Preparation method of ion exchange membrane and application thereof

A technology of ion-exchange membrane and ion-exchange capacity, which is applied in energy storage, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as poor mechanical stability and low ion conductivity, and achieve improved energy conversion efficiency and high Effect of ion selectivity, high mechanical and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Dissolve perfluorosulfonic acid resins with ion exchange capacities of 0.9mmol / g, 1.0mmol / g, 1.1mmol / g, and 1.2mmol / g in dimethyl sulfoxide to obtain the concentration of perfluorosulfonic acid resin Be 12wt% perfluorosulfonic acid resin solution;

[0022] 2) Immerse the prepared perfluorosulfonic acid resin solution on a clean polytetrafluoroethylene porous mesh cloth for 1 hour, then hang it in a blast drying oven at 125°C and dry it for 10 minutes, then repeat the above dipping-drying process The procedure is more than 3 times, and the perfluorosulfonic acid membrane supported by mesh cloth is prepared;

[0023] 3) Soak the mesh-supported perfluorosulfonic acid membrane prepared in step 2) in deionized water at 80°C under normal pressure, boil it for 1 hour, rinse it several times and dry it to obtain the ion exchange membrane J1, J2, J3, J4.

Embodiment 2

[0025] 1) Dissolve perfluorosulfonic acid resins with ion exchange capacities of 0.9mmol / g, 1.0mmol / g, 1.1mmol / g, and 1.2mmol / g in dimethyl sulfoxide to obtain the concentration of perfluorosulfonic acid resin Be 15wt% perfluorosulfonic acid resin solution;

[0026] 2) Coat the prepared perfluorosulfonic acid resin solution on a clean polytetrafluoroethylene porous mesh cloth with a scraper, then place it in a blast drying oven at 125°C and dry it for 3 hours, then repeat the above dipping-drying The drying procedure is more than 3 times, and the perfluorosulfonic acid membrane supported by mesh cloth is prepared;

[0027] 3) Soak the mesh-supported perfluorosulfonic acid membrane prepared in step 2) in deionized water at 80°C under normal pressure, boil for 1 hour, rinse and dry it several times, and then the ion-exchange membrane G1, G2, G3, G4.

Embodiment 3

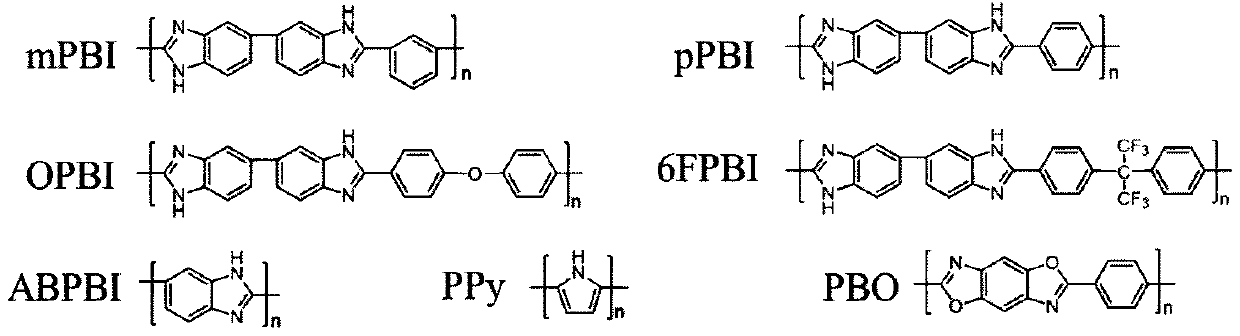

[0029] mPBI was stirred and dissolved in N-methylpyrrolidone (NMP) at 100-180°C to form a clear and transparent solution with a concentration of 0.001-1wt%, and the undissolved mPBI particles were removed by filtration, and then the ion exchange membrane J1, J2, J3, J4 and ion exchange membranes G1, G2, G3, G4 were soaked flatly in the PBI solution for 5s-24h respectively, after soaking, the membranes were taken out and hung in a blast drying oven at 100-200°C After drying for 4 hours and lowering to room temperature, seal the film and store it in a plastic bag for later use.

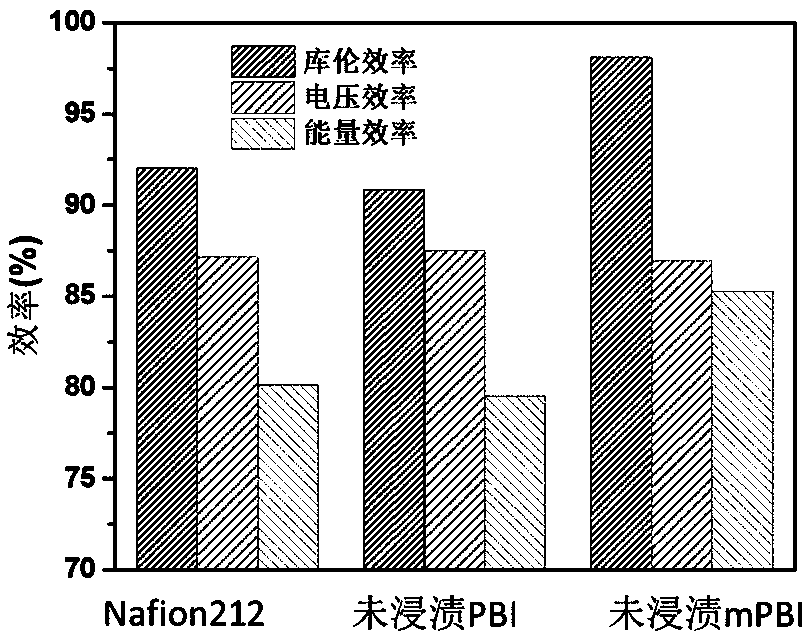

[0030] Test the water absorption rate, swelling rate and vanadium ion permeability of different impregnated membranes. The test methods and results are as follows:

[0031] 1) Water absorption and swelling rate:

[0032] Cut the obtained membrane into a size of 1cm×4cm, soak it in deionized water for 24 hours at room temperature, take it out, blot the water on the surface of the membrane with filter pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| voltage efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com