Polyimide/carbon nano-tube (PI/CNT) electromagnetic shielding composite material with isolation structure

An isolation structure and electromagnetic shielding technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of loss of PLA's effective coating of CNT, inability to fully exert electromagnetic shielding performance, poor mechanical and heat resistance, etc., to achieve Enhanced electromagnetic shielding performance, easy implementation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1~15

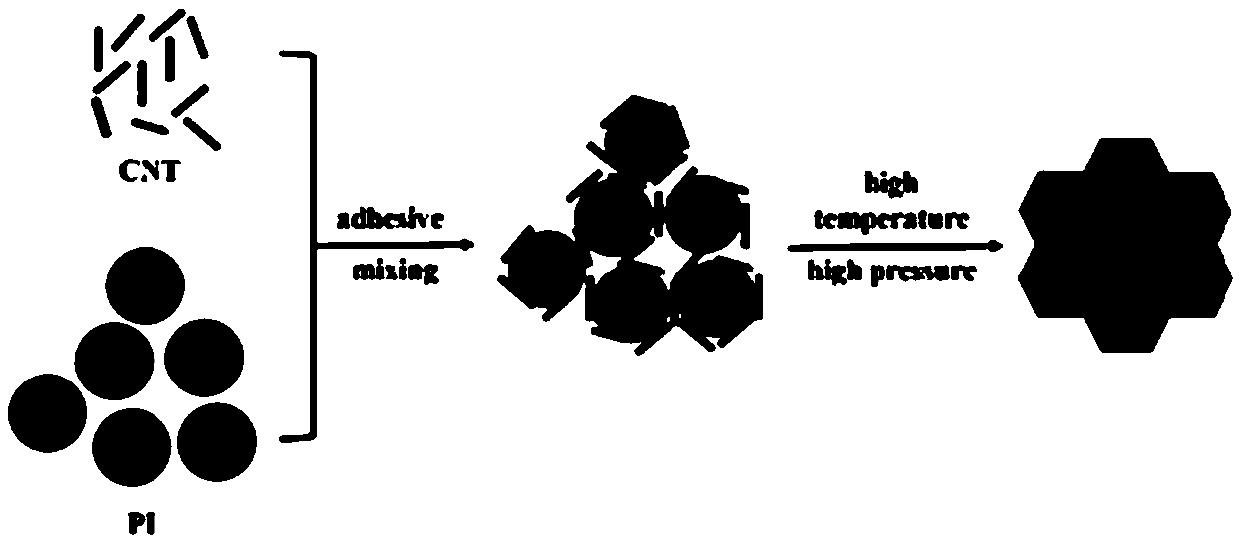

[0026] (1) Preparation of PI@CNT composite particles: At room temperature, PI particles (Ultem 1000, product of SABIC Innovative Plastics Co., Ltd.) with different particle sizes were used respectively, with the assistance of PI solution (DMAc solution of Ultem 1000), CNT (NC7000, product of Nanocyl Company in Belgium, taking CNT powder with an average size of 1.51 μm (length) and 9.5 nm (diameter) as an example) and PI matrix mass ratios are 0.5:99.5, 1:99, 3:97, respectively , 5:95, 7:93, corresponding to the added PI solution (taking the DMAc solution of PI with a solid content of 20wt% as an example) the mass parts are 4.0 parts, 9.9 parts, 15.4 parts, 19.7 parts, 25.5 parts respectively. First add PI solution to PI granules, then add CNT, add PI solution and CNT to PI granules in small amounts in small amounts, make sure to stir thoroughly after each addition, mix evenly, and cycle until CNT completely covers PI granules surface, and there is no obvious adhesion between p...

example 16~20

[0033](1) Preparation of PI@CNT composite particles: at room temperature, 93 parts of PI particles (Ultem 1000, product of SABIC Innovative Plastics Co., Ltd.) with an average particle size of 0.22 mm, CNT (NC7000, product of Nanocyl Company of Belgium, CNT powder with an average size of 1.51μm (length) and 9.5nm (diameter) as an example) 7 parts, respectively add PI solutions with different solid contents and different solvents (the DMAc solution of Ultem 1000 with a solid content of 15wt% and 25wt%, DMAc solution of Ultem 1000 with solid content of 15wt%, 20wt% and 25wt%) 34.0 parts, 20.4 parts, 34.0 parts, 25.5 parts, 20.4 parts. First add PI solution to the PI pellets, and then add CNT, add the PI solution and CNT to the PI pellets in small amounts in small amounts, make sure to stir thoroughly after each addition, mix evenly, and cycle until the CNTs completely cover the PI pellets surface, and there is no obvious adhesion between particles, and then use a blast oven to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com