Device for producing hydroxypropyl methyl cellulose in dustless manner

A technology of hydroxypropyl methylcellulose and a production device, which is applied in the field of dust-free hydroxypropyl methylcellulose production devices, can solve the problem that the dust removal effect of the dust collector is not ideal, the rigid operator is healthy, and the dust cannot be effectively Recycling and other issues to achieve the effect of improving product quality, extending drying time, and good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

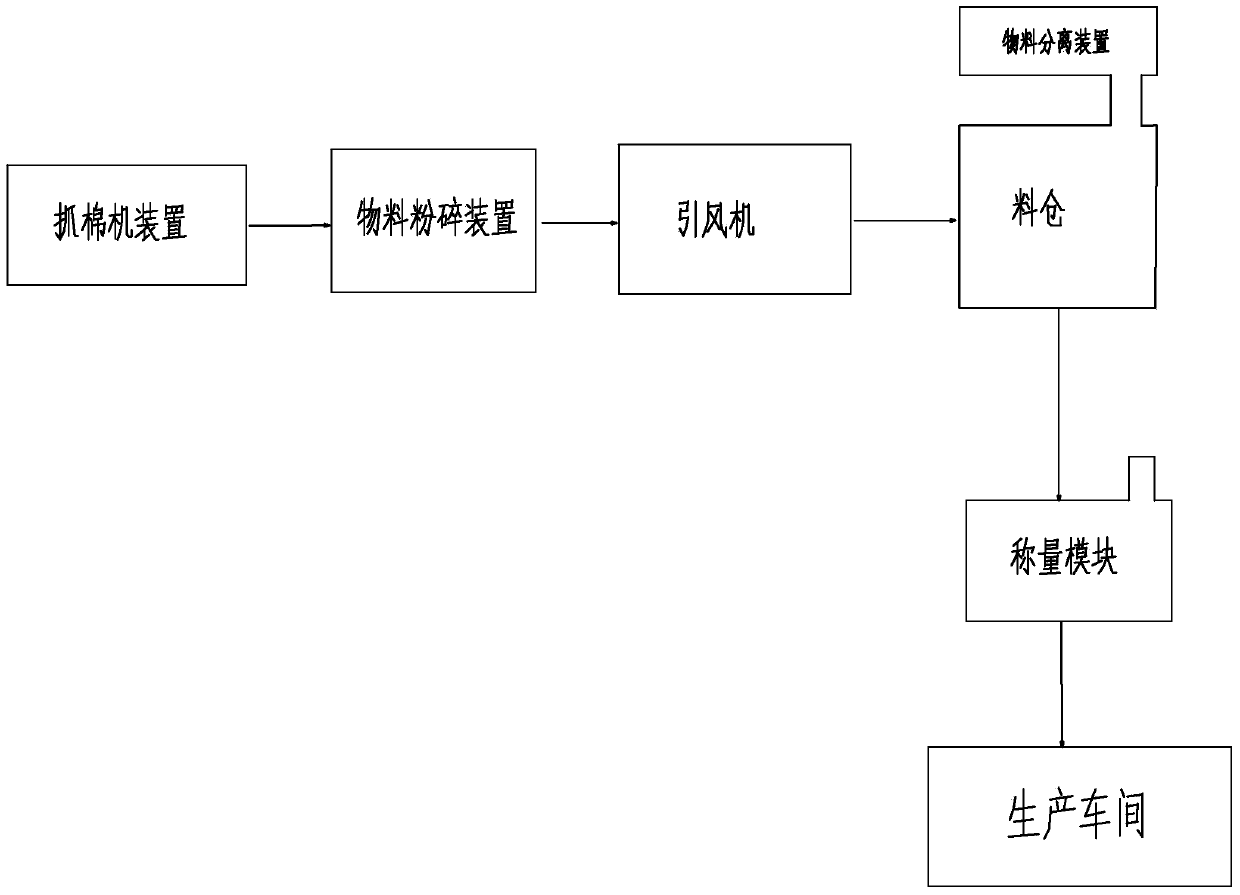

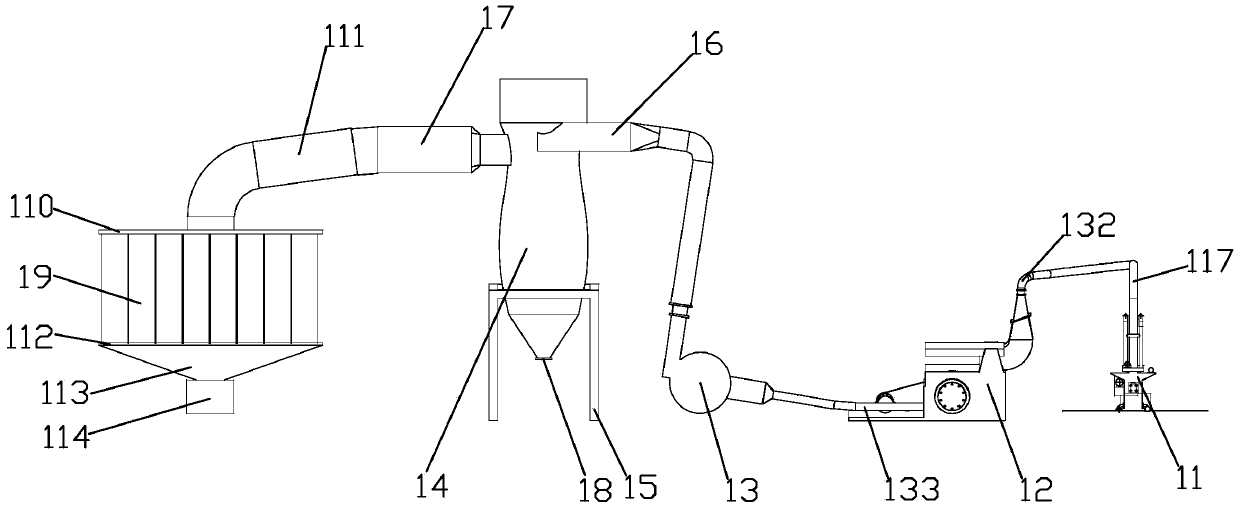

[0036] Such as Figure 1-Figure 10 As shown, the production device of the dust-free hydroxypropyl methylcellulose of the present invention comprises an interconnected cotton grabbing device, a material crushing device, an induced draft fan device, a feed bin, a weighing module and a production workshop, and the feed bin A material separation device is connected to it, and the material separation device includes a secondary sedimentation drying device, the cotton catching machine device, material crushing device, induced draft fan device, silo, weighing module, secondary sedimentation drying device and production workshop are connected by pipes.

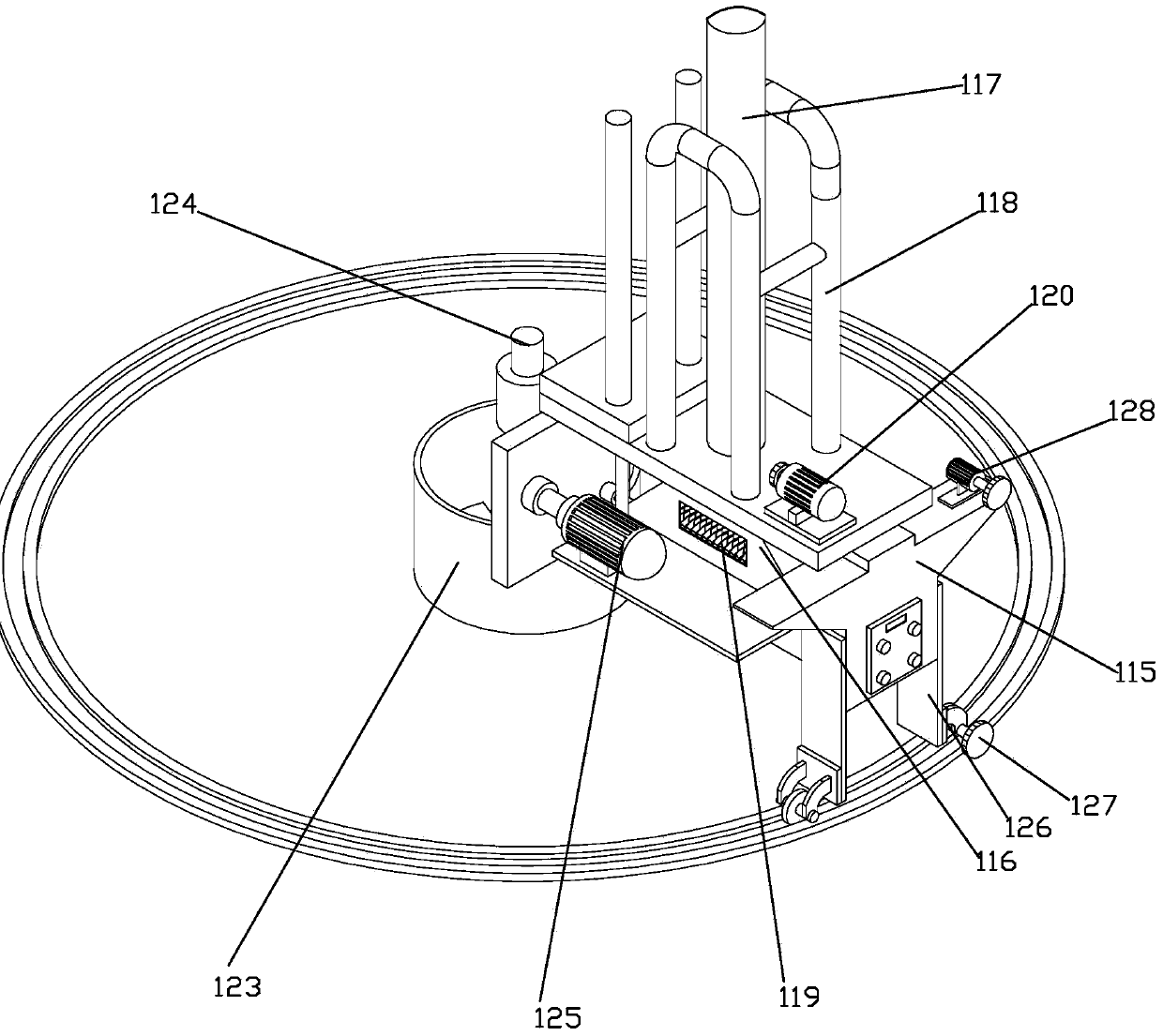

[0037] The cotton bale device in the present invention includes a coarse crushing device 11, a fine crushing device 12, a material storage device and a dust re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com