Flame-retardant epoxy putty, and preparation method and application thereof

A technology of epoxy putty and flame retardant, applied in the direction of filling slurry, etc., can solve the problem that the strength of the edge of the sandwich panel cannot be guaranteed, and achieve the effects of reducing salt spray corrosion, wide application range, and Tg increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

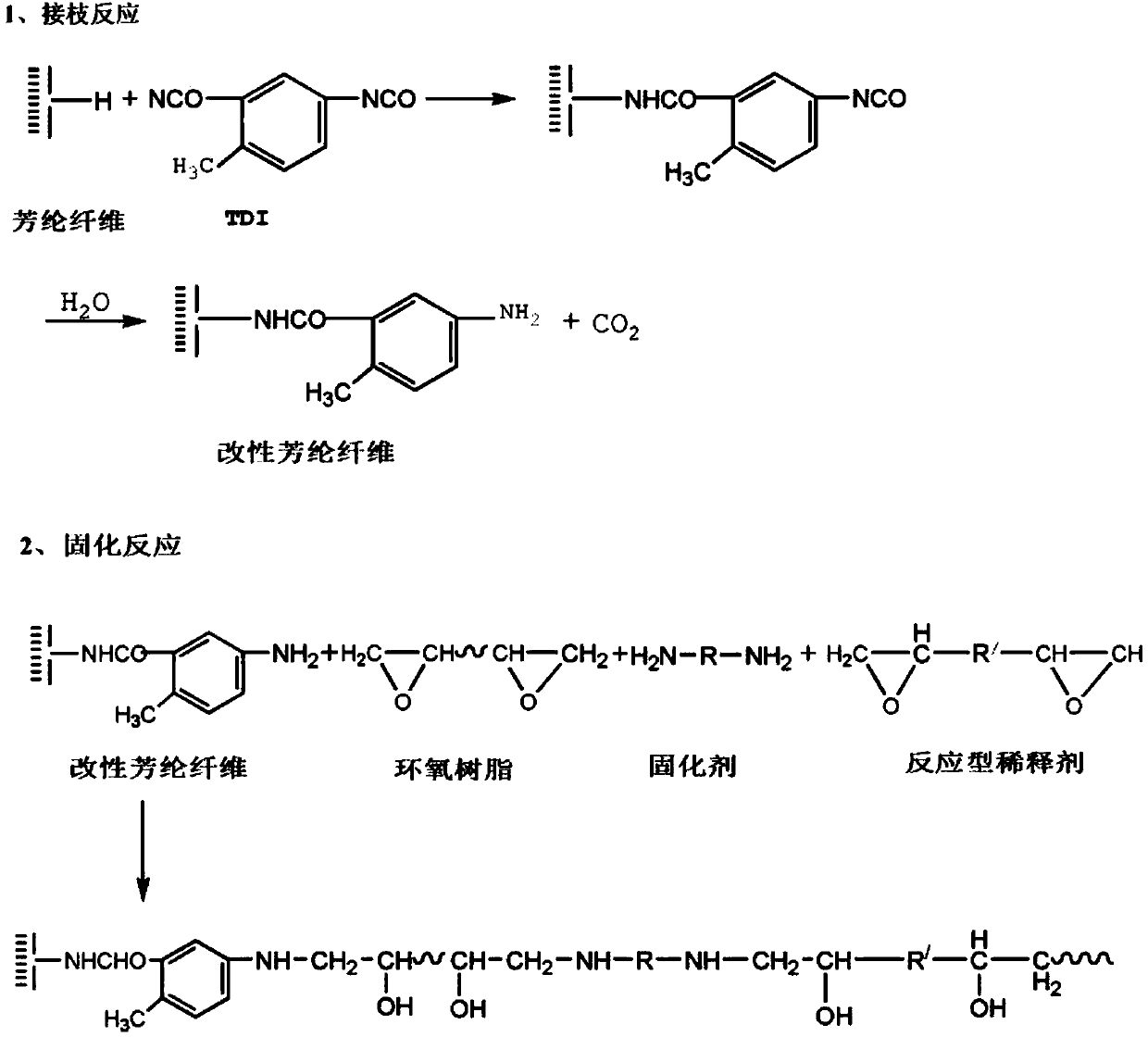

Method used

Image

Examples

preparation example Construction

[0046] In a preferred embodiment, the preparation method of flame retardant epoxy putty comprises the following steps:

[0047] (1) Preheat the epoxy resin to 60-80°C, add modified aramid chopped fiber, wetting dispersant, defoamer, and coupling agent to disperse evenly in the epoxy resin, and cool down to 15-30°C Obtain aramid fiber epoxy slurry A;

[0048] -NH on the coupling reagent 2 It will react with the -NCO group grafted on the surface of the aramid fiber to further enhance the compatibility of the fiber surface and improve the dispersion of other components.

[0049] (2) Evenly disperse the epoxy curing agent, flame retardant, and defoamer into the reactive diluent to obtain a uniform liquid component B;

[0050] (3) Mix the two components prepared in step (1) and step (2), add fillers, pigments, wetting and dispersing agents, and defoamers, and disperse evenly to obtain a flame-retardant epoxy putty.

Embodiment 1

[0052] (1) Prepare a 0.5% toluene diisocyanate aqueous solution, soak the aramid chopped fiber 1313 in the aqueous solution for 24 hours, then wash it repeatedly with distilled water, dry it for later use, and obtain the modified aramid chopped fiber 1313;

[0053] (2) Take 300g of DEN438 epoxy resin and 300g of MHR070 epoxy resin, mix and preheat to 65°C, use a disintegrator to disperse 50g of modified aramid chopped fiber 1313 into the epoxy resin solution, and add 5g of wetting and dispersing agent in turn 2070, 3g defoamer BYK023, 3g coupling agent KH792, after the dispersion is completed, cool down to 20°C to obtain aramid fiber epoxy slurry A;

[0054] (3) Take 50g of p-phenyl tert-butyl glycidyl ether, 10g of 1-cyanoethyl-2-ethyl-4-4 methylimidazole, 55g of dicyandiamide, 60g of triethyl phosphate, and 5g of KH792 are evenly dispersed to In the reactive diluent, component B is obtained;

[0055] (4) Mix the two components prepared in step (2) and step (3), and add 220g o...

Embodiment 2

[0058] (1) Prepare a 3% aqueous solution of toluene diisocyanate, soak the aramid chopped fiber 1313 in the aqueous solution for 24 hours, then wash it repeatedly with distilled water, dry it for later use, and obtain the modified aramid chopped fiber 1313;

[0059] (2) Take 400g of MHR070 epoxy resin and 150g of ERL4221D epoxy resin, mix and preheat to 65°C, use a disintegrator to disperse 80g of modified aramid chopped fiber 1313 into the epoxy resin solution, and add 6g of wetting and dispersing agent in turn 2070, 2.5g defoamer BYK052, 2.5g coupling agent KH792, after the dispersion is completed, cool down to 20°C to obtain aramid fiber epoxy slurry A;

[0060] (3) Get 40g ethoxylated and propoxylated glycerol triglycidyl ether, 40g dicyclopentadiene dicarboxylic acid diglycidyl ester, 80g isophorone diamine curing agent, 30g terephthalic acid di Hydrazide, 60g triethyl phosphate, and 5g KH792 were evenly dispersed in the active diluent to obtain component B;

[0061] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com