Polymer mixing system

A polymer and mixing technology, applied in the field of polymer mixing systems, can solve the problems of lack of systematization, low production efficiency of mixed rubber, unsafe, etc., to achieve high production efficiency, wide mixing coverage efficiency, and improved utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

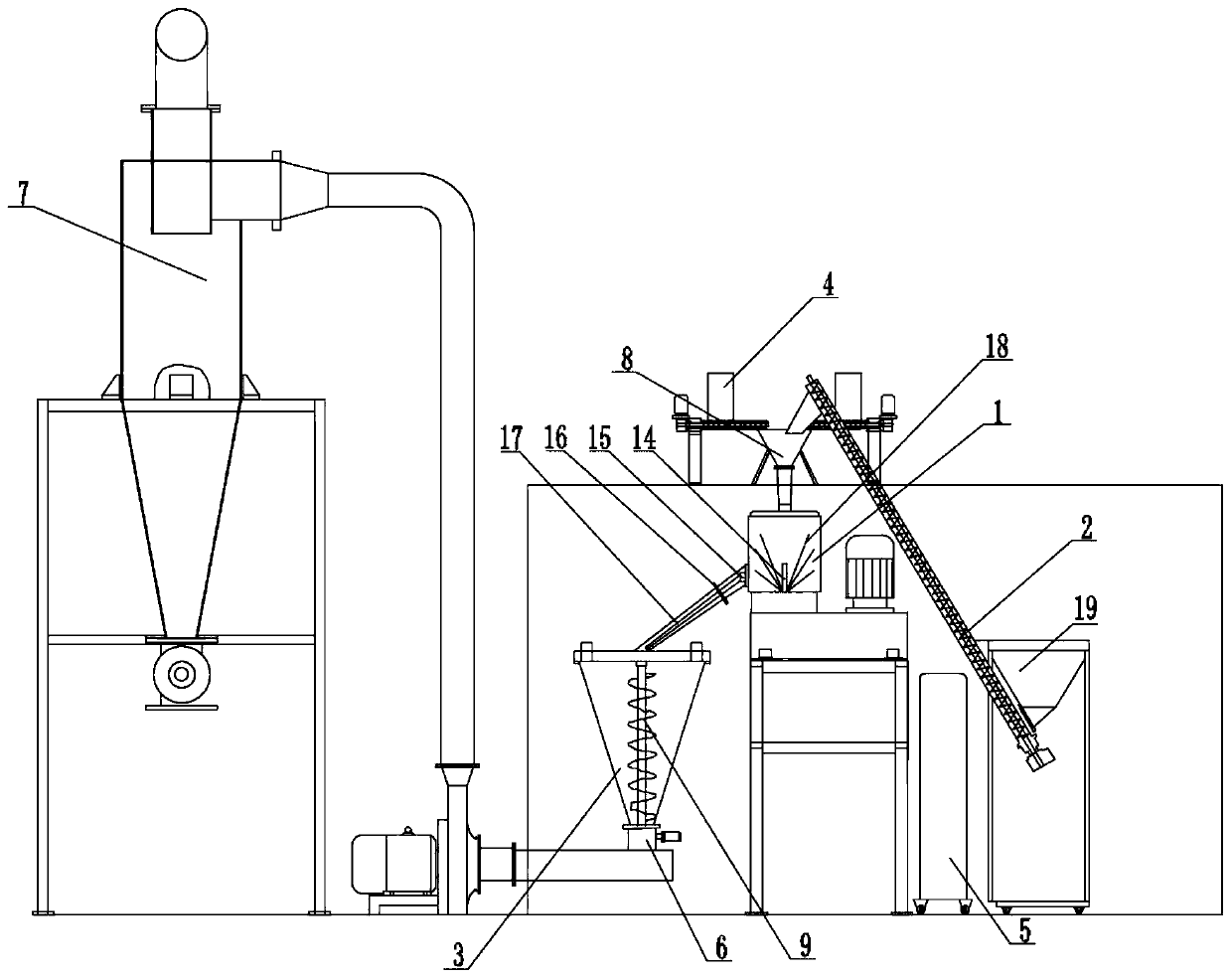

[0038] Such as figure 1 , figure 2 As shown, the polymer mixing system of the present invention includes a polymer kneader 1, a feeder 2 is arranged on one side of the polymer kneader 1, and the outlet of the feeder 2 is connected to the inlet of the polymer kneader 1. The feed port is connected, and one side of the polymer mixer 1 is also provided with a mixing tank 3 and a softener tank 5. The discharge port of the polymer mixer 1 is connected with the feed port of the mixing tank 3 through a feeding device, softening The discharge port of the agent tank 5 is communicated with the feed port of the polymer mixer 1, and the top of the polymer mixer 1 is provided with a screw feeder 4, and the screw feeder 4 is mixed with the polymer through a weighing hopper 8. The refining machine 1 is connected, the bottom of the mixing tank 3 is connected with a discharge pipe 6, and one side of the discharge pipe 6 is connected with a gas conveyor 7, the gas conveyor 7 is located on the ...

Embodiment 2

[0041] Based on embodiment 1, a weighing hopper 8 is arranged above the polymer kneader 1, and the discharge port of the weighing hopper 8 is communicated with the feed port of the polymer kneader 1, and the discharge port of the feeder 2, the screw The discharge ports of the feeder 4 are all communicated with the feed ports of the weighing hopper 8 .

[0042]The invention designs a weighing hopper. The fine rubber powder conveyed by the feeder is weighed through the weighing hopper before entering the polymer mixer. The weighing is convenient, and the amount of fine rubber powder can be accurately measured to ensure that the produced The rubber compound has good performance; the small chemical material conveyed by the screw feeder passes through the weighing hopper and then enters the polymer mixer, which can reasonably control the addition of the small chemical material and facilitate the adjustment of the performance of the rubber compound.

Embodiment 3

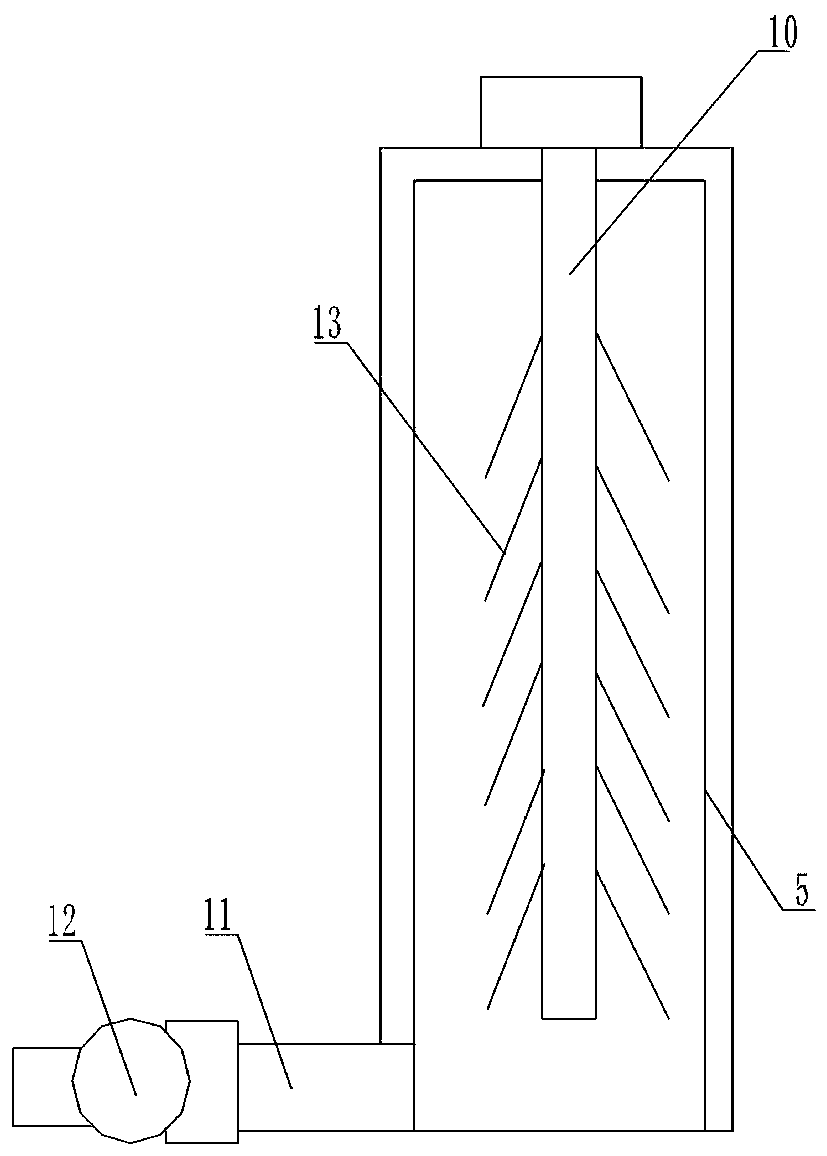

[0044] Based on above-mentioned embodiment, on the tube wall of softening agent tank 5, be covered with light-shielding cloth, the inside of softening agent tank 5 is equipped with vertically placed stirring shaft 10, and the outlet of softening agent tank 5 is connected with the polymer mixer. 1 through the connecting pipe 11 between the feed ports. An electromagnetic metering pump 12 is installed on the connecting pipe 11 . The outer wall of the stirring shaft 10 is provided with multiple short shafts 13 inclined downward.

[0045] The softener needs to be protected from light and heat-insulated. Therefore, the present invention covers the tube wall of the softener tank with a light-shielding cloth, which has the effect of light-shielding and heat-insulating; The softener can be mixed evenly, and the utilization rate of the softener can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com