Antibacterial and disinfectant ultra-soft floor wet wipe and preparation method thereof

A technology of wet wipes and flooring, which is applied in the direction of botany equipment and methods, biocides, disinfectants, etc., can solve the problems of poor antibacterial and antivirus effects, low toxicity, and poor flexibility of floor wipes, and achieve good flexibility, Good permeability, good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

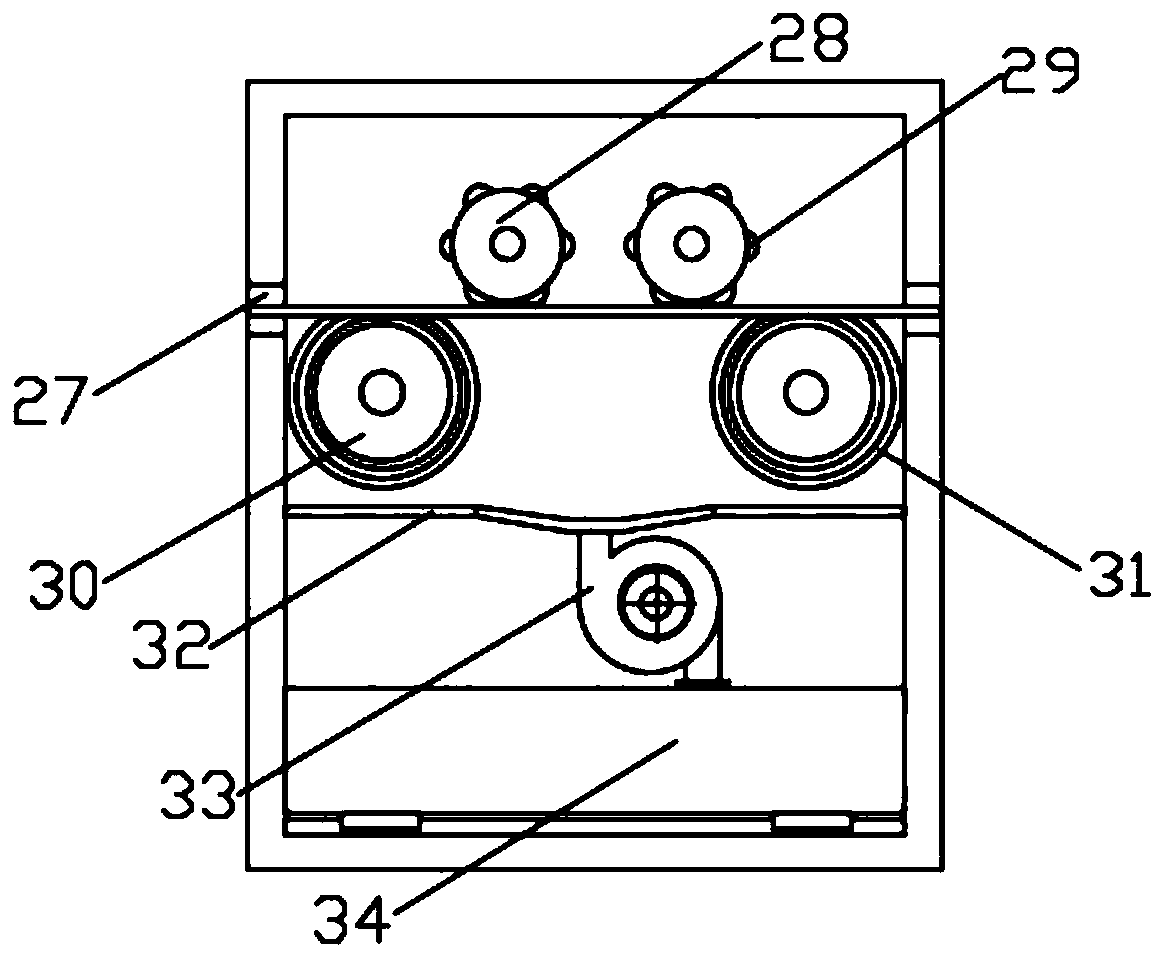

Image

Examples

Embodiment 1

[0034] An antibacterial and antivirus ultra-soft floor wet wipe is prepared by uniformly spraying an antibacterial and antivirus solution on a supersoft non-woven fabric. The antibacterial and antivirus solution is prepared from the following raw materials in parts by weight: cetylpyridinium chloride 5 parts, 30 parts of phenoxyethanol, 30 parts of glycerin, 10 parts of benzalkonium chloride, 6 parts of chamomile extract, 10 parts of olive oil, 0.5 parts of citric acid, and 100 parts of deionized water; Raw materials prepared in parts by weight: 15 parts of chitosan fiber, 30 parts of polypropylene, 20 parts of polyamide, 50 parts of polypropylene fiber, 35 parts of bamboo pulp fiber;

[0035] Wherein, the antibacterial and antivirus supersoft floor wet wipes are prepared through the following steps:

[0036] Step 1: Take cetylpyridinium chloride, phenoxyethanol, glycerin, benzalkonium chloride, chamomile extract, olive oil, citric acid, and deionized water according to the ab...

Embodiment 2

[0043] An antibacterial and antivirus ultra-soft floor wet wipe is prepared by uniformly spraying an antibacterial and antivirus solution on a supersoft non-woven fabric. The antibacterial and antivirus solution is prepared from the following raw materials in parts by weight: cetylpyridinium chloride 10 parts, 40 parts of phenoxyethanol, 35 parts of glycerin, 18 parts of benzalkonium chloride, 11 parts of chamomile extract, 16 parts of olive oil, 0.8 parts of citric acid, and 150 parts of deionized water; Raw materials were prepared in parts by weight: 20 parts of chitosan fiber, 35 parts of polypropylene, 30 parts of polyamide, 60 parts of polypropylene fiber, 45 parts of bamboo pulp fiber, and the rest of the steps were the same as in Example 1.

[0044] Specifically, in step two (3), the hot rolling temperature is 120° C., and the hot rolling pressure is 1.5 Mpa. The four spunlace pressures in Step 3 are 80bar, 120bar, 140bar, and 120bar respectively. The drying temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com