A carbonization process based on constant temperature carbonization

A carbonization and process technology, which is applied in the carbonization process field of constant temperature carbonization method, can solve the problems of environmental pollution, high labor intensity, air pollution, etc., and achieve the effects of improving production efficiency, simple synthesis process and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] see figure 1 , a carbonization process based on constant temperature carbonization, the carbonization process comprises the following steps:

[0067] S1. Powder: the wood is crushed into sawdust by the crushing device;

[0068] S2. Feeding: the sawdust is transported to the drying device by the conveying device for drying;

[0069] S3. Drying: the sawdust is heated and dried in a drying device, the heating temperature of the wood is 200-250 degrees Celsius, and the drying duration is about 16-25 minutes;

[0070] S4. Intermediate feed: the dried sawdust is conveyed into the carbonization device by the intermediate feed screw;

[0071] S5. Carbonization: the temperature in the carbonization device is W1, the temperature W1 is a fixed constant temperature value, and the carbonization duration is T1;

[0072] S6. Charcoal production: after the wood chips are charcoalized, enter the water-cooling structure for cooling to obtain the produced charcoal.

[0073] In the ste...

Embodiment 2

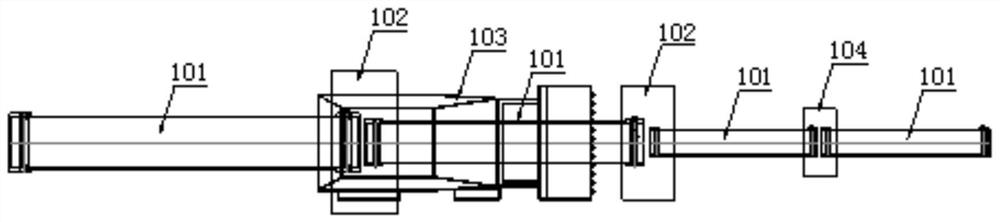

[0082] Such as Figure 2-8 As mentioned above, the present invention also discloses a charcoal production equipment based on constant temperature carbonization, including a pulverizer, a conveyor belt, a drying furnace, a carbonization device, a combustion device and a physical activation device. The pulverizer, conveyor belt, drying The furnace, the carbonization device and the physical activation device are connected in sequence, and the combustion device is connected with the drying furnace, the carbonization device and the physical activation device. The outlet end of the steam furnace of the combustion device is connected to the cavity and the activation drum, one outlet end of the carbonization furnace is connected to the inlet end of the combustion furnace, and the other outlet end of the carbonization furnace is connected to the feeding screw. The outlet end of the combustion furnace is connected with a drying furnace.

[0083] The carbon making device includes a tran...

Embodiment 3

[0103] The difference between this embodiment and the above embodiment is that the constant temperature carbonization device includes a heater, a controller, a detector, and a power supply; the heater and the detector are all connected to the controller; the power supply can provide multiple A current / voltage to power heaters, controllers, detectors. The heater is an electric heater, and the detector is a temperature sensor, especially a thermocouple temperature sensor. The electric heater is heated, and the thermocouple temperature sensor detects the real-time temperature of the carbonization device. When the real-time temperature does not reach the preset threshold value of the controller, the controller controls the electric heater to keep heating, and the temperature continues to rise; When the thermocouple temperature sensor detects that the real-time temperature of the carbonization device reaches the preset threshold value of the controller, the heater reduces the heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com