Roller way sintering furnace with uniform hearth temperature

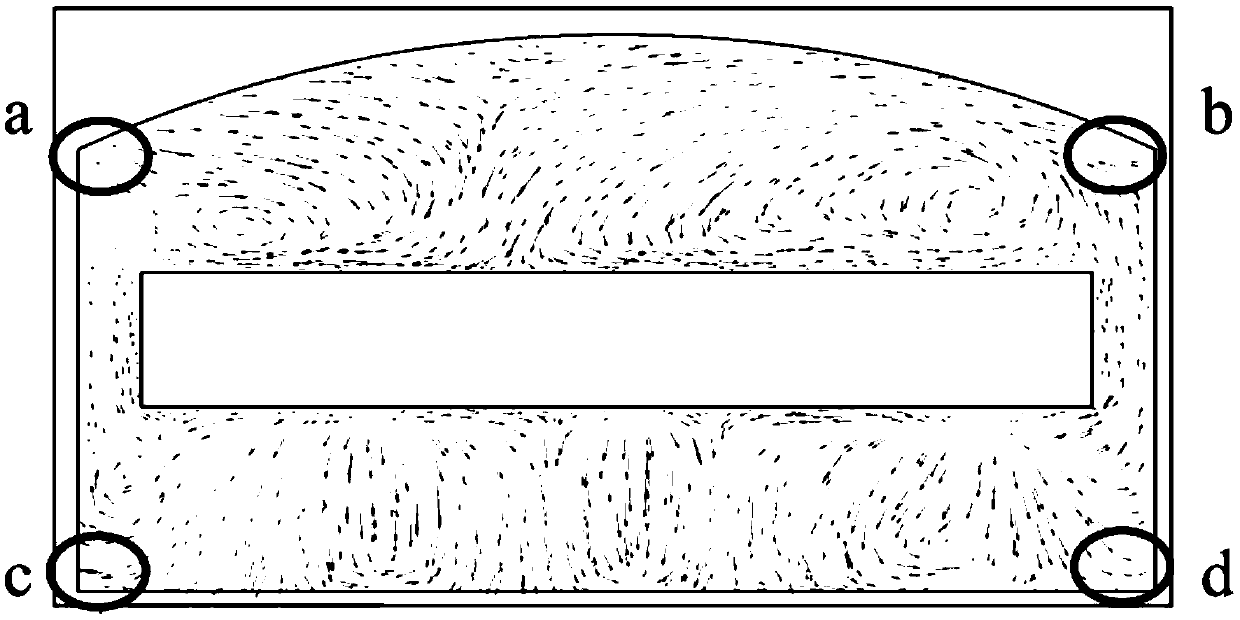

A furnace temperature and sintering furnace technology, which is applied in the field of industrial sintering equipment, can solve the problems that the uniformity of the temperature field of the furnace flow field is difficult to ensure, affects the flow of atmosphere gas in the furnace, and the uniformity of the furnace temperature decreases, so as to achieve good heat radiation ability, Reduce flow dead zone, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

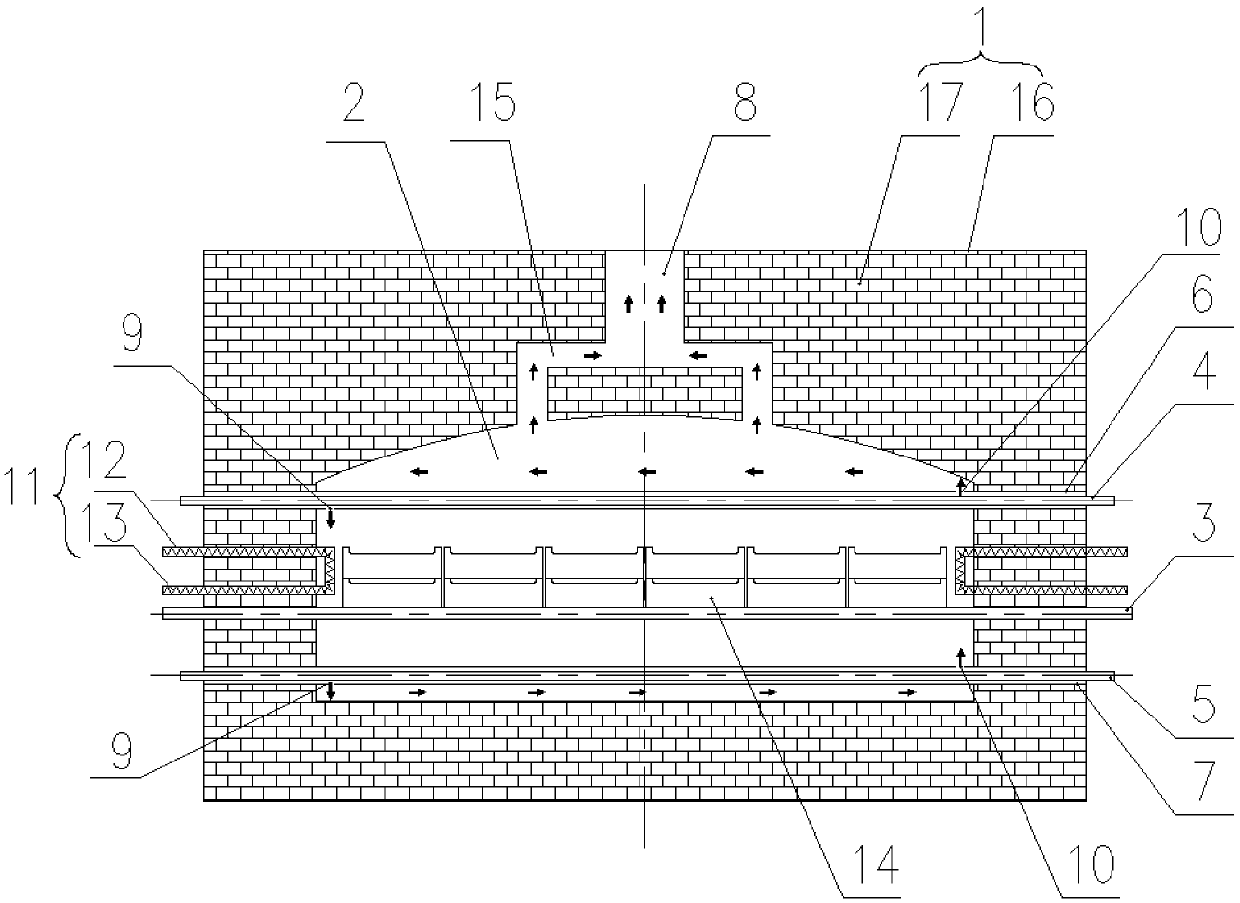

[0038] The roller sintering furnace with uniform furnace temperature of this embodiment is basically the same as that of Embodiment 1, the only difference being:

[0039] In this embodiment, the diameters of the first air inlet 9 and the second air inlet 10 are 32mm.

[0040] In the present embodiment, the diameter of the graphite protection tube 12 is 54mm, and the resistivity of the resistance wire ρ=1.4Ω·mm 2 m -1 , The diameter of the iron-chromium-aluminum alloy resistance wire 13 is 3mm.

Embodiment 3

[0042] The roller sintering furnace with uniform furnace temperature of this embodiment is basically the same as that of Embodiment 1, the only difference being:

[0043] In this embodiment, the diameters of the first air inlet 9 and the second air inlet 10 are 36mm.

[0044] In the present embodiment, the diameter of the graphite protection tube 12 is 60mm, and the resistivity of the resistance wire ρ=1.4Ω·mm 2 m -1 , The diameter of the iron-chromium-aluminum alloy resistance wire 13 is 3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com