Resource utilization method of stainless steel pickling waste water crystallized salt sludge

A technology of pickling wastewater and crystallized salt, applied in the field of comprehensive utilization of resources, to achieve the effects of low production cost, environmental friendliness, high-efficiency enrichment and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

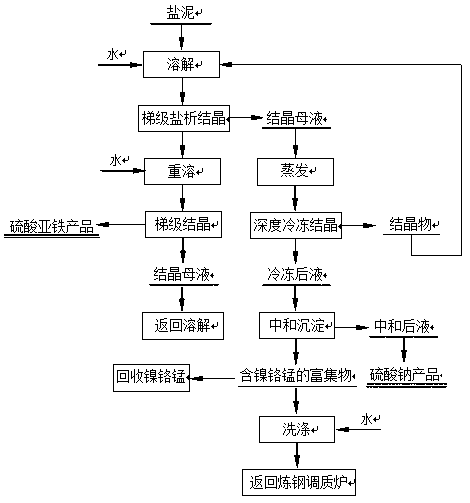

Image

Examples

Embodiment 1

[0026] Embodiment 1: In this embodiment, the salt mud contains Fe 25.12%, Ni 0.50%, Cr 0.40%, Mn 2.31%, and free acid 8.65%;

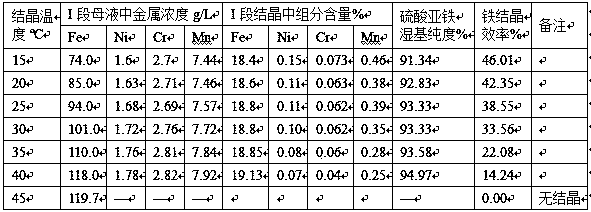

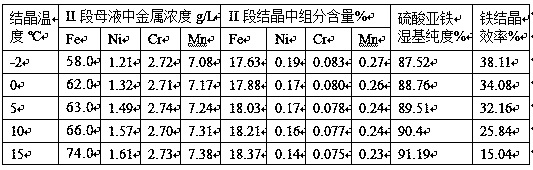

[0027] The temperature selection of stage I cooling crystallization and stage II cooling crystallization in the method of cascade crystallization:

[0028] Add stainless steel pickling wastewater crystalline salt mud into water and heat to a temperature of 65°C to dissolve to obtain a ferrous sulfate crude solution, wherein the total iron ion concentration of the ferrous sulfate crude solution is 120g / L, and at a stirring speed of 50r / min, the The crude ferrous sulfate solution is subjected to stage I cooling crystallization to obtain the crude salt of ferrous sulfate crystallization stage I and the crystallization mother liquor of stage I, wherein the stage I cooling crystallization is to rapidly cool the crude ferrous sulfate solution from 65°C to 20~40°C and crystallize 10min,

[0029] After testing, the metal concentration in the stage I crystalli...

Embodiment 2

[0039] Embodiment 2: In this embodiment, the salt mud contains Fe 25.12%, Ni 0.11%, Cr 0.12%, Mn 0.51%, and free acid 5.24%;

[0040] A resource utilization method of crystalline salt mud from stainless steel pickling wastewater (see figure 1 ),Specific steps are as follows:

[0041] (1) Separation of impurity element iron and valuable metal nickel, chromium and manganese: add stainless steel pickling wastewater crystalline salt mud into water and heat to a temperature of 70°C to dissolve to obtain a crude solution of ferrous sulfate, with a stirring rate of 50r / min , the crude ferrous sulfate solution is subjected to I stage cooling crystallization to obtain the I stage ferrous sulfate crystalline coarse salt and the I stage crystallization mother liquor, and the I stage crystallization mother liquor is carried out II stage cooling crystallization to obtain the II stage ferrous sulfate crystal coarse salt and the II stage crystallization Mother liquor; wherein the concentrat...

Embodiment 3

[0045] Embodiment 3: In this embodiment, the salt mud contains Fe 12.24%, Ni 0.68%, Cr 0.59%, Mn 2.87%, and free acid 14.88%;

[0046] A resource utilization method of crystalline salt mud from stainless steel pickling wastewater (see figure 1 ),Specific steps are as follows:

[0047] (1) Separation of impurity element iron and valuable metal nickel, chromium and manganese: add stainless steel pickling wastewater crystalline salt mud into water and heat to a temperature of 55°C to dissolve to obtain a crude solution of ferrous sulfate, with a stirring rate of 100r / min , the crude ferrous sulfate solution is subjected to I stage cooling crystallization to obtain the I stage ferrous sulfate crystalline coarse salt and the I stage crystallization mother liquor, and the I stage crystallization mother liquor is carried out II stage cooling crystallization to obtain the II stage ferrous sulfate crystal coarse salt and the II stage crystallization Mother liquor; wherein the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com