Composite filtering equipment for biomass gas

A biomass gas and composite filtration technology, which is applied in the fields of combining devices, manufacturing combustible gas, condensing non-gaseous materials and gas purification, etc., can solve the problems of complex structure of gas filtration devices, large installation and maintenance workload, and unsatisfactory gasification effect. , to achieve the effect of compact structure, convenient installation and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

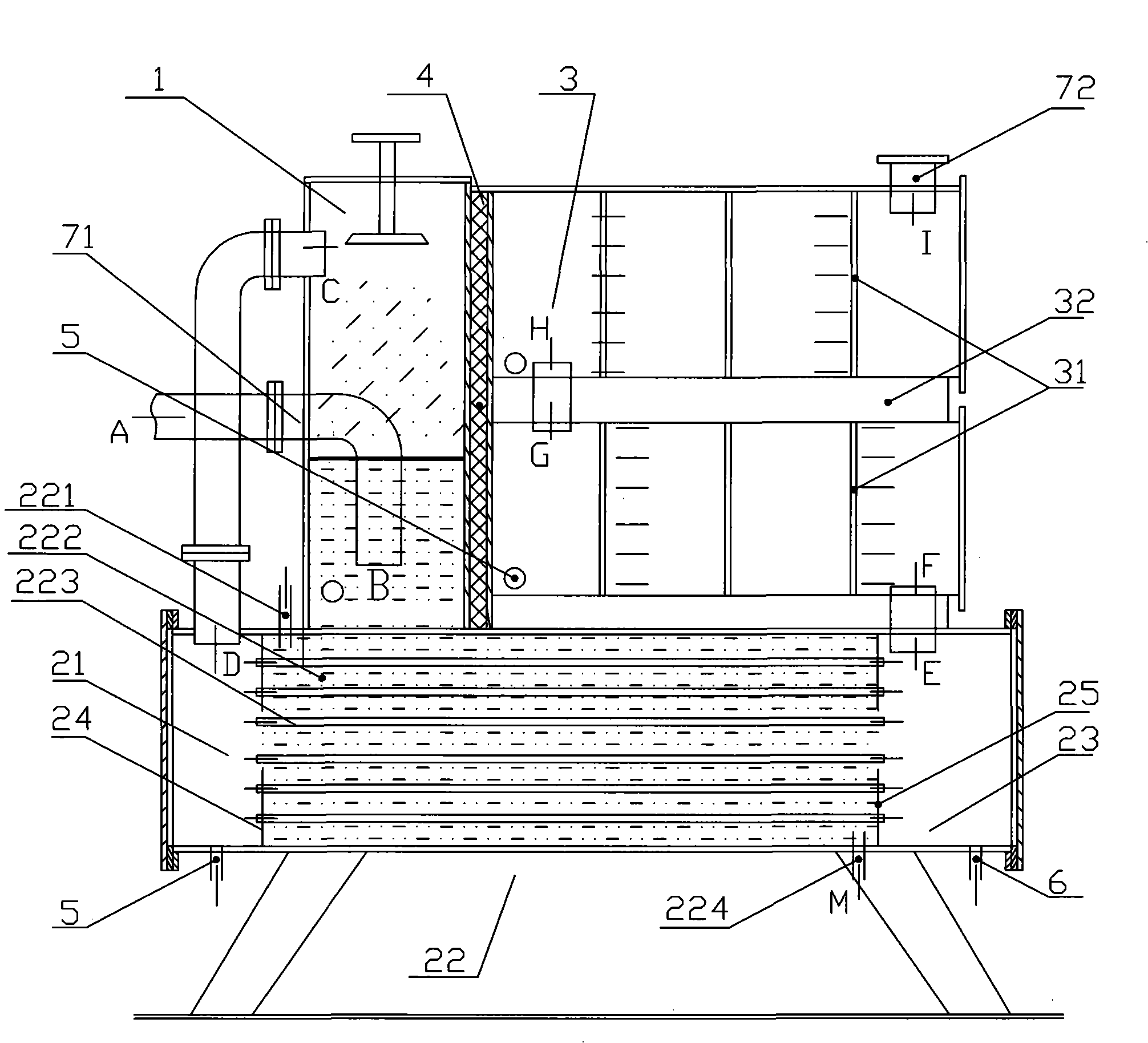

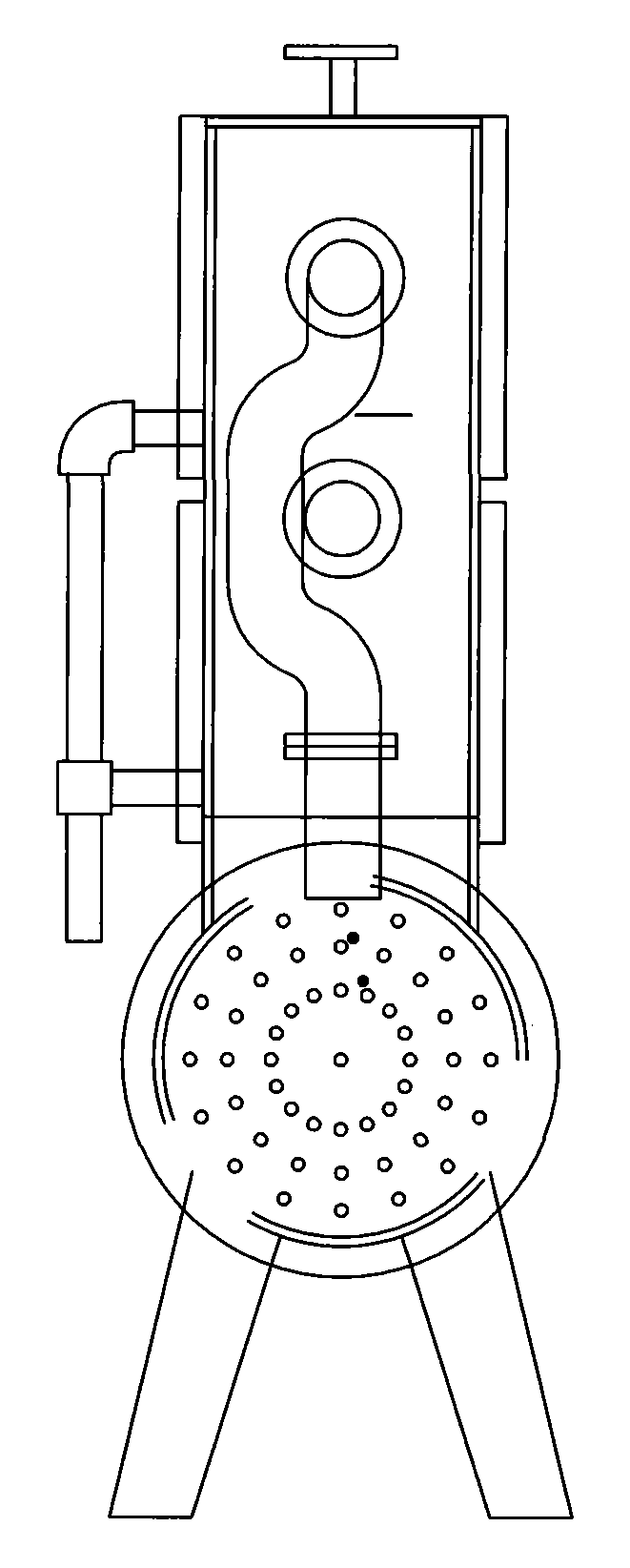

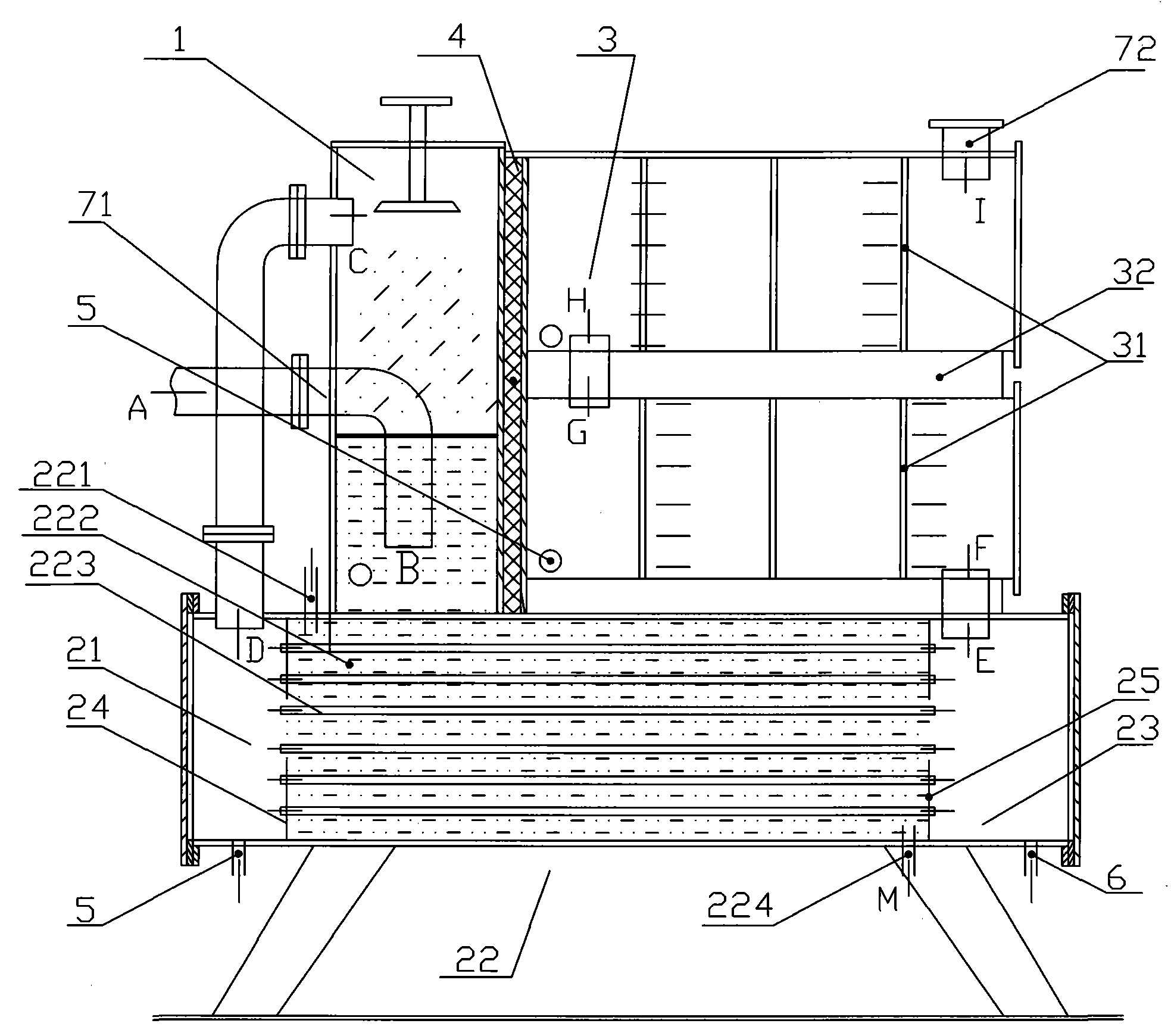

[0041] Biomass gas composite filter device, such as figure 1 and figure 2 As shown, it includes an integrated composite structure of a water bath shower 1, a heat exchanger 2 and a dry filter 3; its interior is sequentially connected from the upper part of the water bath shower 1 to the inlet of the heat exchanger through a gas pipeline. The air chamber 21 is connected to the bottom of the dry filter 3 from the air outlet chamber 23 of the heat exchanger; the composite filter device is provided with blowdown valves 5, 6 at the bottom of the heat exchanger 2;

[0042] The water-bath shower 1 is a container with a shower, including inlet and outlet pipes and gas pipelines, and water of a certain height is stored in the water-bath shower 1; the air inlet of the composite filter device 71 is located in the middle of the water bath shower 1 and above the highest water level of the water bath, and the gas transmission pipeline for air intake is inserted into the water stored in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com