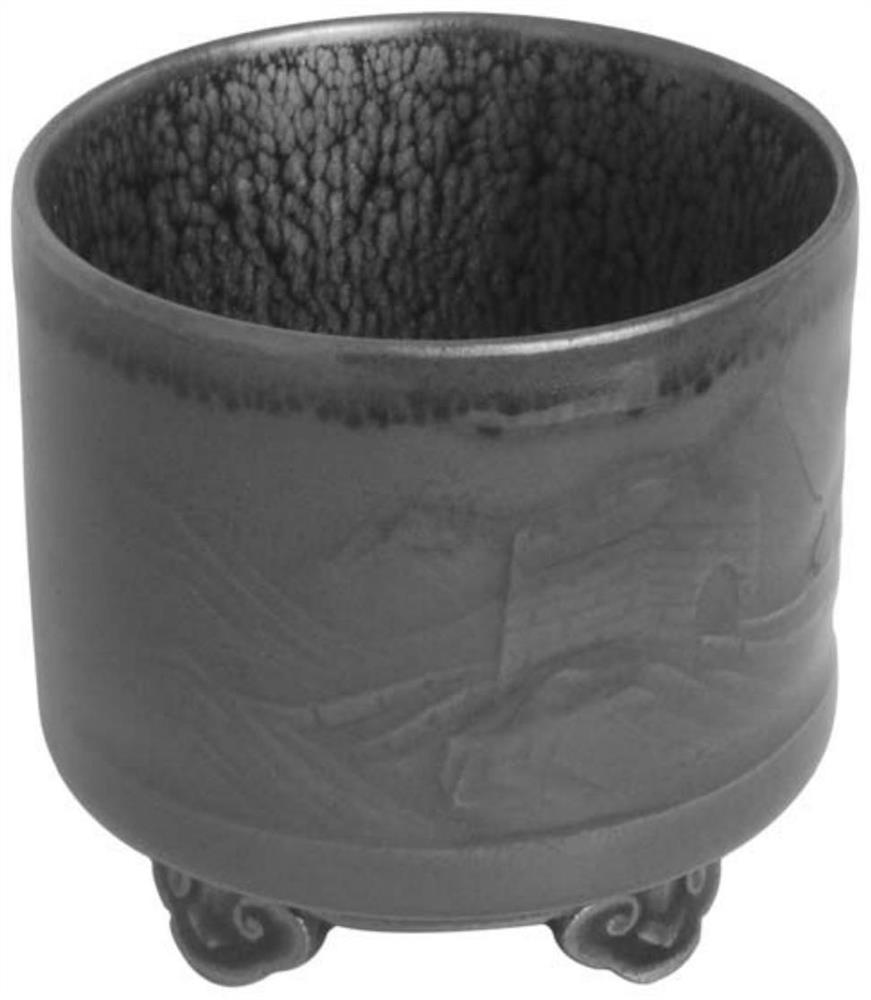

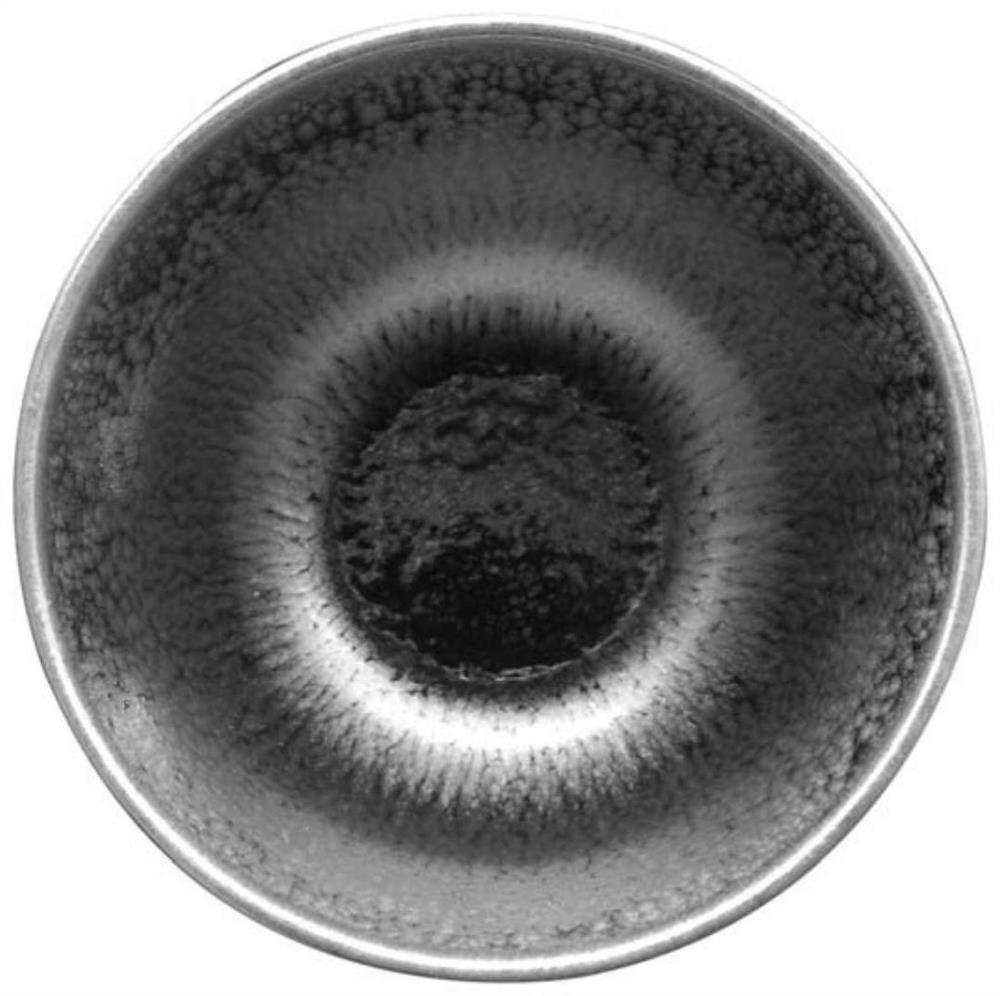

Porcelain firing process combining celadon and Jianzhan

A celadon and craft technology, applied in the production of clay products, drinking utensils, ceramic materials, etc., can solve problems such as difficult to combine, no porcelain is found, and achieve stable color, good flammability, and shiny and full oil droplets. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The porcelain firing process combining celadon and Jianzhan includes the following steps:

[0041] (1) Prepare green body raw materials, Jianzhan glaze slurry, celadon glaze slurry, wherein,

[0042] The green body raw material is prepared by the following method: mixing 7 parts by weight of kaolin, 1 part by weight of field mud and 3 parts by weight of red mud, crushing, elutriating, grinding, passing through a 90-mesh sieve, press filtration, mud refining, After aging for one year, the raw material of the green body is obtained;

[0043] The Jianzhan glaze slurry is prepared by the following method: mix 5 parts by weight of glaze ore, 3 parts by weight of plant ash, 2 parts by weight of field mud, and 0.3 parts by weight of iron red, add 3.5 times by weight of water and put it into a ball mill Grind and pass through a 90-mesh sieve to obtain Jianzhan glaze slurry;

[0044] The celadon glaze slurry is prepared by the following method: take 65 parts by weight of ridge...

Embodiment 2

[0062] The porcelain firing process combining celadon and Jianzhan includes the following steps:

[0063] (1) Prepare green body raw materials, Jianzhan glaze slurry, celadon glaze slurry, wherein,

[0064] The green body raw material is prepared by the following method: mixing 6 parts by weight of kaolin, 2 parts by weight of field mud and 4 parts by weight of red mud, crushing, elutriating, grinding, passing through a 80-mesh sieve, press filtration, mud refining, After aging for one year, the raw material of the green body is obtained;

[0065] The Jianzhan glaze slurry is prepared by the following method: mix 4 parts by weight of glaze ore, 3 parts by weight of plant ash, 2 parts by weight of field mud, and 0.3 parts by weight of iron red, add 3 times the weight of water and put it into a ball mill Grind and pass through an 80-mesh sieve to obtain Jianzhan glaze slurry;

[0066] The celadon glaze slurry is prepared by the following method: take 70 parts by weight of ridg...

Embodiment 3

[0082] The porcelain firing process combining celadon and Jianzhan includes the following steps:

[0083] (1) Prepare green body raw materials, Jianzhan glaze slurry, celadon glaze slurry, wherein,

[0084] The green body raw material is prepared by the following method: mixing 8 parts by weight of kaolin, 1 part by weight of field mud and 2 parts by weight of red mud, crushing, elutriating, grinding, passing through a 100-mesh sieve, pressure filtration, mud refining, After aging for one year, the raw material of the green body is obtained;

[0085] The Jianzhan glaze slurry is prepared by the following method: mix 6 parts by weight of glaze ore, 3.5 parts by weight of plant ash, 3 parts by weight of field mud, and 0.2 parts by weight of iron red, add 3 times by weight of water and put it into a ball mill Grind and pass through a 100-mesh sieve to obtain Jianzhan glaze slurry;

[0086] The celadon glaze slurry is prepared by the following method: take 60 parts by weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com