A kind of carbon opposite electrode perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems affecting long-term stability, mechanical damage to porous membranes, photoelectric conversion efficiency attenuation, etc., to reduce adverse effects and reduce filling The effect of reducing the amount of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

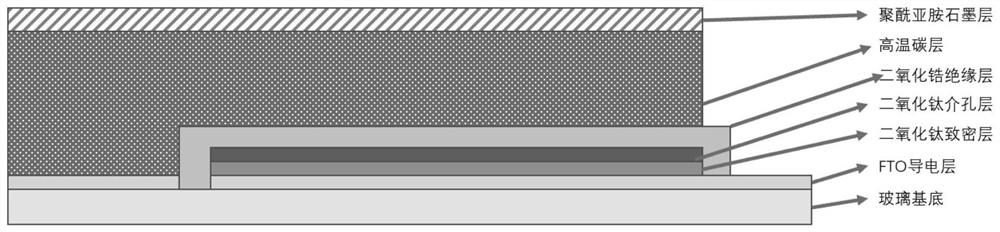

[0042] The invention provides a method for preparing a carbon counter electrode perovskite solar cell, comprising the steps of:

[0043] (1) sequentially prepare a dense layer, a photoanode mesoporous layer and an insulating layer on a transparent conductive substrate;

[0044] (2) preparing a first carbon layer on the insulating layer described in step (1);

[0045] (3) transferring the perovskite precursor solution to the surface of the first carbon layer described in step (2); the first carbon layer is a porous carbon layer;

[0046] (4) preparing a second carbon layer on the surface of the first carbon layer, the second carbon layer is a patterned graphite sheet to obtain a carbon counter electrode perovskite solar cell.

[0047] In some embodiments, the step (2) specifically includes: printing the carbon paste on the insulating layer by a screen printing machine, and then sintering at 380-450° C. to obtain the first carbon layer; here the carbon paste is also It is call...

Embodiment 1

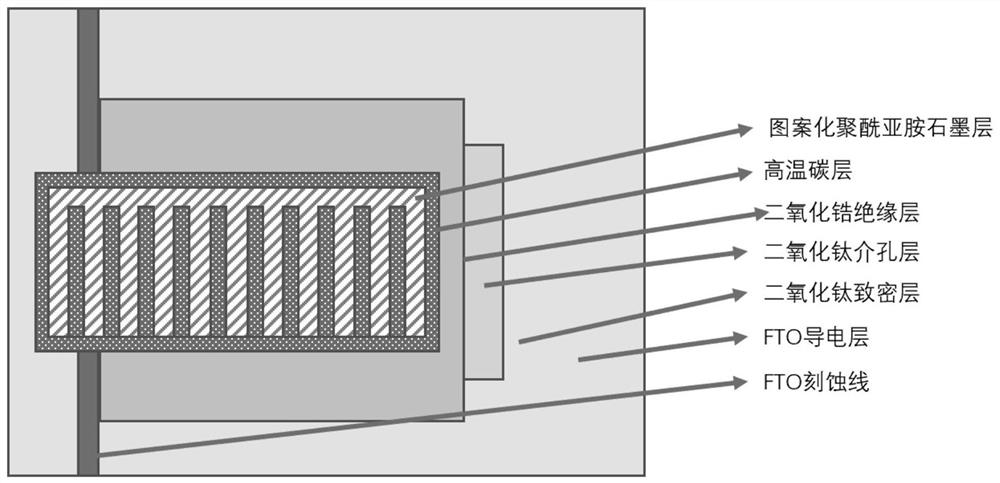

[0079] (1) Use a cutting machine to cut the conductive glass into glass sheets of a certain size. For example, the preferred size in this embodiment is 100mm × 100mm, but it can also be other sizes. Use a laser to place a certain distance from one edge of the conductive layer of the glass sheet Etch an insulating strip parallel to the edge (preferably in this embodiment, for example, 5 mm from the edge), and etch a plurality of parallel insulating strips in the remaining area to divide the glass sheet into multiple regions, such as this embodiment It is preferred to etch 4 parallel insulating strips to divide the glass sheet into five positive and negative electrode regions, so that the conductive layer cannot be completely conducted, and the etched glass sheet is ultrasonically cleaned with detergent, distilled water, and absolute ethanol cleaning. For the size of the positive electrode region or the negative electrode region, especially its width, it can be specifically sele...

Embodiment 2

[0088] In this embodiment, steps (1), (2), (3), (4), (5) and (6) are the same as in embodiment 1.

[0089] (7) Cut the shape of the 25 μm thick thermally conductive graphite sheet film to the same size as the first carbon layer, and use laser technology to pattern the graphite sheet into a comb shape, such as figure 2 As shown in , after the perovskite precursor solution on the surface of the first carbon layer diffuses to a uniform distribution, the heat-conducting graphite sheet is placed on the surface solution of the first carbon layer, and then it is left standing still to make it fill to each layer through the infiltration process. In the porous thin film layer, each porous thin film layer includes the first carbon layer, the ZrO 2 insulating layer, the TiO 2 The mesoporous layer and the dense layer; after the perovskite is fully infiltrated, the solar cell is annealed at 50 degrees Celsius to complete the preparation.

[0090] The present invention combines the advan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com