Porous carbon nanobelt lithium-sulfur battery positive electrode material and its preparation method and application

A technology for lithium-sulfur batteries and positive electrode materials, applied in the field of porous carbon nanobelt lithium-sulfur battery positive electrode materials and its preparation, can solve the problem of unsatisfactory rate performance and cycle performance of carbon-containing lithium-sulfur battery positive electrode materials, lithium-sulfur battery rate performance and Poor cycle performance and other problems, to achieve good wettability and high elemental sulfur content, improve sulfur fixation performance, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] On the one hand, an embodiment of the present invention provides a method for preparing a porous carbon nanobelt lithium-sulfur battery positive electrode material. The preparation method of the porous carbon nanobelt lithium-sulfur battery cathode material comprises the following steps:

[0028] Step S01. Prepare carbon nanobelt precursor:

[0029] Formaldehyde and hydroquinone are hydrothermally reacted in an acidic solution to obtain a carbon nanobelt precursor;

[0030] Step S02. Carbonizing and activating the carbon nanobelt precursor:

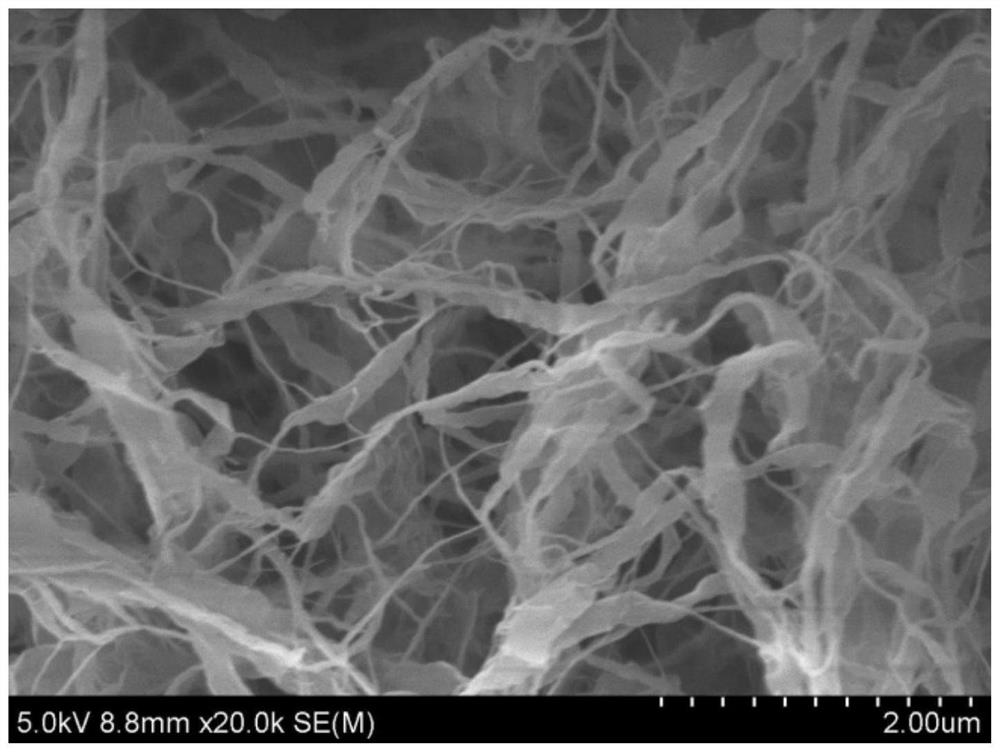

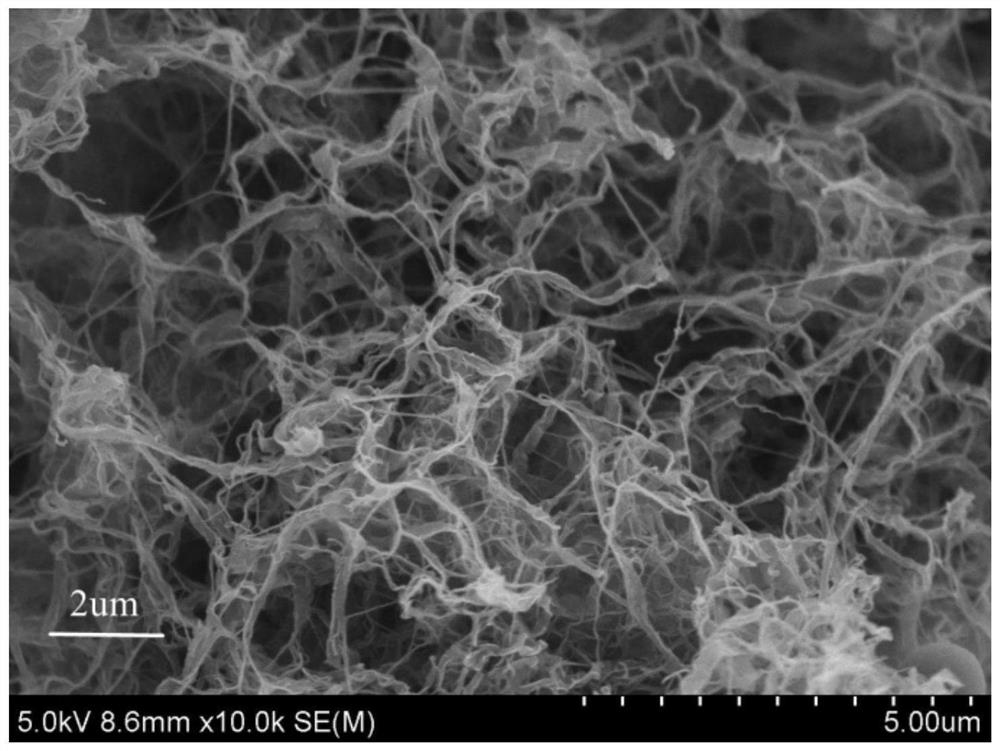

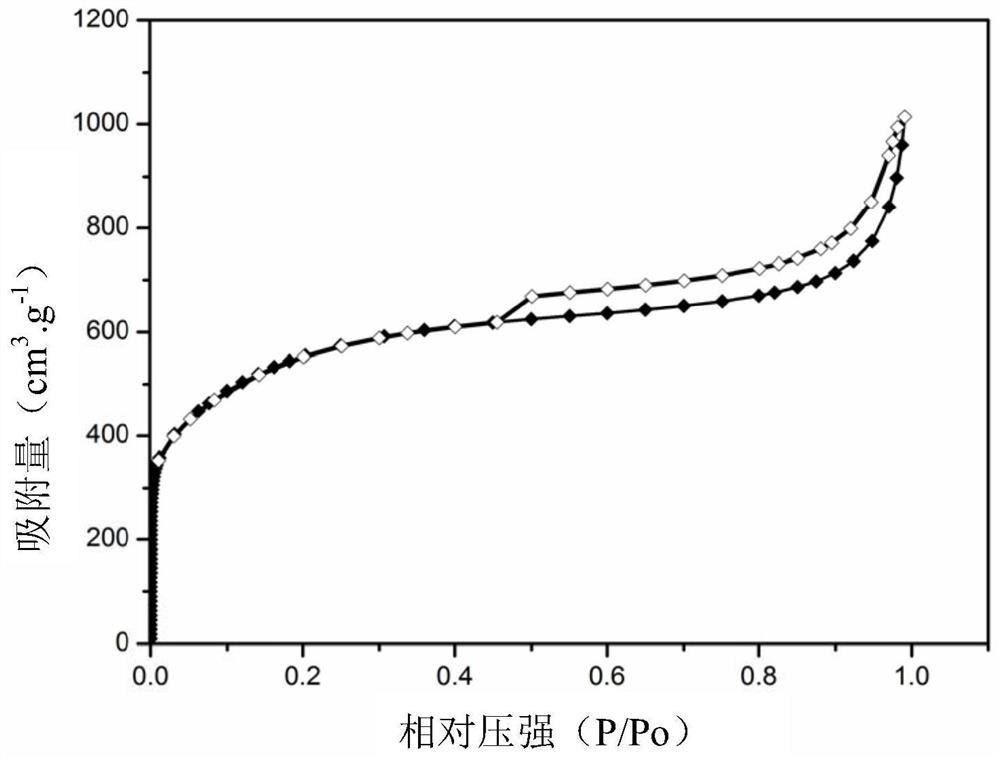

[0031] The carbon nanobelt precursor is subjected to carbonization treatment and ammonia water activation treatment to obtain nitrogen and oxygen co-doped porous carbon nanobelts;

[0032] Step S03. Depositing elemental sulfur in the nitrogen-oxygen co-doped porous carbon nanobelts:

[0033] After the nitrogen-oxygen co-doped porous carbon nanobelt is mixed with elemental sulfur, heat treatment is performed in a closed environme...

Embodiment 1

[0057] This embodiment provides a porous carbon nanobelt lithium-sulfur battery cathode material and a preparation method thereof. The method for preparing the positive electrode material of the porous carbon nanobelt lithium-sulfur battery comprises the following steps:

[0058] S11: Weigh 120g of 10% dilute hydrochloric acid, 2.5g of 37% formaldehyde solution, and 1.65g of hydroquinone, and stir the three for 30 minutes until a uniform and transparent solution is formed;

[0059] S12: Pour the solution prepared in the above steps into a polytetrafluoroethylene-lined hydrothermal reaction kettle, seal the hydrothermal kettle and put it in an oven at 180°C, react for 12 hours, and cool it down to room temperature naturally;

[0060] S13: Filter the product obtained in the above steps, wash it with deionized water for 5 times, then place it in a vacuum drying oven, and dry it at 60°C for 24 hours;

[0061] S14: Grinding the dried product (carbon nanobelt precursor) into powder...

Embodiment 2

[0066] This embodiment provides a porous carbon nanobelt lithium-sulfur battery cathode material and a preparation method thereof. The method for preparing the positive electrode material of the porous carbon nanobelt lithium-sulfur battery comprises the following steps:

[0067] S11: Weigh 125g of 10% dilute hydrochloric acid, 2.8g of 37% formaldehyde solution, and 1.5g of hydroquinone, and stir the three for 20 minutes;

[0068] S12: Pour the solution prepared in the above steps into a polytetrafluoroethylene-lined hydrothermal reaction kettle, seal the hydrothermal kettle and place it in an oven at 150°C, react for 15 hours, and naturally cool to room temperature;

[0069] S13: Filter the product obtained in the above steps, wash it with deionized water for 6 times, and then place it in a common drying oven and dry it at 80°C for 15 hours;

[0070] S14: Grinding the dried product (carbon nanobelt precursor) into powder, sealed and stored for later use;

[0071] S15: Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com