Iron-doped cobalt phosphide microsphere electrode material with flower-like structure, preparation method and application thereof

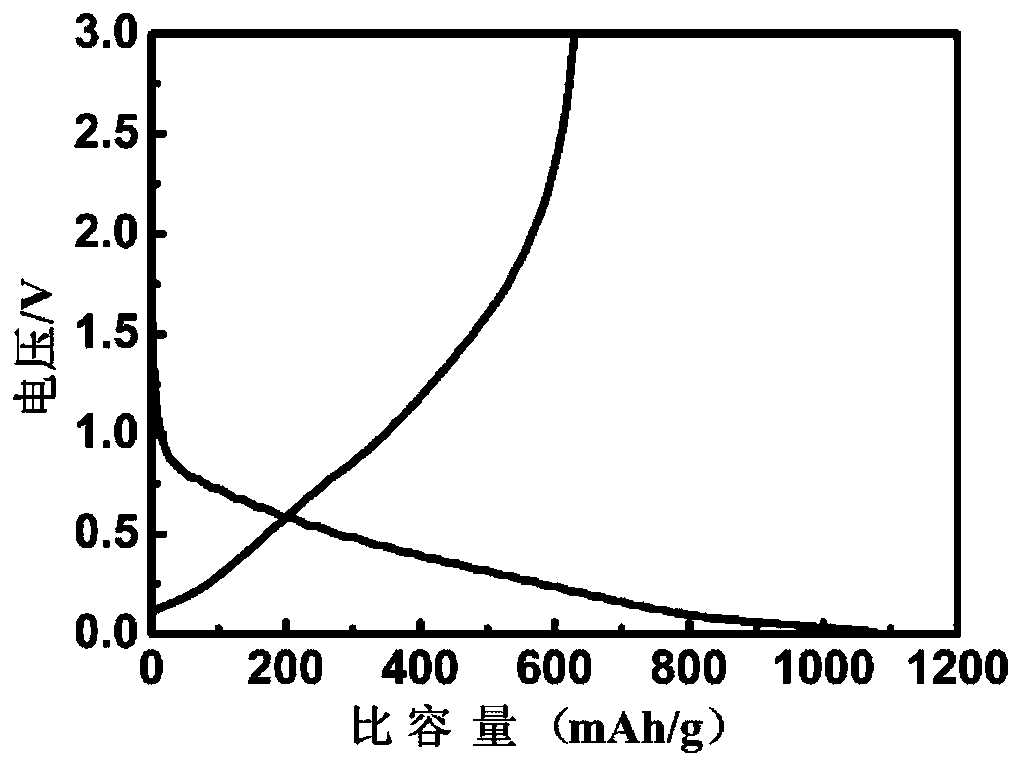

A flower-like structure, iron-doped technology, applied to chemical instruments and methods, phosphides, phosphorus compounds, etc., can solve the problems of poor specific capacity and cycle stability, achieve electrochemical stability improvement, suppress crushing, and ease volume The effect of swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

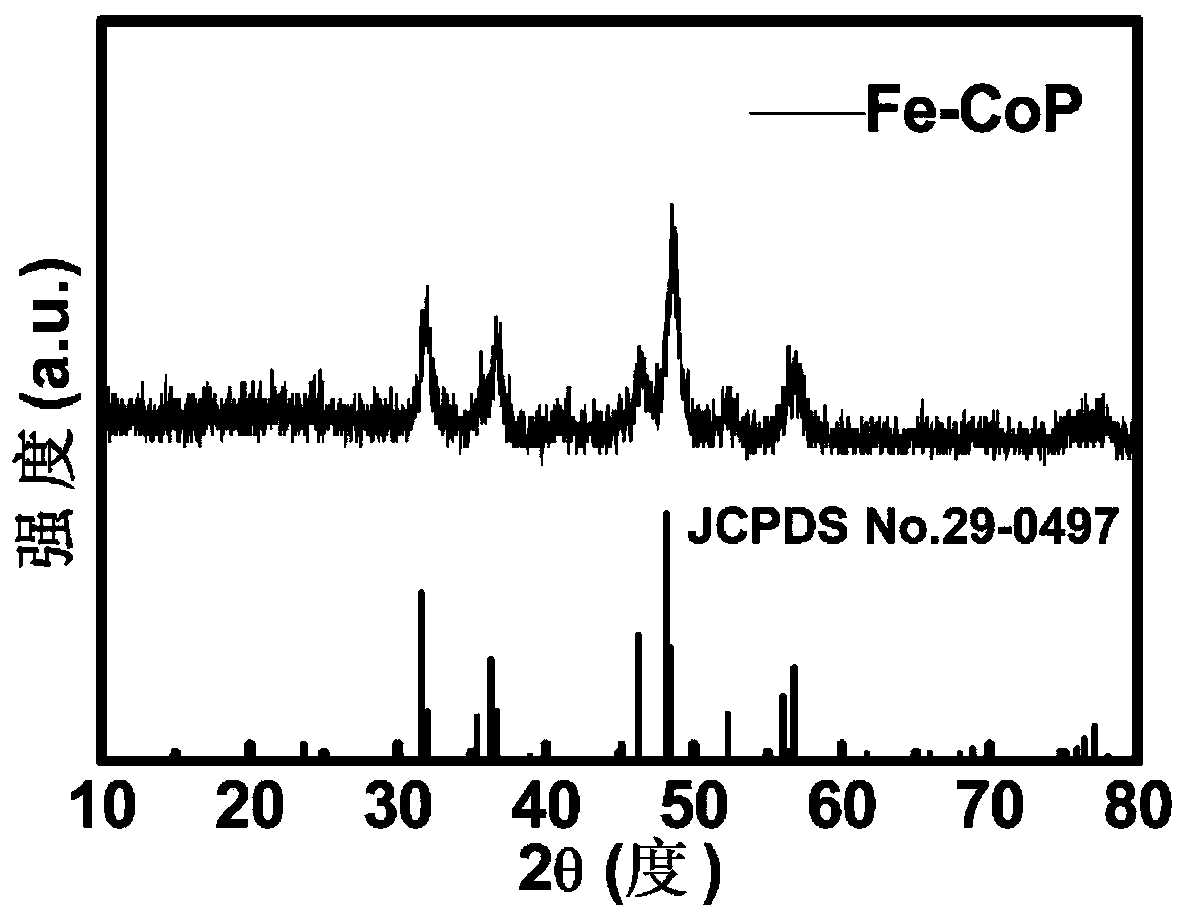

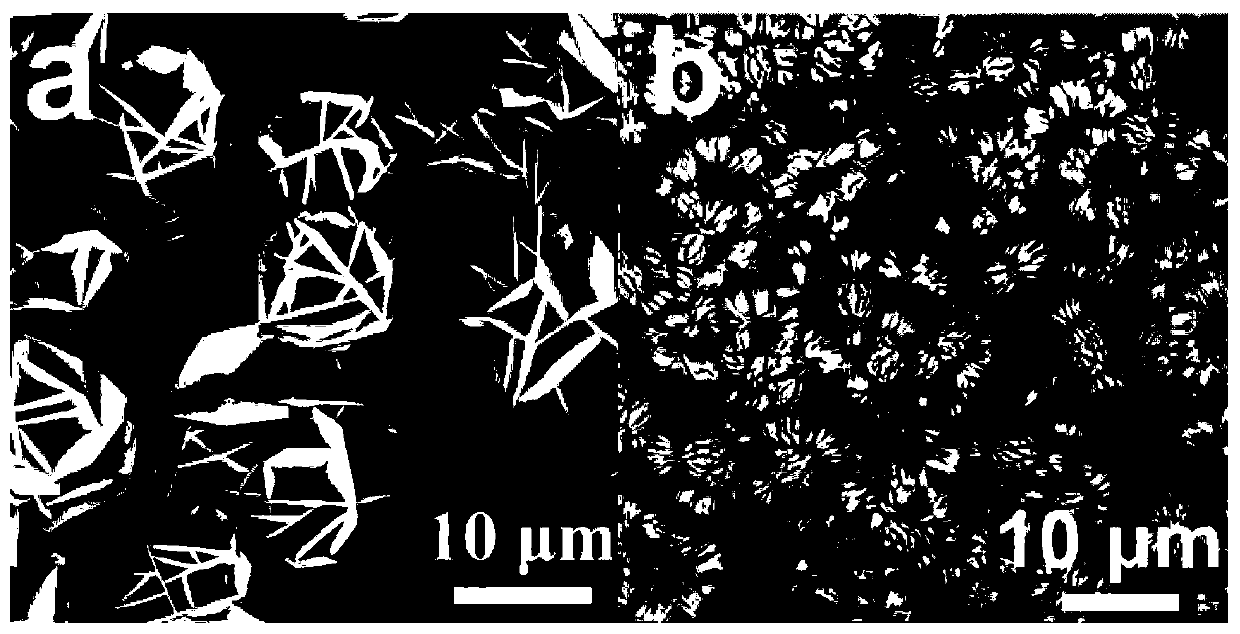

[0028] The osmanthus leaves (fresh osmanthus leaves picked from the campus of Jiangsu University of Science and Technology) that had been carbonized (calcined at 800°C for 2 hours under the protection of nitrogen) and then treated in 2mol / L nitric acid solution at 60°C for 6 hours were used as the base carbon film and immersed in 0.08mol / LCo(NO 3 ) 2 , 0.02mol / L Fe(NO 3 ) 3 , 0.5mol / L CO(NH 2 ) 2 , 0.3mol / L NH 4 The hydrothermal reaction of the F mixed solution was carried out at 100°C for 4 hours, and the precursor product was obtained by cooling; the obtained precursor product was washed and dried at 60°C, and then added sodium hypophosphite at 350°C under a nitrogen atmosphere for phosphating treatment 2 hours, NaH 2 PO 2 The mass ratio to the precursor product is 30:1, and after cooling, iron-doped cobalt phosphide microspheres with a flower-like structure are obtained.

Embodiment 2

[0032] After carbonization (calcined at 800°C for 2 hours under the protection of nitrogen) and then treated in 2mol / L nitric acid solution at 60°C for 6 hours, as the base carbon film, immerse the leaves containing 0.08mol / L Co(NO 3 ) 2 , 0.02mol / L Fe(NO 3 ) 3 , 0.5mol / LCO(NH 2 ) 2 , 0.3mol / LNH 4The hydrothermal reaction of the F mixed solution was carried out at 100°C for 8 hours, and cooled; the obtained precursor product was washed and dried at 60°C, and then phosphating was carried out at 350°C under a nitrogen atmosphere for 2 hours, NaH 2 PO 2 The mass ratio to the precursor product is 30:1, and after cooling, iron-doped cobalt phosphide microspheres with a flower-like structure are obtained.

Embodiment 3

[0034] After carbonization (calcined at 800°C for 2 hours under the protection of nitrogen) and then treated in 4mol / L nitric acid solution at 60°C for 10 hours, the osmanthus leaves were used as the base carbon film and immersed in the carbon film containing 0.08mol / L Co(NO 3 ) 2 , 0.02mol / L Fe(NO 3 ) 3 , 0.5mol / L CO(NH 2 ) 2 , 0.3mol / LNH 4 The hydrothermal reaction of the F mixed solution was carried out at 100°C for 4 hours, and then cooled; the obtained precursor product was washed and dried at 60°C, and then phosphating was carried out at 350°C under a nitrogen atmosphere for 2 hours, NaH 2 PO 2 The mass ratio to the precursor product is 30:1, and after cooling, iron-doped cobalt phosphide microspheres with a flower-like structure are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com