A kind of ultra-low ash polypropylene and polypropylene lithium battery diaphragm material

A lithium battery separator and polypropylene technology, which is used in lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc. Mechanical properties, low dielectric loss, moisture resistance and no water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 prepares ultra-low ash polypropylene

[0062] In the Ziegler-Natta catalyst used in the present embodiment, the Ti content is 2.5wt%, the Mg content is 18.5wt%, the diisobutyl phthalate (DIBP) content is 8.3wt%, and the volatile matter is 2.9wt%. ;

[0063] Add propylene to the reactor, and add Ziegler-Natta catalyst, cocatalyst (triethylaluminum), electron donor Donor (CMMS), catalyst is added according to the output of 40kg polypropylene / g catalyst, triethylaluminum / Ti (Ti element in the catalyst) = 64

[0064] Ti element in the catalyst / propylene monomer=2.45, triethylaluminum / DONOR=3.18, stir evenly, control the reactor temperature at 72±1°C, the reaction pressure at 3.0-3.2MPa, and the hydrogen concentration at 800ppm. Thus, ultra-low ash polypropylene resin is obtained.

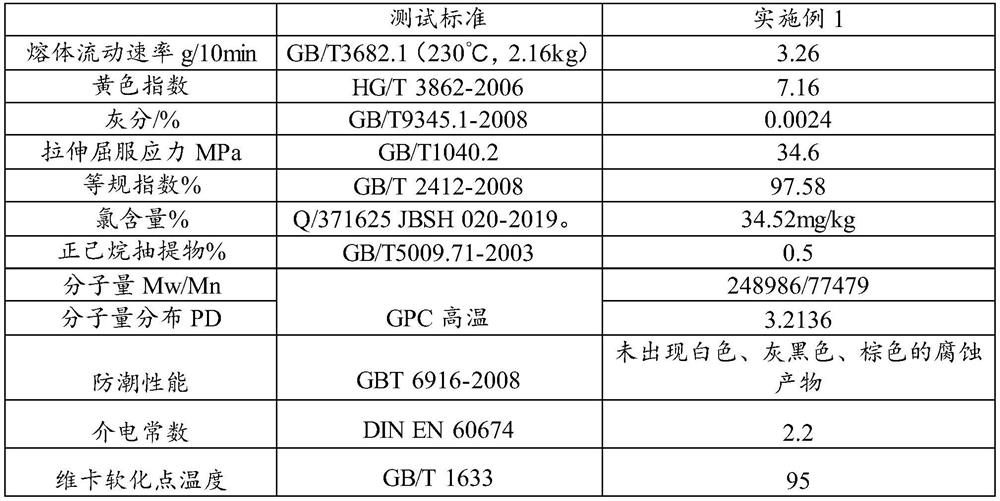

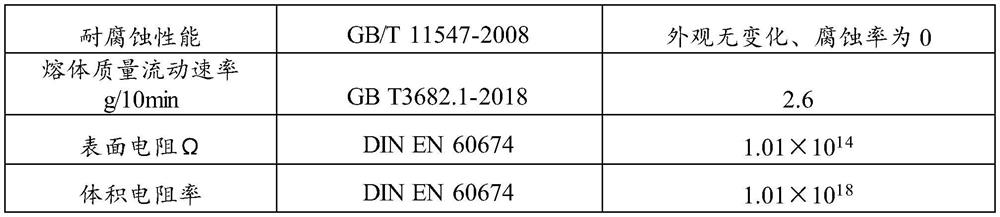

[0065] The obtained polypropylene resin properties are shown in Table 1,

[0066] Table 1 The performance of ultra-low ash polypropylene resin in Example 1 of the present applica...

Embodiment 2~8

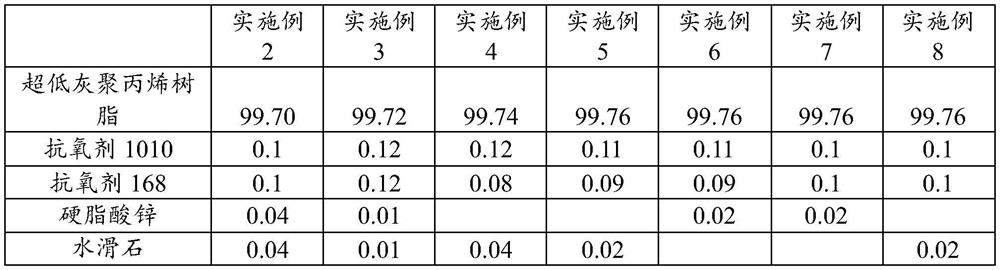

[0070] According to the ratio in Table 3, add ultra-low ash polypropylene resin, antioxidant, and halogen absorbent into a 10L high-speed mixing mixer, mix for 30 minutes at normal temperature and pressure, and then extrude with a Coperion extrusion granulator. After granulation, the temperature of each section was controlled between 165-240° C., and the temperature of each section was shown in Table 2 to obtain a polypropylene resin material for a lithium battery separator.

[0071] Table 2 The temperature of each section of extrusion granulation in Examples 2 to 8 of the present application

[0072] zone 1 Zone 2 District 3 District 4 District 5 District 6 District 7 District 8 nose temperature / ℃ 175 180 175 180 180 175 180 185 190

[0073] Each group distribution ratio in the embodiment 2~8 of the present application of table 3

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com