A precise mixing system and method for vanadium titanium and ordinary iron fine powder

A technology for iron powder and vanadium-titanium-iron, which is applied in the field of precise mixing system of vanadium-titanium and ordinary iron powder, can solve the problems of large fluctuation range of chemical properties of sintered ore, poor flow properties, low drum index, etc. Overall physical and chemical properties, yield and weight improvements, effects of improved flow properties

Active Publication Date: 2022-05-31

HEBEI IRON AND STEEL

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Vanadium-titanium magnetite directly produced by vanadium-titanium-ferro fine powder has a wide range of chemical properties fluctuations, low drum index, high return rate and other defects, which plague the high-weight production of vanadium-titanium sinter

Moreover, pure vanadium-titanium sinter has poor fluidity in the process of reducing molten iron in the blast furnace, which is the main reason for the fluctuation of the blast furnace furnace ore, which causes great difficulties for subsequent steelmaking production and extraction of vanadium-titanium

[0003] Adding a certain proportion of ordinary iron fine powder to the batching process before sintering sintering of vanadium-titanium fine powder has a series of positive effects on the three major processes of sintering, blast furnace and steelmaking, but vanadium-titanium fine powder and ordinary iron fine powder cannot To identify from the appearance, it is necessary to provide a precise mixing system and method for vanadium-titanium and ordinary iron fine powder to ensure that the mixing error of vanadium-titanium iron fine powder and ordinary iron fine powder is less than 1% in the actual production process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0052] The perfection of the automatic application control program of vanadium-titanium-ferrous fine powder. The PLC internal regulator is a PID regulator, and the PID regulator is a

[0053] batching process out-of-tolerance error correction and alarm. In the process of developing ingredients, the actual quality exceeds the theoretical quality by more than 1%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

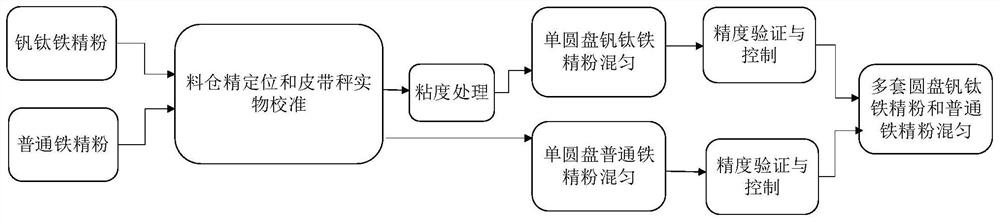

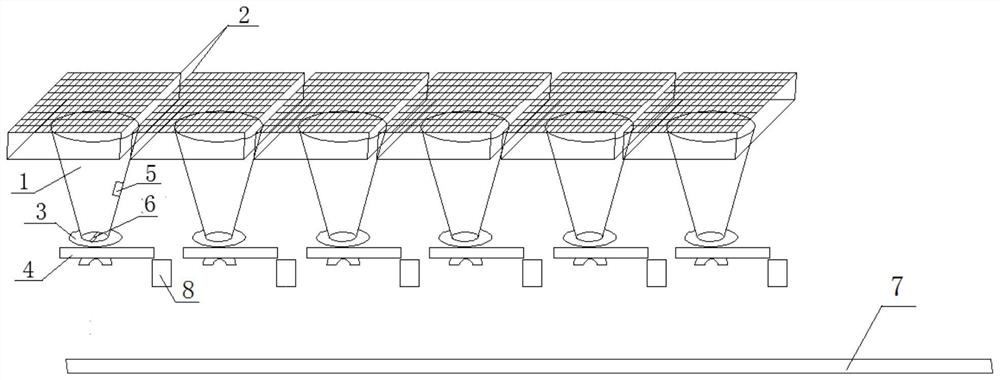

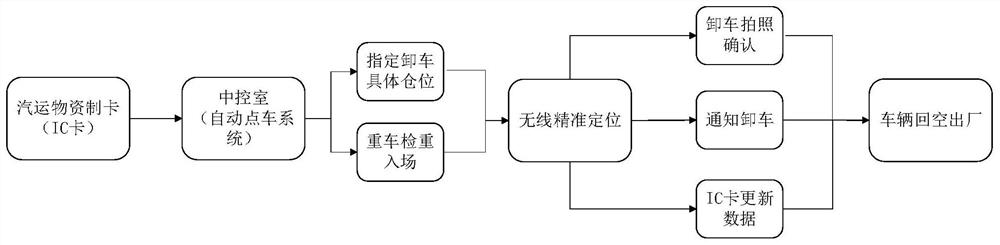

The invention relates to a precise mixing system and method for vanadium-titanium and common iron fine powder. The method is to precisely position the bins of the vanadium-titanium iron fine powder and the common iron fine powder, and to calibrate the weighing devices of the two materials in kind; Pretreat the vanadium-titanium-iron fine powder to ensure the loose uniformity of the vanadium-titanium-iron fine powder; accurately weigh and mix the common vanadium-titanium-iron fine powder and the pretreated vanadium-titanium iron fine powder; The mixing accuracy of the two kinds of iron concentrates is verified and controlled separately; while outputting each added single iron powder in sequence, the overall mixing output of multiple vanadium-titanium iron concentrates and ordinary iron concentrates is completed. The invention can precisely mix the two materials, improve the overall physical and chemical properties of vanadium-titanium sinter, reduce the return rate, increase the output and weight of vanadium-titanium sinter, fundamentally improve the flow performance of blast furnace molten iron, and finally realize converter steelmaking Smooth production and low-cost extraction of two precious metals, vanadium and titanium.

Description

A system and method for precise mixing of vanadium-titanium and ordinary iron fine powder technical field This patent application belongs to the comprehensive application technical field of vanadium-titanium magnetite, more specifically, relates to a kind of vanadium-titanium and A system and method for precise mixing of ordinary iron powder. Background technique Vanadium and titanium mainly exist in the vanadium-titanium magnetite in nature, and the main method of extraction is the steel-making converter extraction method, and two Elements play a huge role in steel, chemistry, aerospace, defense and other fields. my country's vanadium titanomagnetite is mainly distributed in Panxi (four Sichuan Panzhihua-Xichang) and Chengde area of Hebei Province. Sintering of vanadium titanomagnetite directly produced by crushed vanadium-titanium-iron powder The large fluctuation range of ore chemical properties, low drum index, and high ore return rate have plagued the high-w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01F23/60B01F33/80B01F35/71B01F35/80B01F35/21B01F35/22B01F23/70C22B34/12C22B34/22B01F101/45

CPCC22B34/22C22B34/12B01F23/69B01F23/70B01F33/80B01F35/20B01F35/714B01F35/71B01F35/881Y02P10/20

Inventor 朱佳利王锋范立志王刚闫金龙李立芬

Owner HEBEI IRON AND STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com