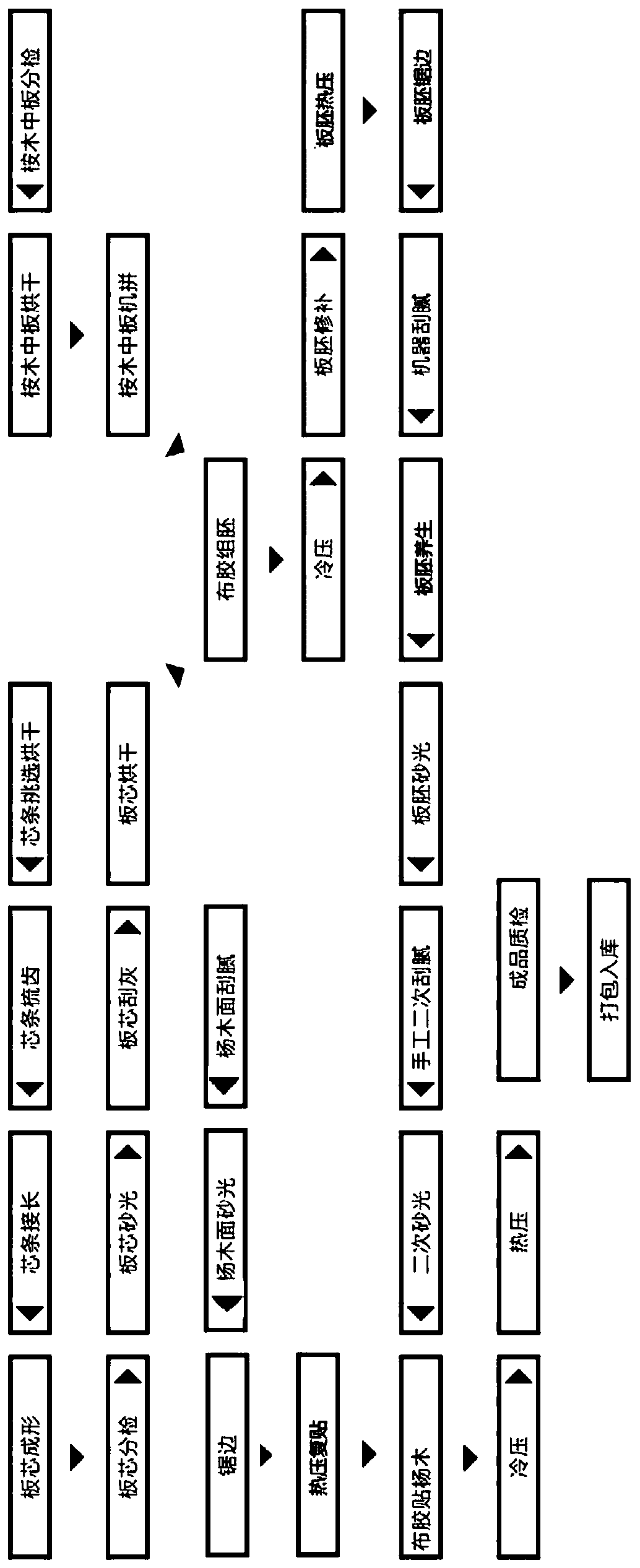

Repasting production process for three-melamine impregnated adhesive film paper veneer fine wood board

A technology of impregnating adhesive film paper and melamine is applied in the direction of wood processing appliances, wood veneer bonding, manufacturing tools, etc., which can solve the problems of poor physical and mechanical properties and appearance quality, low qualified rate of finished products, easy deformation and cracking, etc. Achieve the effect of improving physical and mechanical properties, high qualified rate of finished products, and improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

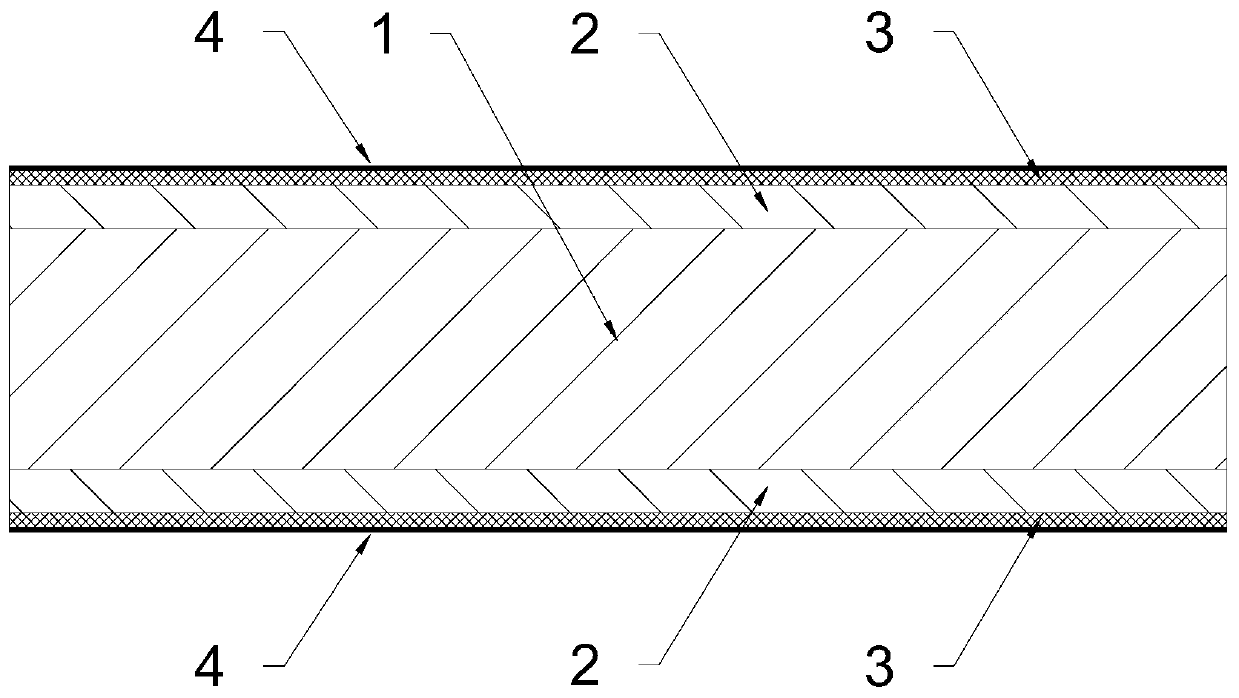

[0045] Such as figure 2 As shown, the invention provides a thin wood board, comprising a board core 1, a eucalyptus middle board 2, a poplar veneer 3, and a melamine-impregnated film paper 4; Above, the eucalyptus middle board 2 and the board core 1 form the blank, the poplar veneer 3 is pasted on the front and back planes of the blank, and the poplar veneer 3 is pasted with melamine-impregnated film paper 4 . In order to reduce the formaldehyde content, the board core 1, the eucalyptus middle board 2, the poplar veneer 3, and the melamine-impregnated film paper 4 were pressed into shape with soybean vegetable glue.

[0046] In order to improve the physical and mechanical properties and appear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com