Method for designing femoral stem prosthesis

A design method and femoral stem technology, applied in prosthesis, femoral head, calculation, etc., can solve the problems of difficult customization of manufacturing process, complex internal structure manufacturing requirements, and large gap in femoral elastic modulus, so as to avoid stress concentration and stress shielding effects, improving implant compatibility, and reducing strain energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

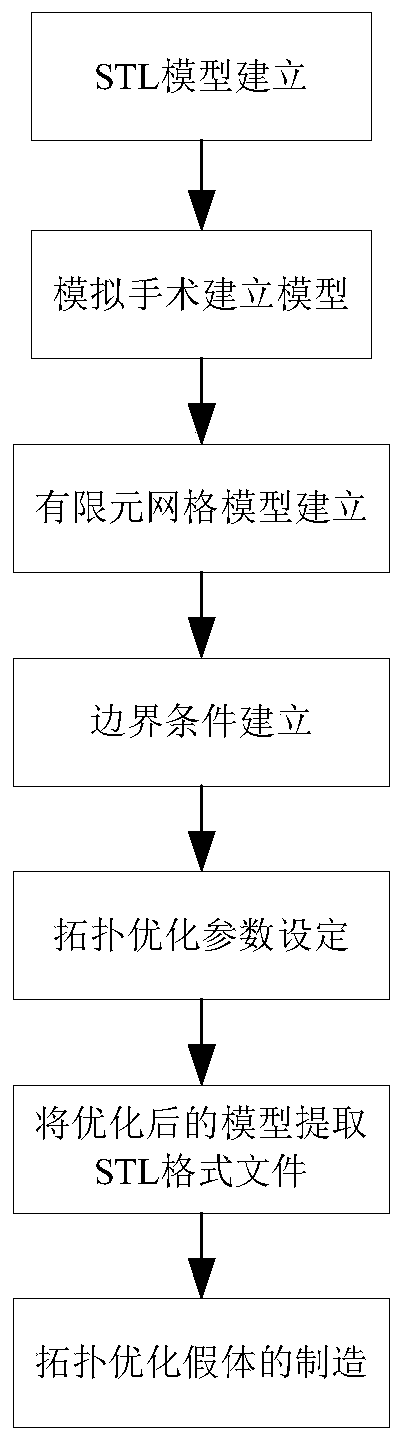

[0025] Specific implementation mode 1. Combination Figure 1 to Figure 6 Illustrate this embodiment, a kind of design method of novel femoral stem prosthesis, specifically:

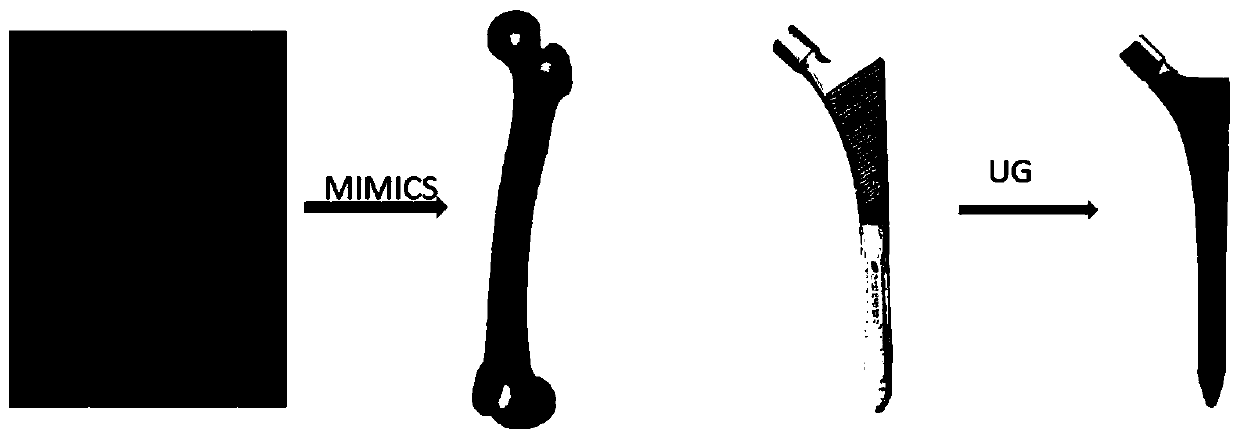

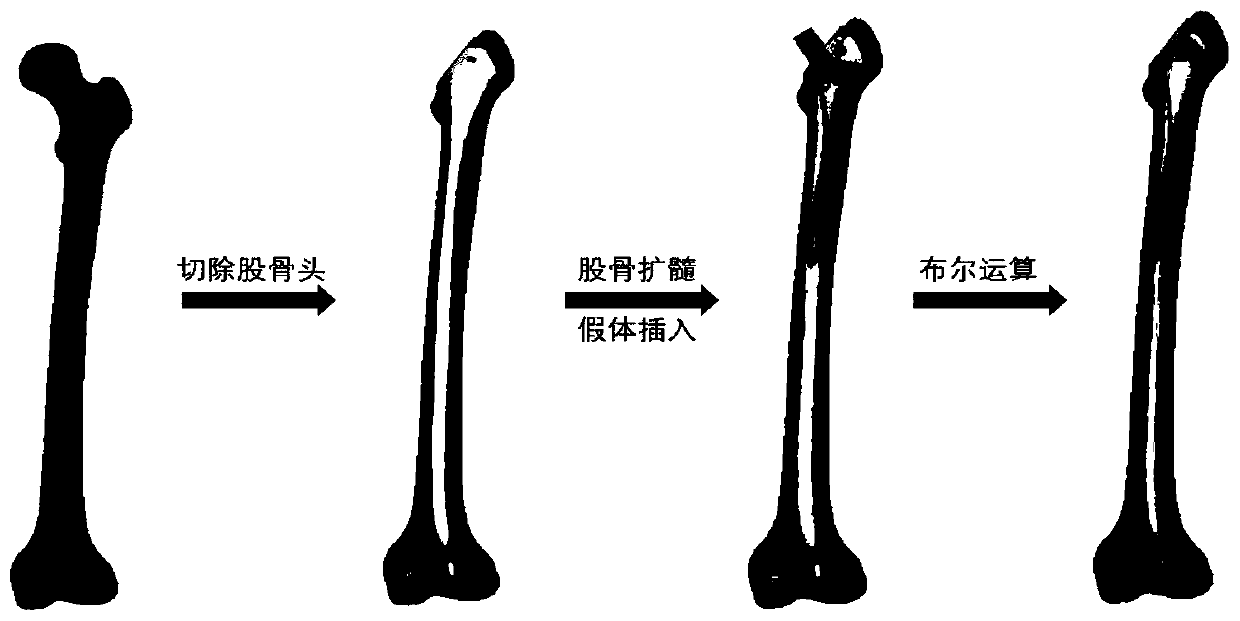

[0026] 1. STL model establishment. combine figure 2 , on the basis of the structure of the Synergy Porous hip joint prosthesis handle, UG software is used to draw the prosthesis in the sketch, and then complete the preliminary model establishment through operations such as cylinder and cone stretching and rotation. The prism of the prosthesis was rounded to prevent the prism from damaging the bone marrow cavity, and the three-dimensional model of the Synergy porous prosthesis was completed. Another volunteer with a height of 178cm and a weight of 70kg was selected for CT scan of the femur. According to the CT data, the threshold segmentation (Thresholding) function of Mimics software was used to select the bone threshold setting (range 326-3071HU) and threshold growth segmentation (Region Growing) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com