Plasma torch molten metal wire consumable material deposition extrusion 3D printing nozzle

A plasma torch and molten metal technology, applied in the field of metal 3D printing nozzles, can solve problems such as difficult effective combination, complicated operation and maintenance, and large heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below in conjunction with specific embodiment:

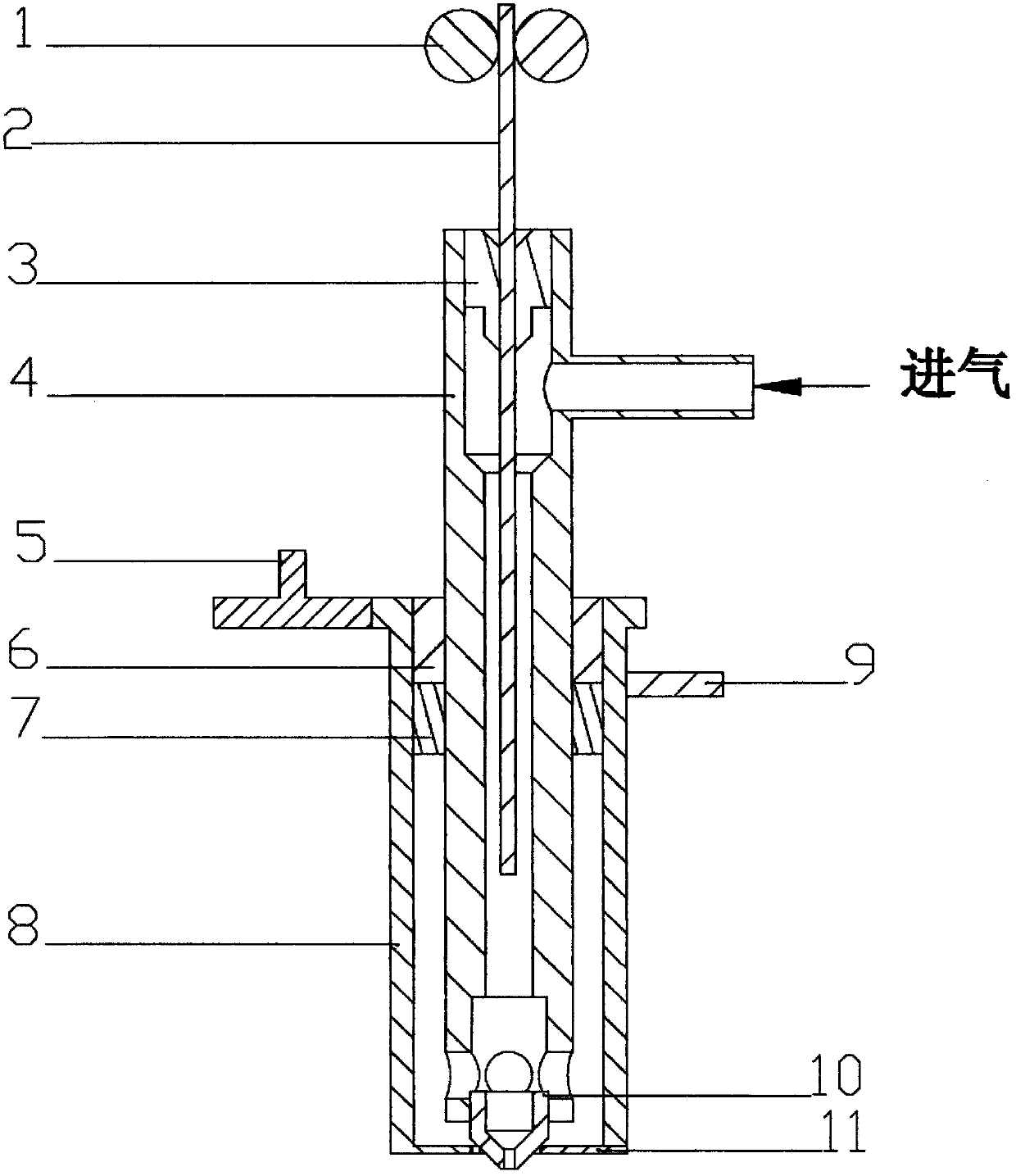

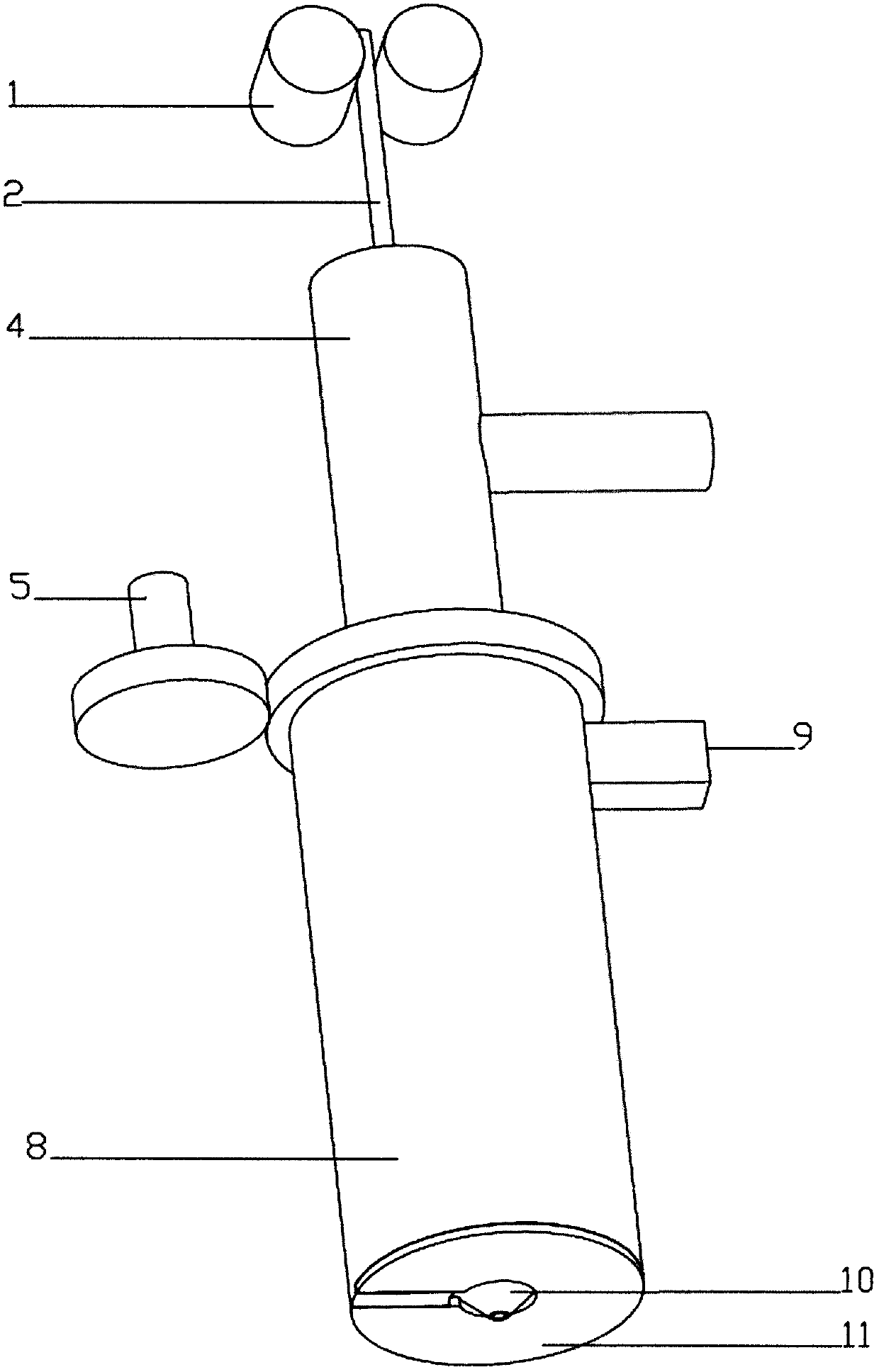

[0014] Such as figure 1 , 2 As shown, the feeding device 1 is driven by a control motor to feed the rollers, and is fixed on a fixed seat that can move on the X and Y axes.

[0015] The cathode feeding tube 4 is fixed on a fixed seat that can move on the X and Y axes.

[0016] The seal 3 is located between the cathode feed tube 4 and the wire consumable 2, and has high temperature resistant sealing properties to prevent gas leakage.

[0017] The sealing member 7 is located between the bearing 6, the anode 8, and the cathode feed pipe 4, and has high-temperature-resistant sealing properties to prevent gas leakage.

[0018] The shower head 10 is made of a metal material with low electron escape power and high temperature resistance, and is connected with the cathode feed pipe 4 .

[0019] The high-temperature insulating ring 11 is high-temperature-resistant and has go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com