Polymerizable photoinitiator based on benzanthrone and preparation method of polymerizable photoinitiator

A technology for polymerizing a photoinitiator and benzranthrone, which is applied in the field of a polymerizable photoinitiator based on benzranthrone and its preparation, can solve the problems of yellowing, easy sublimation and migration, and bad odor of cured products, and reduces the Volatility and mobility, improved compatibility, reduced mobility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

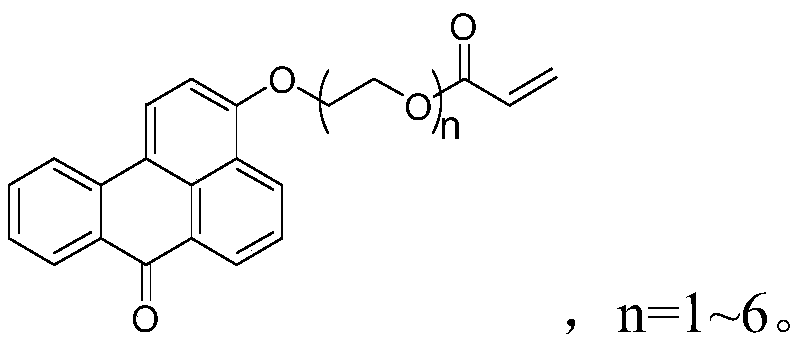

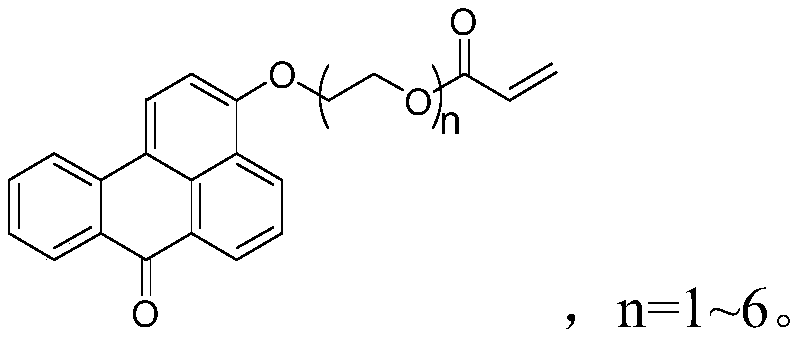

[0032] The synthetic equation of the polymerizable photoinitiator based on benzothrone:

[0033] Wherein n=1~6.

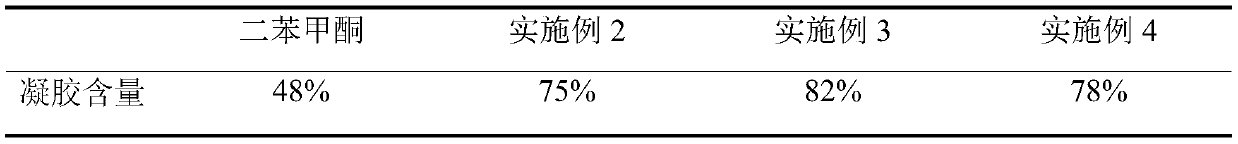

Embodiment 2

[0035] The preparation method of the polymerizable photoinitiator based on benzoanthrone comprises the following steps:

[0036] (1) Add 200g of polyethylene glycol (PEG100), 50g of 3-bromobenzoxanthrone and 100g of potassium carbonate successively in a three-necked flask, heat up to 120°C after stirring, and monitor the reaction process with TLC (polyethylene:polypropyleneethylene glycol) ester=1:1), after reacting for 8 hours, cool to room temperature, add 250mL dichloromethane and 250mL water successively, stir for 30min and then stand for stratification to obtain aqueous phase and organic phase, add 250mL dichloromethane to the obtained aqueous phase Extract again, combine the extracted product with the organic phase, add anhydrous sodium sulfate to dry, distill methylene chloride under reduced pressure at 40°C in a water bath, and obtain an intermediate product, which is a yellow liquid (50g), which is directly used for Step (2); Wherein vacuum distillation is prior art; ...

Embodiment 3

[0039] The preparation method of the polymerizable photoinitiator based on benzoanthrone comprises the following steps:

[0040] (1) Add 200g of polyethylene glycol (PEG200), 50g of 3-bromobenzoxanthrone and 100g of potassium carbonate successively in a three-necked flask, stir and then heat up to 125°C. The reaction process is monitored by TLC (polyethylene:polypropyleneethylene glycol) ester=1:1), after reacting for 8 hours, cool to room temperature, add 250mL dichloromethane and 250mL water successively, stir for 30min and then stand for stratification to obtain aqueous phase and organic phase, add 250mL dichloromethane to the obtained aqueous phase Extract again, combine the extracted product with the organic phase, add anhydrous sodium sulfate to dry, and distill off methylene chloride under reduced pressure at 30°C in a water bath to obtain an intermediate product. The intermediate product is a yellow liquid (50 g), which is directly used for Step (2); Wherein vacuum dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com