Automobile coating pretreatment and electrophoresis conveying device and conveying mode

A technology of conveying equipment and conveying methods, which is applied in the direction of conveyors, conveying objects, mechanical conveyors, etc., can solve the problems of troublesome chain maintenance of accumulation and storage circulation lines, single equipment conveying methods, poor stability of self-propelled trolleys, etc., and achieve automatic transfer Easy to hang, improve flexibility, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

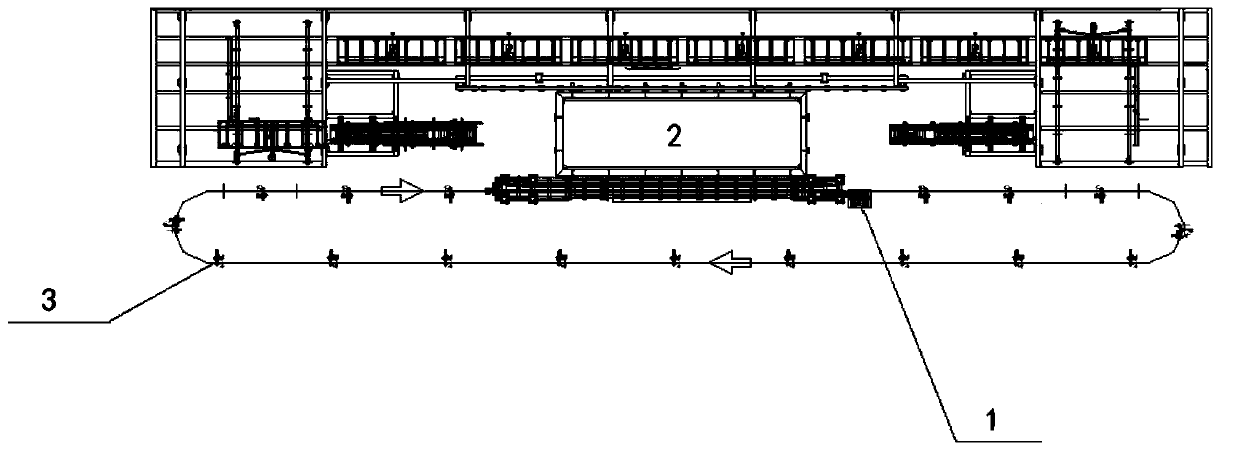

[0054] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

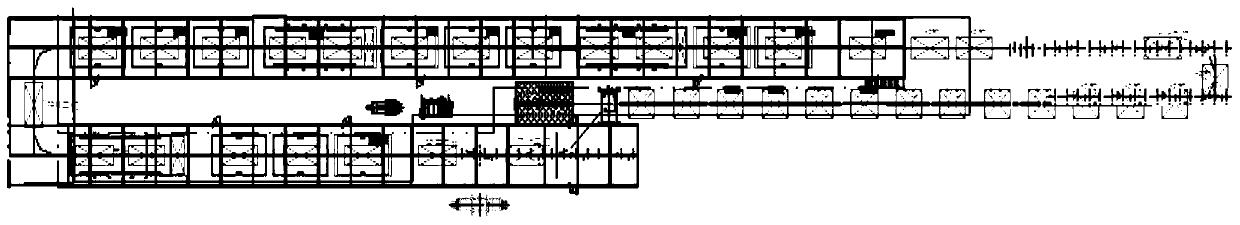

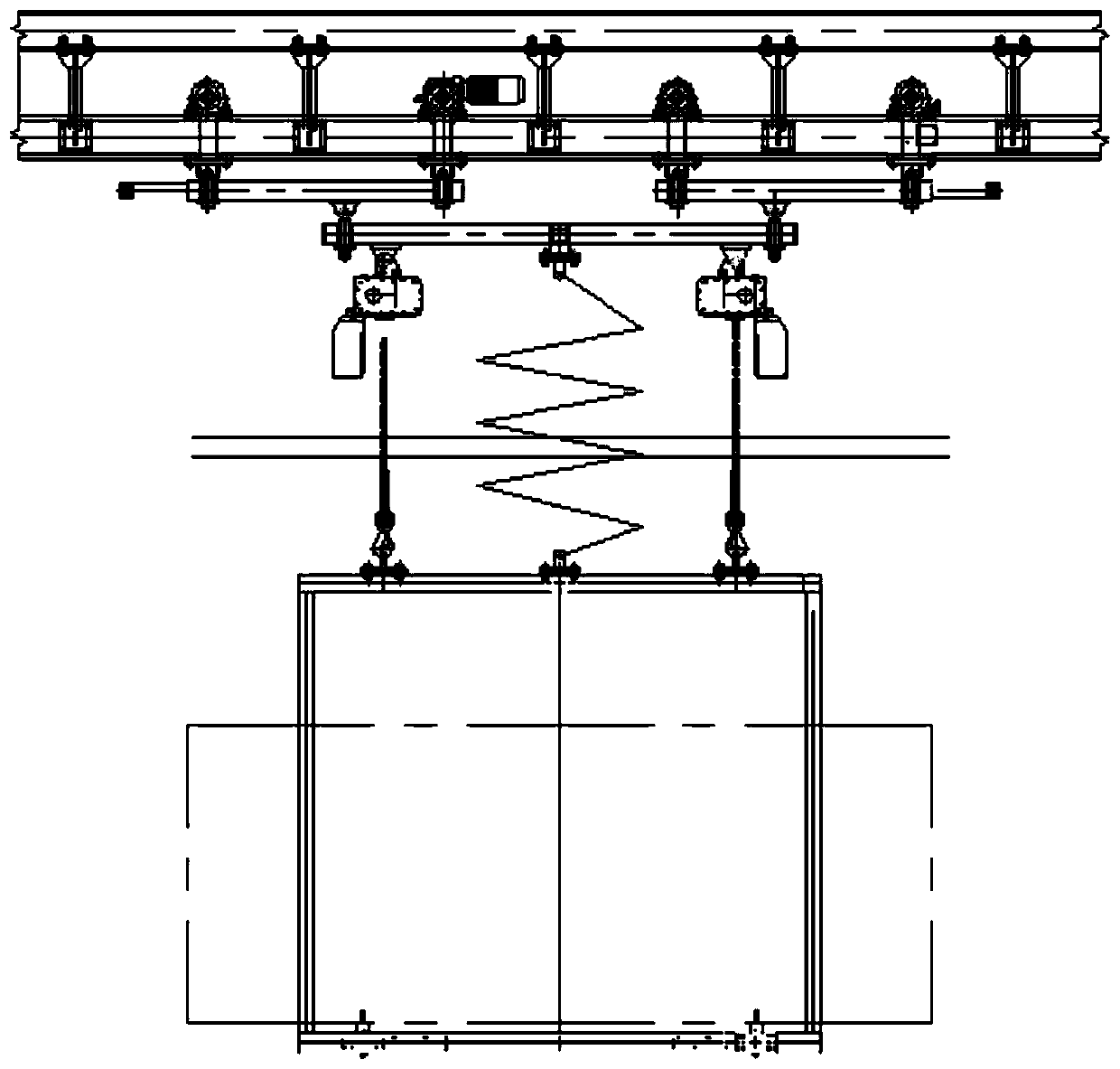

[0055] In the prior art, refer to figure 1 with figure 2 as shown, figure 1 It is a schematic diagram of the circulation line of the product and release chain in the prior art, figure 2 It is a schematic diagram of a gourd spreader in the prior art. The problems existing in the prior art include: poor stability of the self-propelled trolley equipment, movement of the gourd spreader both front and back, up and down, difficulty in automatic transfer, and poor stability; figure 1 The maintenance of the circulation line of the accumulation and release chain is troublesome, the noise is loud, and oil leakage is frequent, etc.;

[0056] In the prior art, the conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com