A kind of stock solution of plant wall breaking agent and its preparation method and application

A plant-based raw material and plant technology, applied in the field of plant wall breaking, can solve the problems of difficult operation, low wall breaking rate, and high risk of breaking the wall technology, so as to facilitate digestion and absorption of animals, high breaking efficiency, and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

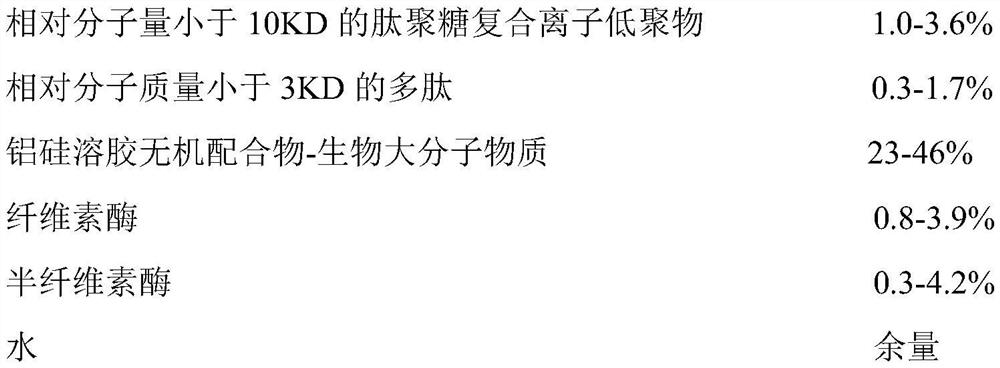

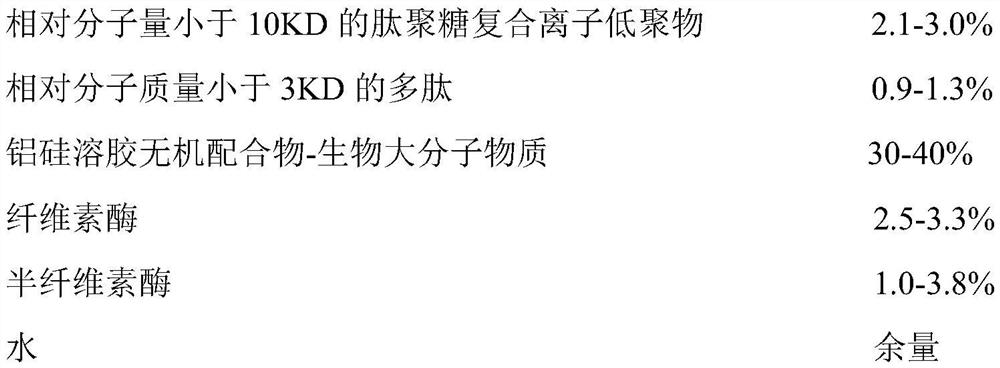

Examples

Embodiment 1

[0061] (1) Cultivate seed liquid: with 30g soybean peptone, 30g casein peptone, 450g glucose, 100g fructooligosaccharide, 150g isomaltooligosaccharide, 50g xylooligosaccharide, 5g sodium carbonate, 5g sodium chloride, 2g potassium chloride as The main components of the culture medium were dissolved by adding 1000ml of deionized water, then dissolving the auxiliary materials 6g of sodium aluminosilicate, 2g of zinc oxide, 0.01g of silver carbonate, and 20g of chitosan in 500ml of deionized water to make a culture medium. ℃, autoclave for 50 minutes, cool to 37 ℃, inoculate Lactobacillus delbrueckii and Bacillus subtilis strains on the medium for fermentation, and the product is a peptidoglycan complex ion oligomer with a relative molecular weight less than 10KD. Enter sterile compressed air for aerobic fermentation;

[0062] (2) Prepare a fermentation liquid: when the seed liquid OD 450nm = 1.0-2.0, inoculate in the initial fermenter; stop the fermentation when the bacterium g...

Embodiment 2

[0068] (1) Cultivate seed liquid: with 80g soybean peptone, 50g casein peptone, 800g glucose, 400g fructooligosaccharide, 350g isomaltooligosaccharide, 100g xylooligosaccharide, 10g sodium carbonate, 10g sodium chloride, 5g potassium chloride as Add 1000ml of deionized water and stir to dissolve the main components of the culture medium, then dissolve the auxiliary materials 18g of sodium aluminosilicate, 5g of zinc oxide, 0.05g of silver carbonate, and 45g of chitosan in 500ml of deionized water to make a culture medium. ℃, 50 minutes of autoclaving, cooling to 37 ℃, inoculating caseibacterium and bacillus licheniformis in the culture medium for fermentation, the product is peptidoglycan complex ionic oligomer with a relative molecular weight less than 10KD, intermittently fed without Bacteria compressed air for aerobic fermentation;

[0069] (2) Prepare a fermentation liquid: when the seed liquid OD 450nm When = 1.0-2.0, inoculate in the initial fermenter; stop the fermenta...

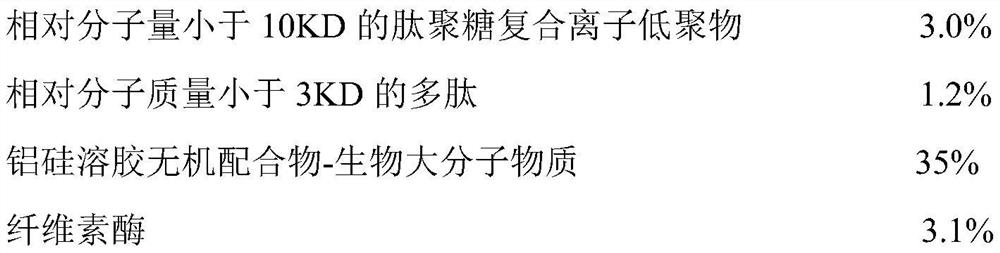

Embodiment 3

[0075](1) Cultivate seed liquid: with 101g soybean peptone, 90g casein peptone, 1100g glucose, 700g fructooligosaccharide, 850g isomaltooligosaccharide, 200g xylooligosaccharide, 20g sodium carbonate, 20g sodium chloride, 10g potassium chloride as The main components of the culture medium were dissolved by adding 1000ml of deionized water, and then 25g of sodium aluminosilicate, 10g of zinc oxide, 0.5g of silver carbonate, and 99g of chitosan were dissolved in 500ml of deionized water to make a culture medium. ℃, 50 minutes of autoclaving, cooling to 37 ℃, inoculating Lactobacillus plantarum and Bacillus amyloliquefaciens on the culture medium for fermentation, the product is a peptidoglycan complex ion oligomer with a relative molecular weight less than 10KD, intermittently passed Enter sterile compressed air for aerobic fermentation;

[0076] (2) Prepare a fermentation liquid: when the seed liquid OD 450nm When = 1.0-2.0, inoculate in the initial fermenter; stop the ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com