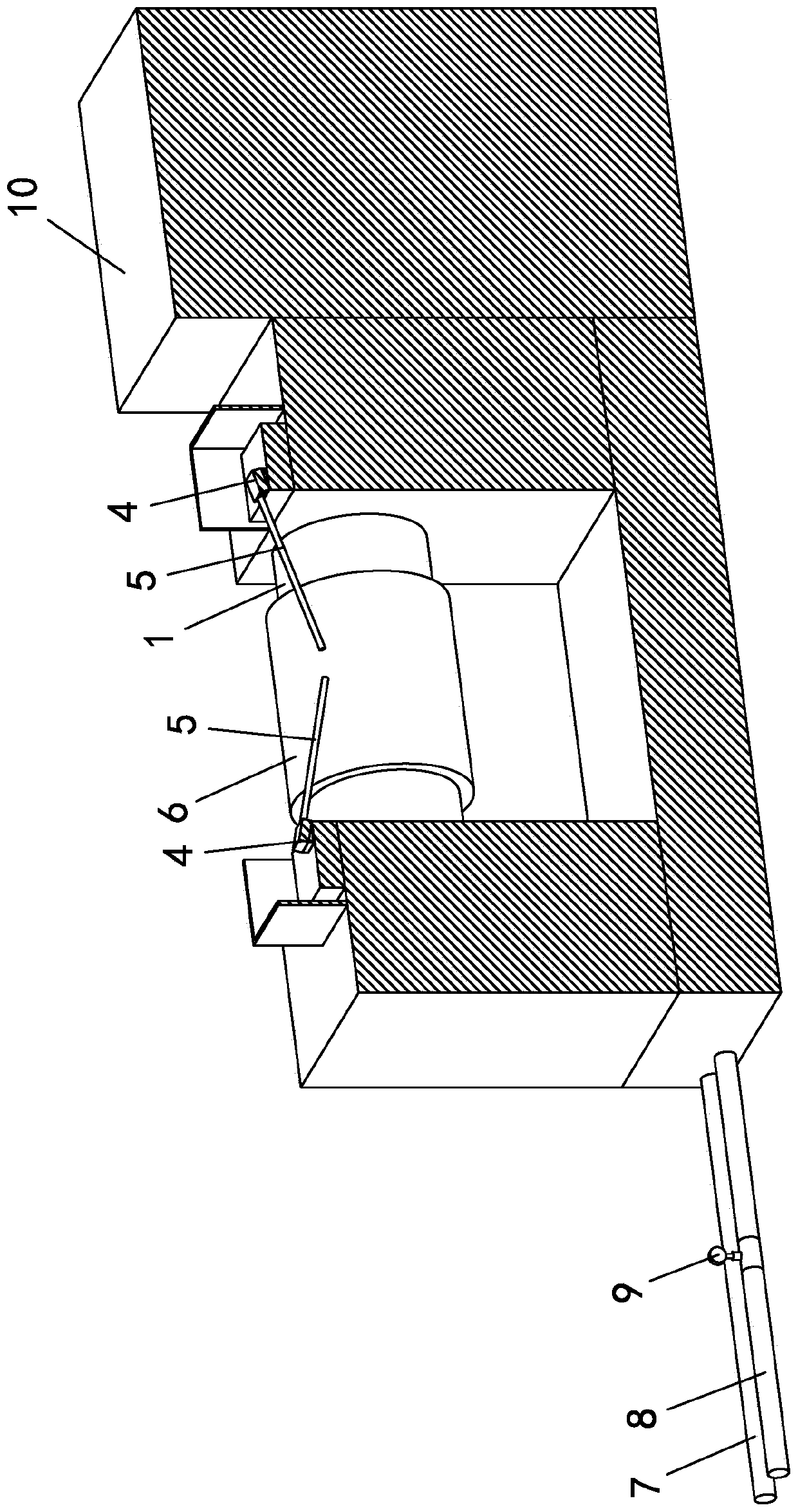

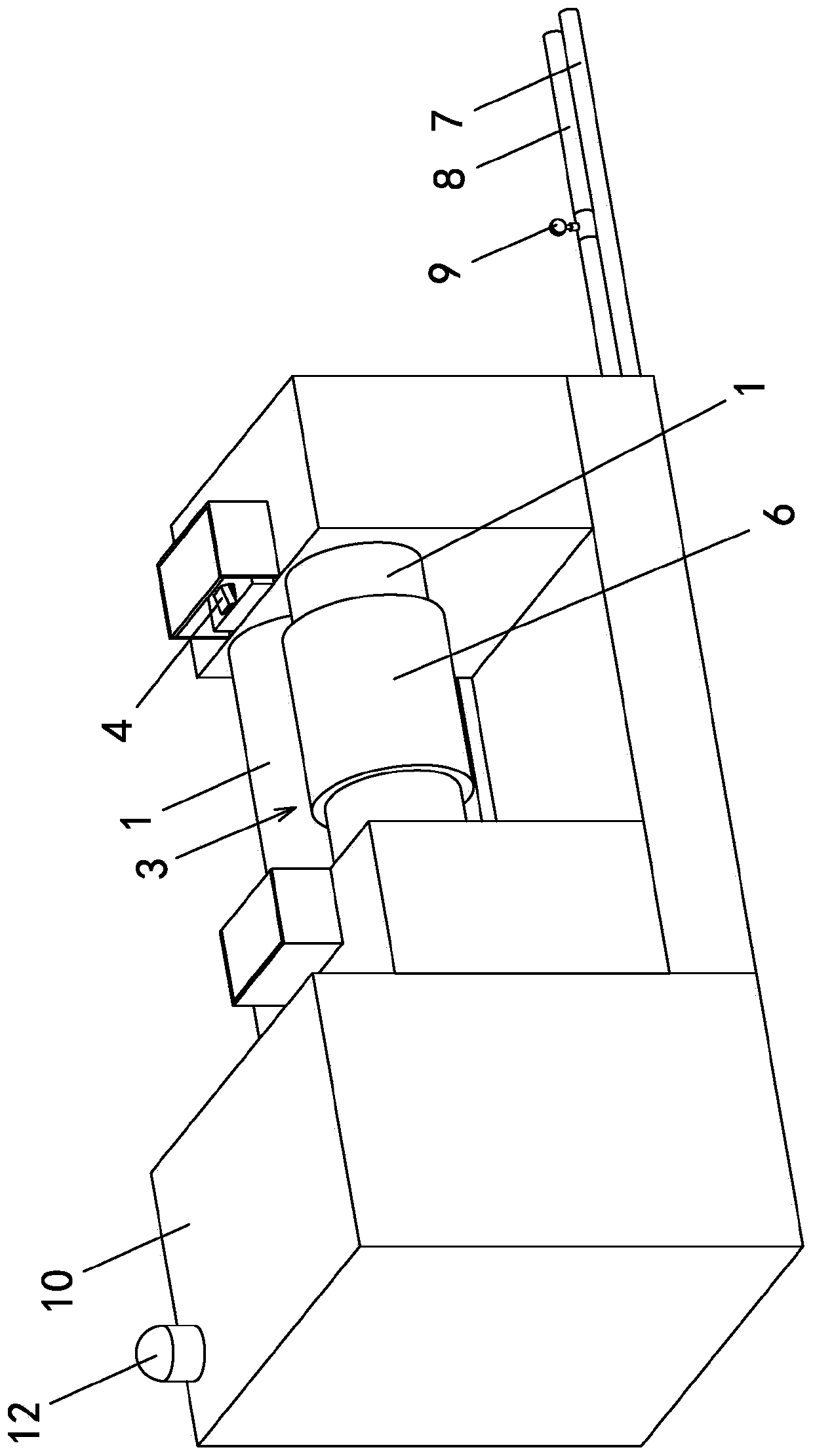

Novel silicon rubber mixing process control device

A silicone rubber and rubber mixing technology, applied in the field of silicone rubber mixing process control equipment, can solve the problems of surface temperature rise, precise control, and inability to achieve the number of times of rubber mixing, so as to reduce the impact and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Embodiment: The following will clearly illustrate this case with drawings and detailed descriptions. After any person skilled in the art understands the embodiment of this case, he can change and modify it by the technology taught in this case without departing from the spirit of this case. with range.

[0028] The terminology used herein is for the purpose of describing particular embodiments only, and is not intended to be limiting of the present case. Singular forms such as "a", "the", "the", "this" and "the", as used herein, also include plural forms.

[0029] As used herein, "connection" or "positioning" can mean that two or more components or devices are in direct physical contact with each other, or that they are in indirect physical contact with each other, or that two or more components or devices are in mutual operation. or action.

[0030] As used herein, "comprising", "comprising", "having" and the like are all open terms, meaning including but not limited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com