Limestone powder calcining furnace

A technology of limestone powder and calciner, applied in the field of limestone powder calciner, can solve the problems of low discharge efficiency, large floor space, waste of resources, etc., and achieves the advantages of slowing down the unloading speed, effectively utilizing waste heat, and high discharging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

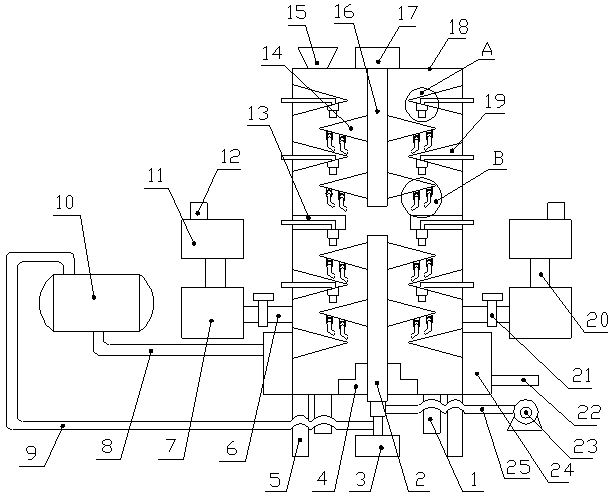

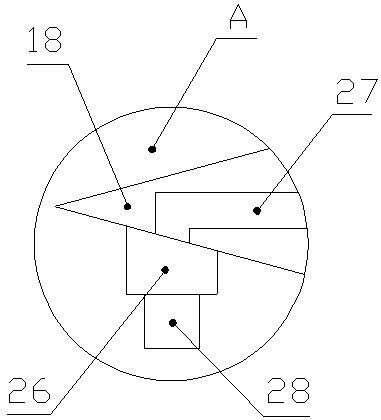

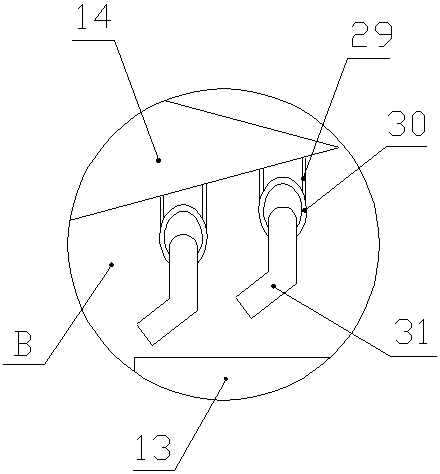

[0026] like Figure 1-4As shown, a limestone powder calciner includes a furnace body 18, the lower surface of the furnace body 18 is fixedly connected with a support leg 5, and the left side of the upper surface of the described furnace body 18 is fixedly connected with a feed hopper 15, so The middle part of the upper surface of the furnace body 18 is fixed with a motor B17, the output shaft of the motor B17 is connected to the stirring shaft B16, and the lower end of the stirring shaft B16 penetrates the upper side wall of the furnace body 18 and extends into the furnace body 18. In the upper part, a motor A3 is arranged below the furnace body 18, the output shaft of the motor A3 is connected to a stirring shaft A2, and the upper end of the stirring shaft A2 penetrates the lower side wall of the furnace body 18 and extends into the furnace body 18 The lower part, the stirring shaft A2 and the stirring shaft B16 are fixedly connected with stirring blades 14, the middle part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com