A straw briquetting production line device

A straw briquetting machine and production line technology, applied in the direction of biofuel, solid fuel, waste fuel, etc., can solve the problems of low degree of automation, reduce storage area, reduce transportation cost, etc., achieve convenient transportation, high combustion efficiency, reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

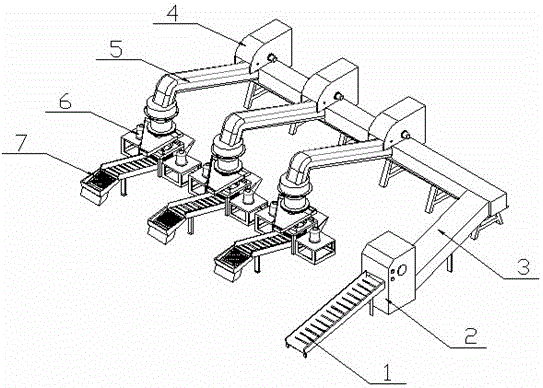

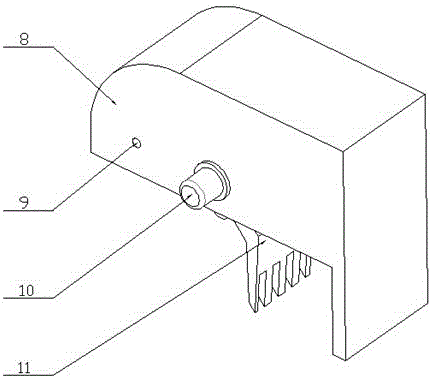

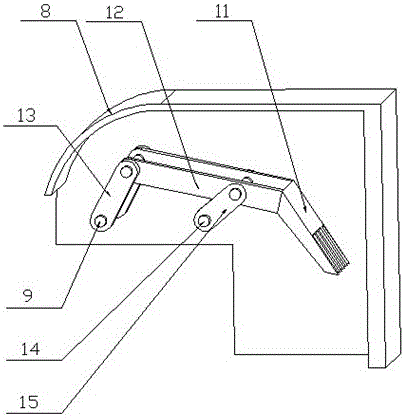

[0023] 1. If Figure 1 to Figure 5 As shown, the present invention provides a straw briquetting production line device, including a feed conveyor 1, a grass cutter 2, a crushed material conveyor 3, a scraper pusher 4, a feeding conveying device 5, and a straw briquetting machine 6. And the discharge conveying device 7; the scraper shifter 4 is composed of a dust cover 8, a pin shaft 9, a frequency conversion motor 10, a scraper 11, a connecting rod 12, a rocker 13, a drive shaft 14, and a crank 15; The blanking dust cover 8 is connected with the feeding hopper through hexagon bolts; the straw briquetting machine is mainly composed of a feeding hopper 18, a compression chamber 19, a ring die 20, a blanking hopper 21, a large motor 23, and a frame 24; A sieve is installed at the outlet of the device 7 .

[0024] 2. The feeding conveyor 1 and the hay cutter 2 can be arranged outdoors. The crushed material conveyor 3, the scraper shifter 4 and the feeding conveying device 5 are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com