Purple sweet potato-tomato noodles and processing method thereof

A technology of tomato noodles and purple sweet potatoes, which is applied in food science, food preservation, food ingredients as taste improvers, etc., can solve the problems of reduced palatability of tomato sauce, high sugar content and low protein content of purple sweet potato noodles, and achieve Increase nutritional value and health function, rich dietary fiber, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

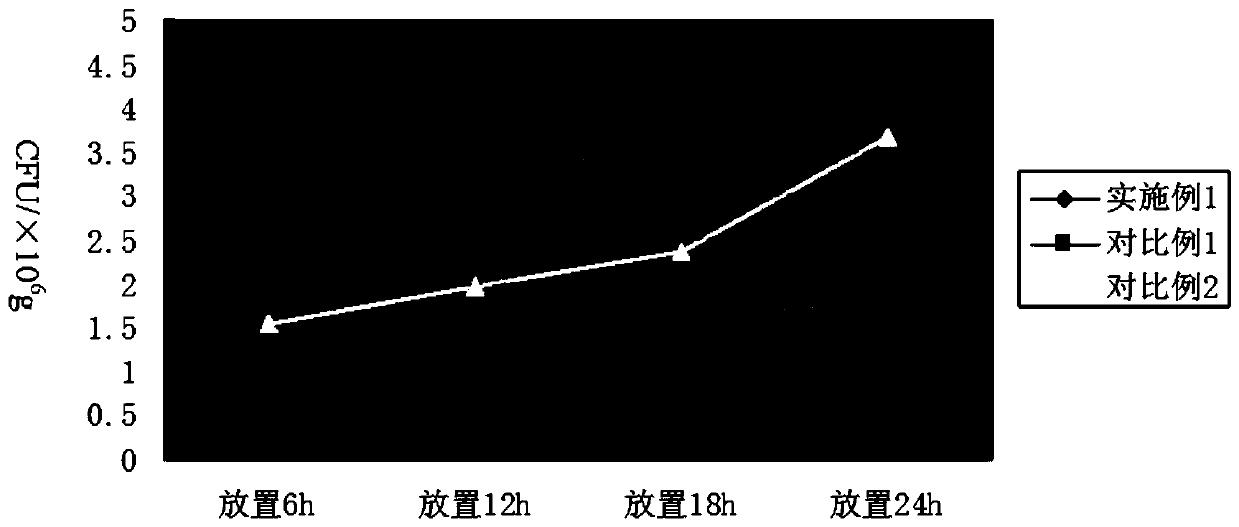

Examples

Embodiment 1

[0031] A Purple Potato Tomato Noodle

[0032] (1) Pre-mixing: Weigh 47kg of high-gluten wheat flour, 14kg of purple sweet potato flour, and 5kg of gluten powder in a vacuum dough mixer, and mix them at high speed for 2.5 minutes to obtain the mixed materials for later use;

[0033] (2) Kneading noodles: add 14kg of tomato paste to the mixture, add 20kg of salt water into the mixture through the spray pipe under high-speed operation, first stir at high speed for 7 minutes, then stir at low speed for 5.5 minutes until the dough becomes tofu residue shape, get the dough for later use;

[0034] (3) Composite calendering: the dough enters the compound machine and is calendered into 22mm dough pieces, which are then compounded together, and rolled into 0.9mm thick dough strips by 9 rollers, and the dough strips are ready for use;

[0035] (4) Cut into strips: Cut the noodle strips into noodles with a width of 3mm and a thickness of 0.9mm for later use;

[0036] (5) Low-temperature...

Embodiment 2

[0039] A Purple Potato Tomato Noodle

[0040] (1) Pre-mixing: Weigh 47kg of high-gluten wheat flour, 14kg of purple sweet potato flour, and 5kg of gluten powder, fully mix them in a vacuum dough mixer, stir at high speed for 2 minutes, and obtain the mixed materials for later use;

[0041] (2) Kneading noodles: add 14kg of tomato paste to the mixture, add 20kg of salt water into the mixture through the spray pipe under high-speed operation, first stir at high speed for 6 minutes, then stir at low speed for 5 minutes until the dough becomes tofu shape, get the dough for later use;

[0042] (3) Composite calendering: the dough enters the compound machine and is calendered into 20mm dough sheets, which are then compounded together, rolled by 9 rollers to form a dough strip with a thickness of 0.8mm, and the dough strips are ready for use;

[0043] (4) Cut into strips: Cut the noodle strips into noodles with a width of 3mm and a thickness of 0.9mm for later use;

[0044](5) Low-...

Embodiment 3

[0047] A Purple Potato Tomato Noodle

[0048] (1) Pre-mixing: Weigh 50kg of high-gluten wheat flour, 16kg of purple sweet potato flour, and 7kg of gluten powder in a vacuum dough mixer, and mix them at high speed for 3 minutes to obtain the mixed materials for later use;

[0049] (2) Kneading noodles: add 16kg of tomato paste to the mixture, add 22kg of salt water into the mixture through the spray pipe under high-speed operation, first stir at high speed for 8 minutes, then stir at low speed for 6 minutes until the dough becomes tofu residue shape, get the dough for later use;

[0050] (3) Composite calendering: the dough enters the compound machine and is calendered into 25mm dough sheets, which are then compounded together, and rolled into 1.0mm thick dough strips by 9 rollers, and the dough strips are ready for use;

[0051] (4) Cut into strips: Cut the noodle strips into noodles with a width of 3mm and a thickness of 0.9mm for later use;

[0052] (5) Low-temperature dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com