High-flux low-pressure composite reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane and high-flux technology, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of decreased desalination rate of low-pressure reverse osmosis membrane, increase flux of low-pressure reverse osmosis membrane, and poor desalination layer Resistance to pressure scouring and other issues, to achieve the effect of improving hydrophilicity, improving channel hydrophilicity, and increasing water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

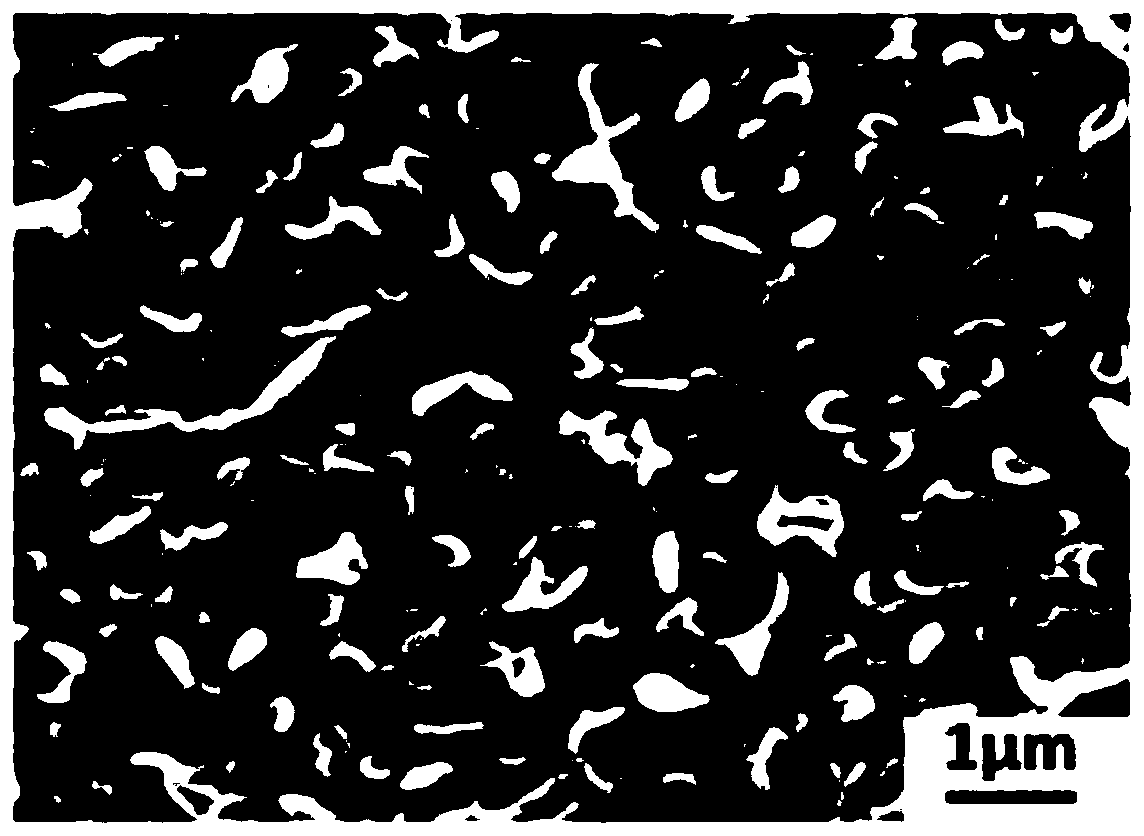

Image

Examples

Embodiment 1

[0029] A method for preparing a high-throughput low-pressure composite reverse osmosis membrane, comprising the steps of:

[0030] (1) Mix and dissolve 40g citric acid and 20g triethylamine evenly as a two-phase organic buffer, then add 20g m-phenylenediamine and 20g water phase modifier N,N dimethylformamide, deionized water Dilute to 1000g, stir evenly to obtain m-phenylenediamine aqueous phase solution, set aside;

[0031] (2) Dissolve 1g of trimesoyl chloride in an organic solvent, stir until evenly mixed, then add 1g of oil phase modifier isopropanol, add an organic solvent to dilute to 500g, stir and dissolve to obtain an organic oil phase of trimesoyl chloride Solution; Described organic solvent is that Isopar G and hexanaphthene are mixed by volume ratio 7:3;

[0032] (3) Cut the porous supporting layer of corresponding size, first soak in the m-phenylenediamine aqueous phase solution obtained in step (1) for 0.5-1min, drain the surface water drops, then soak in the h...

Embodiment 2~5

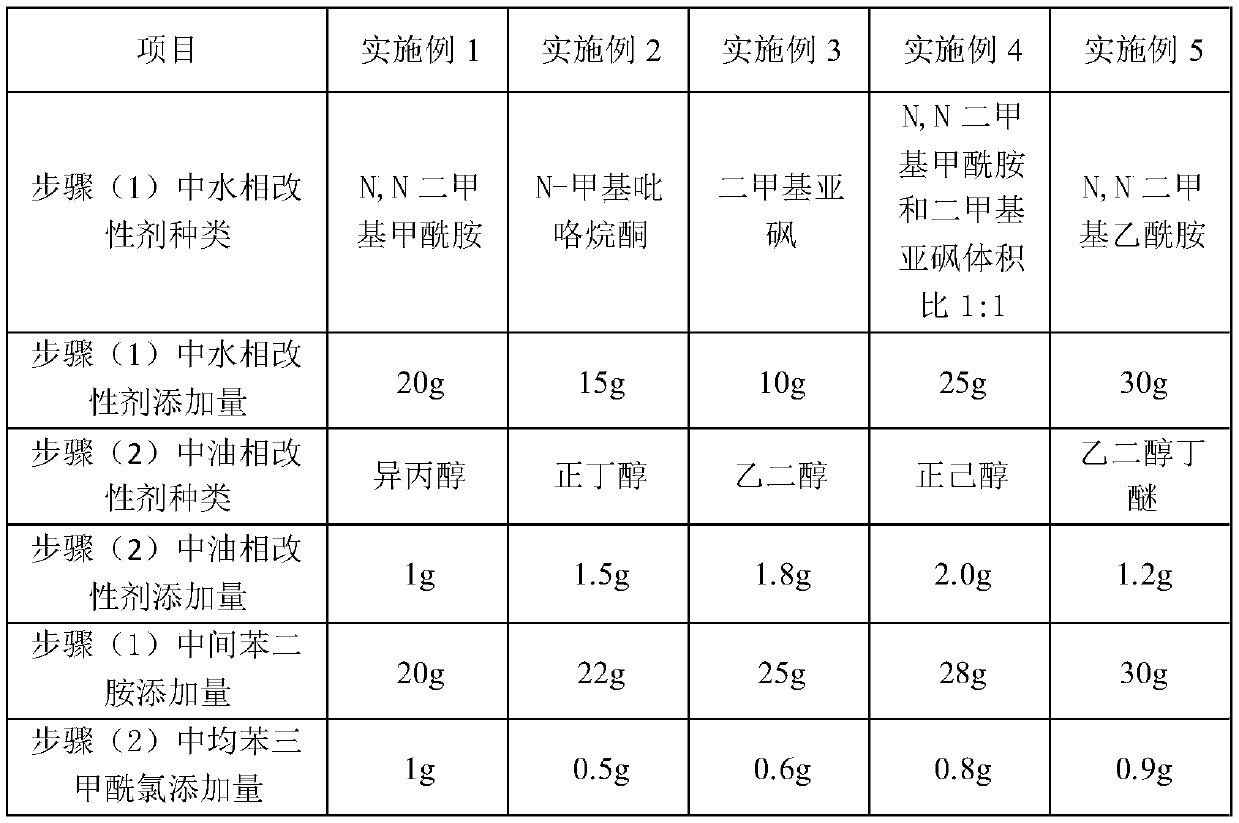

[0034] A preparation method of a high-flux low-pressure composite reverse osmosis membrane is basically the same as in Example 1, the differences are as shown in Table 1:

[0035] Table 1

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com