Porous layered carbon nitride/graphene/nickel disulfide super capacitor material and preparation method thereof

A supercapacitor and nickel disulfide technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of structural stability, poor cycle life, and poor electron mobility, and achieve good uniformity, high specific surface area utilization, and high ratio energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

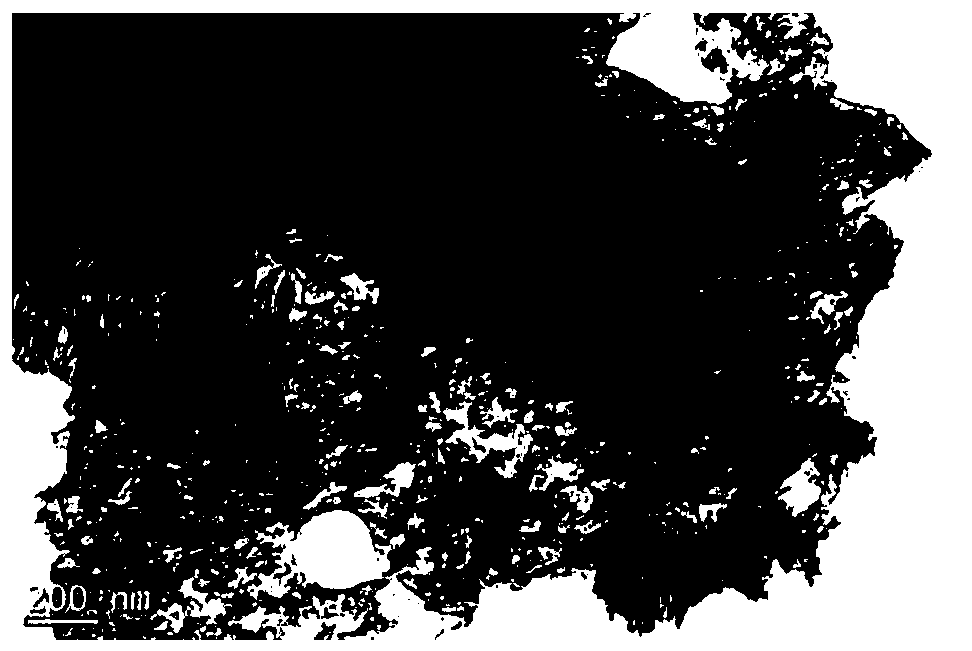

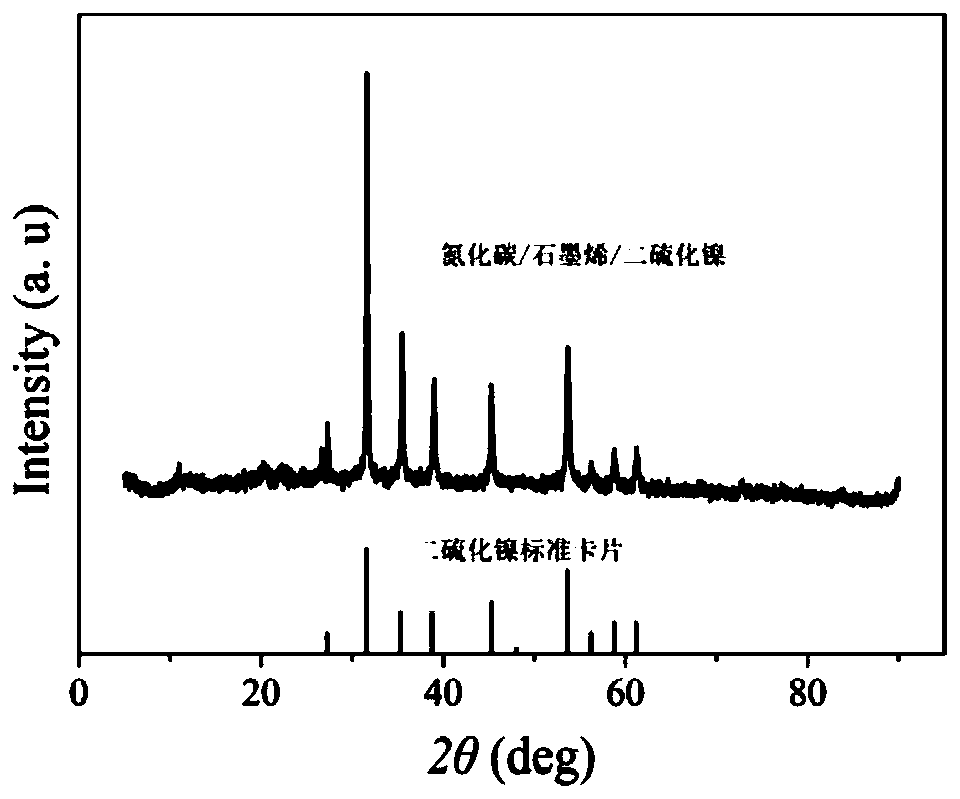

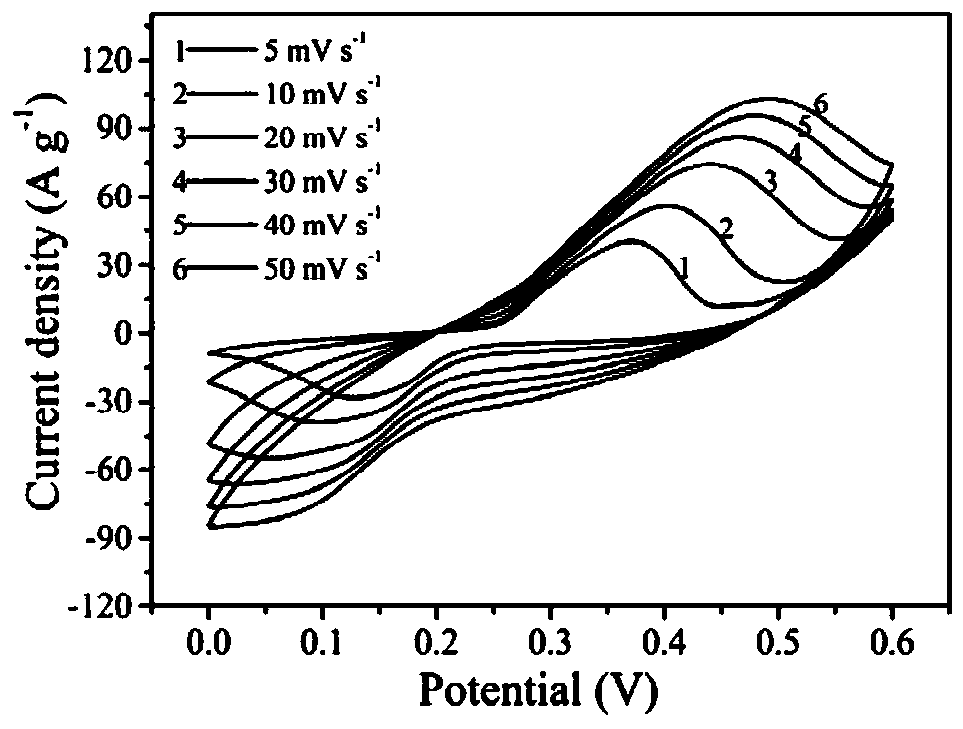

[0034] Disperse 0.5mmol of cellulose powder in N,N-dimethylacetamide solvent, add 5mmol of succinic anhydride, stir and react at 80°C for a period of time, then add 40mL of 2mg / mL graphene N,N-di The methylformamide dispersion is stirred at room temperature for a period of time, filtered, washed and then dispersed in water to obtain a modified cellulose-modified graphene aqueous solution. Dissolve 1 g of melamine in an acidic aqueous solution with a pH of 1, stir for 30 minutes, add 20 mg of modified cellulose-modified graphene dispersed in water, stir evenly, dry, and then calcinate at 550°C for 4 hours to obtain g-C 3 N 4 / graphene composites. Take 30mg of g-C 3 N 4 / Graphene was first ultrasonicated in N,N-dimethylformamide solution at a power of 250W for 2h, then filtered, washed, and then dispersed in 15mL aqueous solution, followed by adding 15mL of 0.6mmol nickel nitrate and 3mmol thiourea in ethyl alcohol The diol solution was added dropwise to the above solution,...

Embodiment 2

[0042] Disperse 0.5mmol cellulose powder in N,N-dimethylacetamide solvent, add 4mmol citric acid, stir and react at 80°C for a period of time, then add 80mL 0.5mg / mL graphene N,N-di The methylformamide dispersion is stirred at room temperature for a period of time, filtered, washed and then dispersed in water to obtain a modified cellulose-modified graphene aqueous solution. Dissolve 0.2g of melamine in an acidic solution with a pH of 2, stir for 30 minutes, add 20mg of modified cellulose-modified graphene dispersed in water, stir evenly, dry, and then calcinate at 500°C for 6h to obtain g-C 3 N 4 / graphene composites. 15mg g-C 3 N 4 / Graphene was first ultrasonicated in N,N-dimethylformamide solution at 250W power for 4h, then filtered, washed, and then dispersed in 30mL water, followed by ethylene glycol solution with 0.6mmol nickel nitrate and 3mmol thiourea Mix well, and transfer the formed mixture to a 50mL polytetrafluoroethylene reactor, and react at 170°C for 12...

Embodiment 3

[0044] Disperse 0.5mmol of cellulose powder in N,N-dimethylacetamide solvent, add 1mmol of thioglycolic acid, stir and react at 80°C for a period of time, then add 12mL of 2mg / mL graphene N,N-di The methylformamide dispersion is stirred at room temperature for a period of time, filtered, washed and then dispersed in water to obtain a modified cellulose-modified graphene aqueous solution. Dissolve 2 g of melamine in an acidic solution with a pH of 3, stir for 30 minutes, add 20 mg of modified cellulose-modified graphene dispersed in water, stir evenly, dry, and then calcinate at 580°C for 3 hours to obtain g-C 3 N 4 / graphene composites. Take 40mg g-C 3 N 4 / Graphene is first ultrasonicated for 0.5h under the power of N,N-dimethylformamide 250W, then filtered, washed, then dispersed in 8mL water, and then mixed with ethylene glycol solution of 0.6mmol nickel nitrate and 3mmol thiourea , Transfer the resulting mixed solution to a 50mL polytetrafluoroethylene reactor, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com