A kind of preparation method of mildew-proof and antibacterial latex paint

A technology of anti-mildew and antibacterial latex paint, applied in latex paint, antifouling/underwater paint, paint containing biocide, etc., can solve the problems of short sterilization time, poor compatibility and poor durability of latex paint, and achieve a combination The effect of enhancing the force, enhancing the binding force, and improving the utilization rate of the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

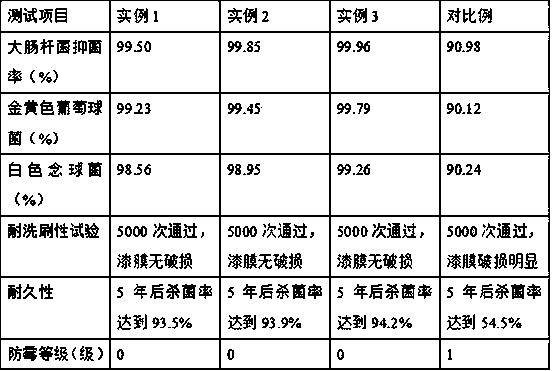

Examples

example 1

[0027]Be 1:10 by mass ratio konjac starch and the sodium silicate solution that mass fraction is 30% and mix to obtain mixed solution, be that 1mol / L hydrochloric acid is regulated mixed solution pH to 5.5 with concentration, stir reaction 20min to obtain pre-reaction liquid; The reaction solution was heated to 110°C, and the stirring reaction was continued for 1 hour to obtain a reaction solution, which was obtained by mixing a 10% sodium hydroxide solution with a mass fraction of 10% and a 20% lithium metaaluminate solution at a mass ratio of 1:2:10. Precursor solution: put the precursor solution into the high-pressure hydrothermal kettle, then add potassium thiocyanate with 2% of the mass of the precursor solution and 5% phenylalanine solution of the mass of the precursor solution to the high-pressure hydrothermal kettle, and seal the high-pressure hydrothermal kettle , heated to 200°C under 0.9MPa, and hydrothermally reacted for 20h; after the hydrothermal reaction was comp...

example 2

[0029] Be 1:10 by mass ratio konjac starch and the sodium silicate solution that mass fraction is 30% and mix to obtain mixed solution, be that 1mol / L hydrochloric acid is regulated mixed solution pH to 6.0 with concentration, stir reaction 25min to obtain pre-reaction liquid; Heat the reaction solution to 115°C, continue to stir and react for 1.5 hours to obtain a reaction solution, mix 10% sodium hydroxide solution with a mass fraction of 10% and lithium metaaluminate solution with a mass fraction of 20% at a mass ratio of 1:2:10 Obtain the precursor solution; put the precursor solution in the high-pressure hydrothermal kettle, then add potassium thiocyanate with 2% of the quality of the precursor solution and 5% of the phenylalanine solution of the quality of the precursor solution in the high-pressure hydrothermal kettle, and seal the high-pressure hydrothermal kettle, heated to 210°C under 1.0MPa, and hydrothermally reacted for 22 hours; after the hydrothermal reaction was...

example 3

[0031] Be 1:10 by mass ratio konjac starch and the sodium silicate solution that mass fraction is 30% mix to obtain mixed solution, be that 1mol / L hydrochloric acid is regulated mixed solution pH to 6.5 with concentration, stir reaction 30min to obtain pre-reaction liquid; The reaction solution was heated to 120°C, and continued to stir for 2 hours to obtain a reaction solution, which was obtained by mixing 10% sodium hydroxide solution with a mass fraction of 10% and a lithium metaaluminate solution with a mass fraction of 20% at a mass ratio of 1:2:10. Precursor solution: put the precursor solution into the high-pressure hydrothermal kettle, then add potassium thiocyanate with 2% of the mass of the precursor solution and 5% phenylalanine solution of the mass of the precursor solution to the high-pressure hydrothermal kettle, and seal the high-pressure hydrothermal kettle , heated to 220°C under 1.2MPa, and hydrothermally reacted for 24 hours; after the hydrothermal reaction w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com