Integrated pyrolysis and gasification device for seed coal and integrated pyrolysis and gasification method for seed coal

A technology for pyrolysis gasification and seed coal, applied in the field of coal chemical industry, can solve the problems of low thermal efficiency and cold gas efficiency in the gasification process, difficult recovery and utilization of solid sensible heat, increased investment in air separation plants, etc., so as to improve energy conversion. Efficiency, efficient coupling, effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

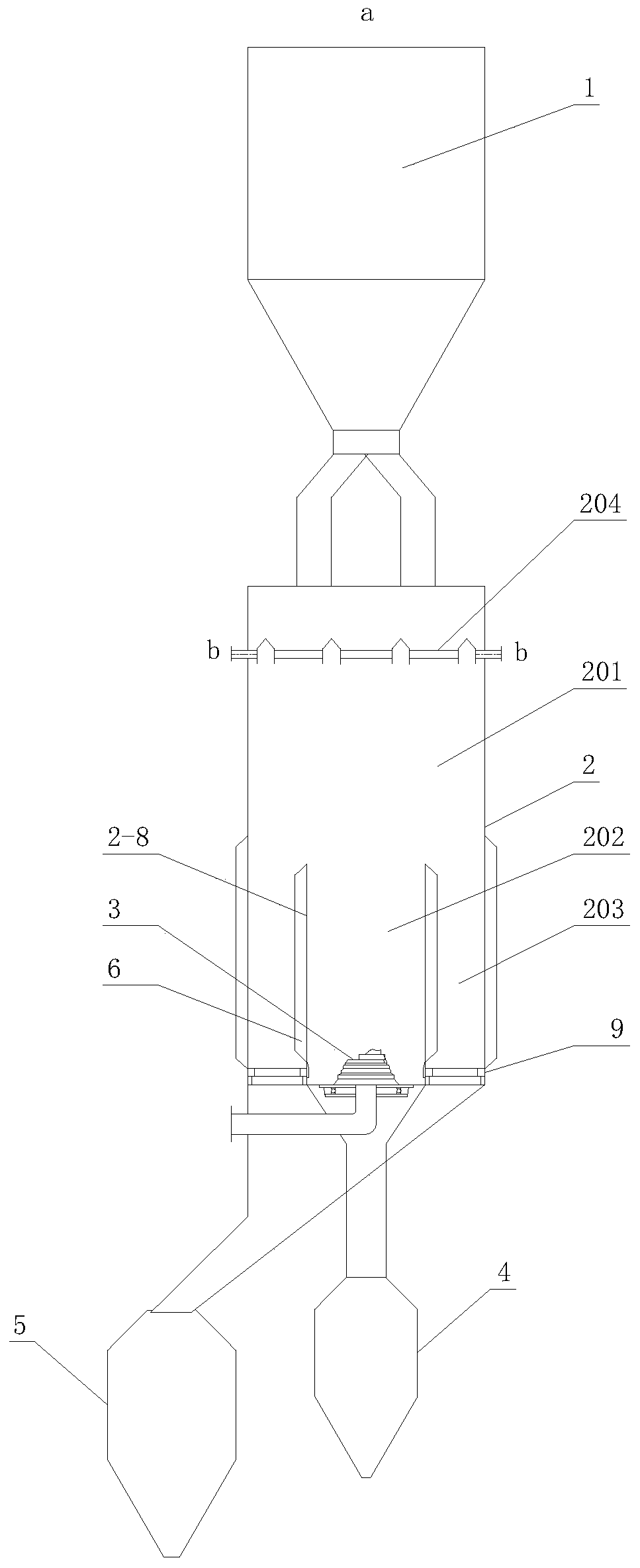

[0045] see figure 1 , the seed coal integrated pyrolysis gasification device in this embodiment includes a raw material bin 1, a reaction bin 2, an ash buffer bin 4, and a semi-coke buffer bin 5; wherein,

[0046]The raw material bin 1 is used for storing and unloading materials; it is fixed on the top of the reaction bin 2, and the top of the raw material bin 1 is provided with a coal inlet, and its bottom is connected with the top coal inlet of the reaction bin 2 through a pipeline.

[0047] The reaction bin 2 is used to pyrolyze and gasify the seed coal in the raw material bin 1. Its shape is a circular cylinder, and its inner cavity is divided into a pyrolysis area 201, a gasification area 202, and a coke discharge area 203. The pyrolysis area 201 Arranged above the gasification zone 202 and the coke discharge zone 203, a raw coal gas outlet is opened on the cylinder wall of the pyrolysis zone 201, and a gas guide 204 is installed above the pyrolysis zone 201, and the gas ...

Embodiment 2

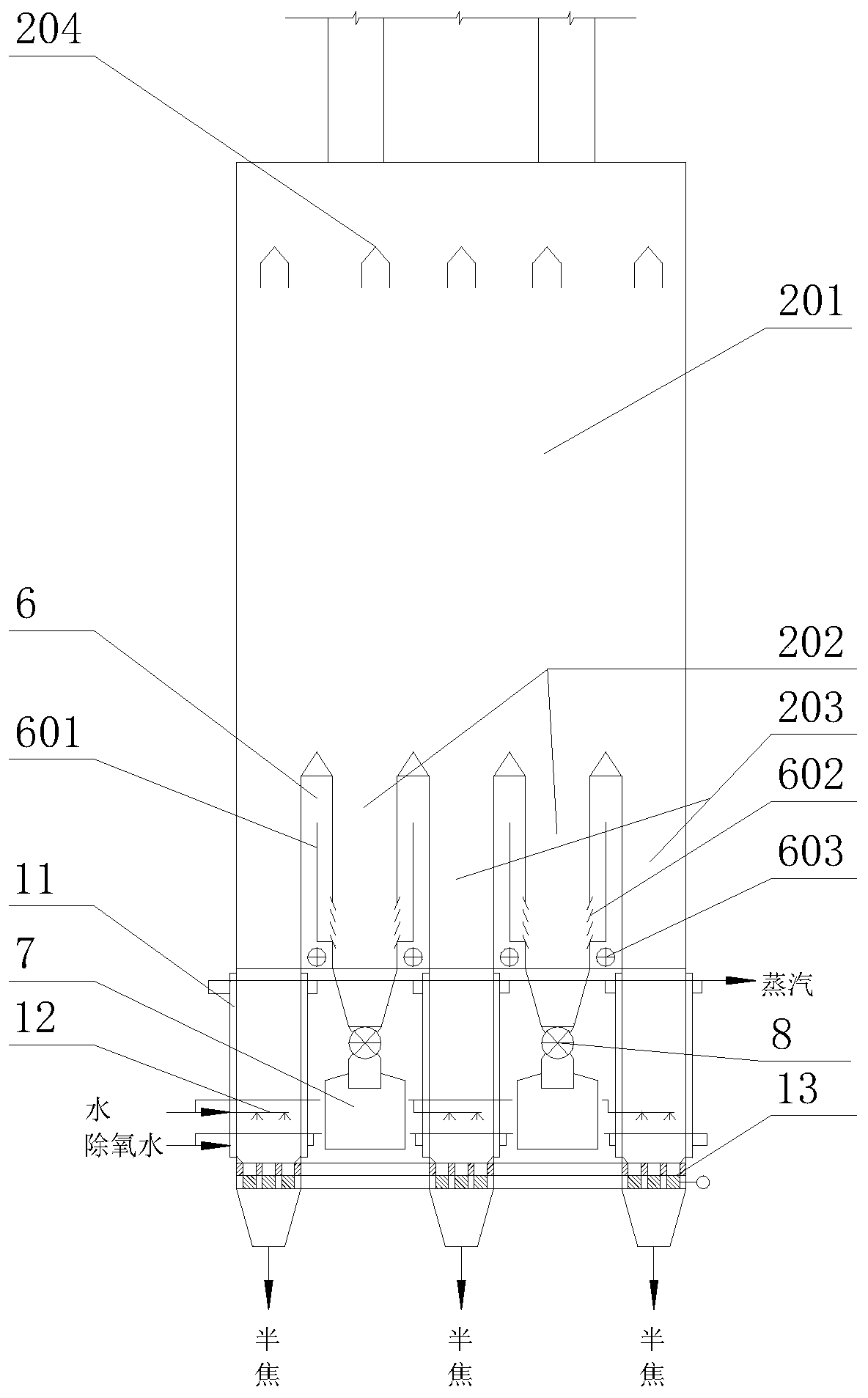

[0054] see figure 2 with 3 , the seed coal integrated pyrolysis gasification device in this embodiment includes a raw material bin 1, a reaction bin 2, an ash buffer bin 4, and a semi-coke buffer bin 5; wherein,

[0055] The raw material bin 1 is used for storing and unloading materials; it is fixed on the top of the reaction bin 2, and the top of the raw material bin 1 is provided with a coal inlet, and its bottom is connected with the top coal inlet of the reaction bin 2 through a pipeline.

[0056] The reaction chamber 2 is used to pyrolyze and gasify the seed coal in the raw material warehouse 1. Its shape is a square cylinder, and its inner cavity is divided into a pyrolysis area 201, a gasification area 202 and a coke discharge area 203. The pyrolysis area 201 is arranged Above the gasification zone 202 and the coke discharge zone 203, a raw coal gas outlet is opened on the cylinder wall of the pyrolysis zone 201, and a gas exporter 204 is installed above the pyrolysis...

Embodiment 3

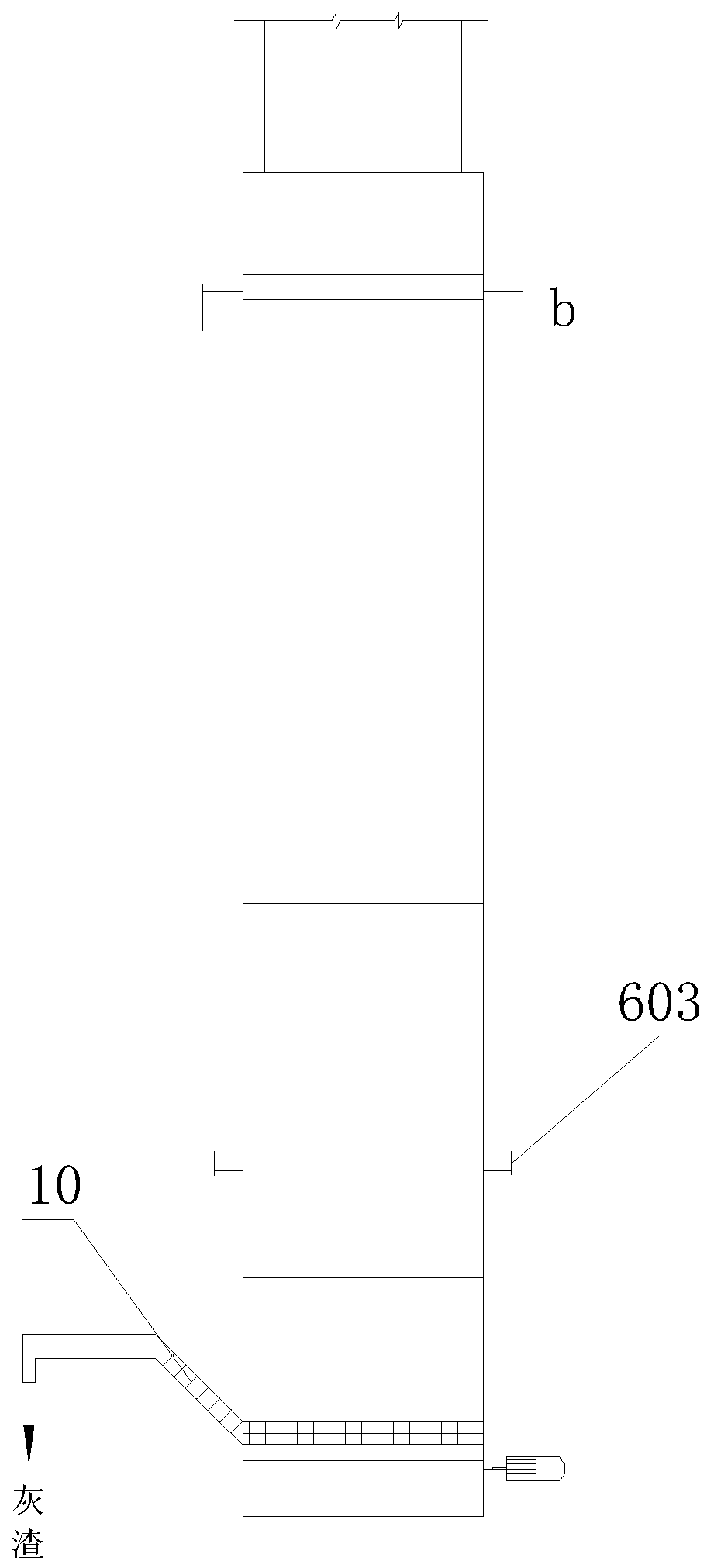

[0067] The difference from Embodiment 1 is that no heat exchange fluid channel 6 is arranged on the outer wall of the coke discharge area 203 in this embodiment, and a heat exchange jacket 11 is arranged on the outer wall of the semi-coke buffer bin 5 below the coke discharge area 203, Deoxygenated water is filled in the heat exchange jacket 11 to further reduce the temperature of the semi-coke and complete the primary cooling of the semi-coke.

[0068] Spraying mechanism 12 and coke pushing mechanism 13 can also be arranged at the bottom of semi-coke buffer storehouse 5, spray water to semi-coke through spraying mechanism 12, realize secondary cooling of semi-coke, can effectively prevent gas from leaking out of coke pushing mechanism 13 at the same time, The coke pushing mechanism 13 further pushes the semi-coke after spray cooling to ensure the smooth discharge of the coke. Further, in order to ensure the effect of gasification and pyrolysis, the semi-coke flux ratio of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com