Bimetallic nickel-cobalt telluride supercapacitor electrode material and preparation method thereof

An electrode material and telluride technology, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of unreported preparation methods of nickel-cobalt bimetallic tellurides, and achieve improved electrochemical performance, fast ionization, etc. / Electron transport, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

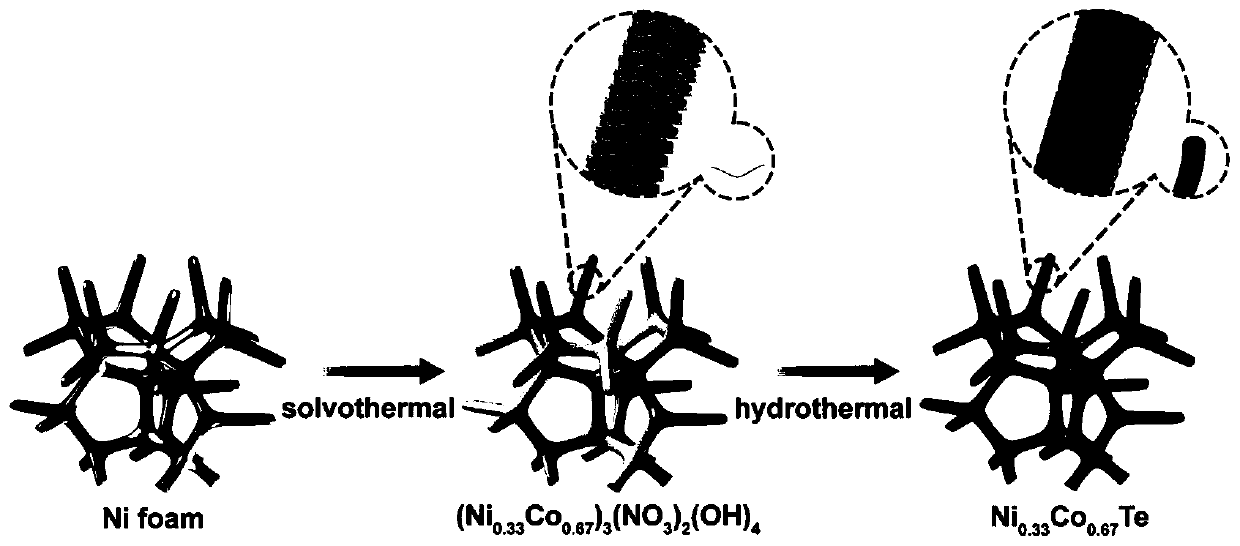

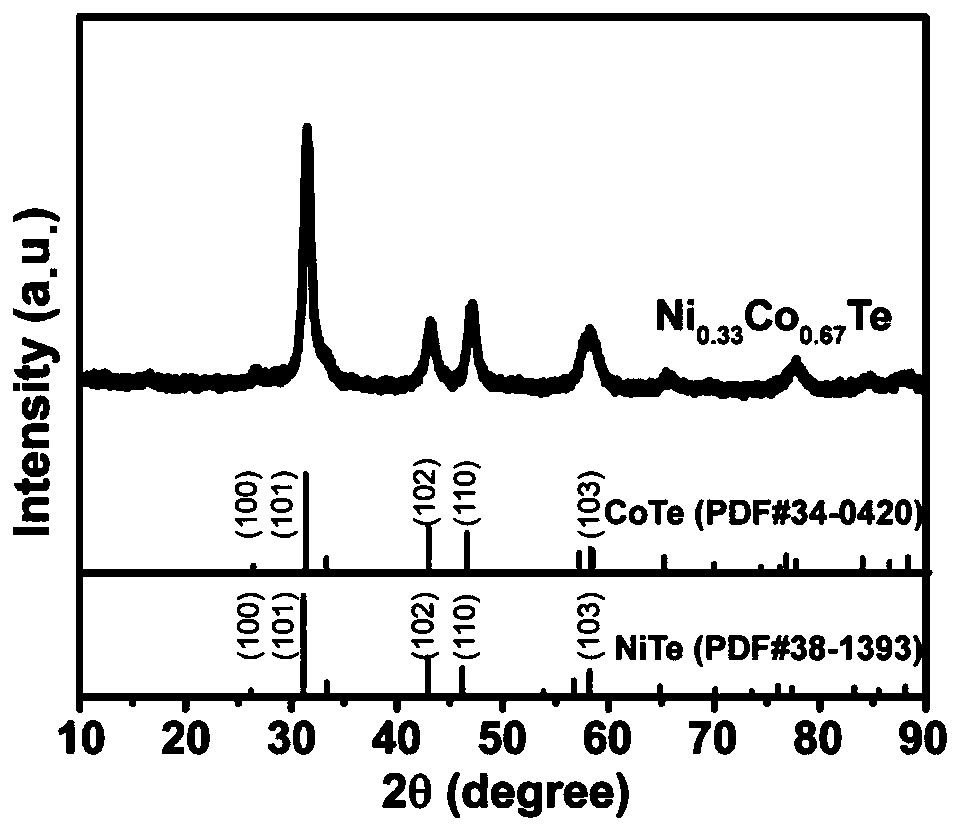

[0029] First, the nickel-cobalt precursor was grown on the nickel foam substrate, and 0.3mmol Ni 2+ and 0.6mmol Co 2+ Dissolve in 60mL ethanol, then add 1.1mmol urea, stir magnetically for 15 minutes to obtain a homogeneous solution. The solution and the cleaned nickel foam were placed in a high-pressure reactor and reacted at 120°C for 8 hours. After cooling to room temperature, the nickel foam was taken out, washed several times with ethanol and deionized water, and dried overnight in an oven at 70°C.

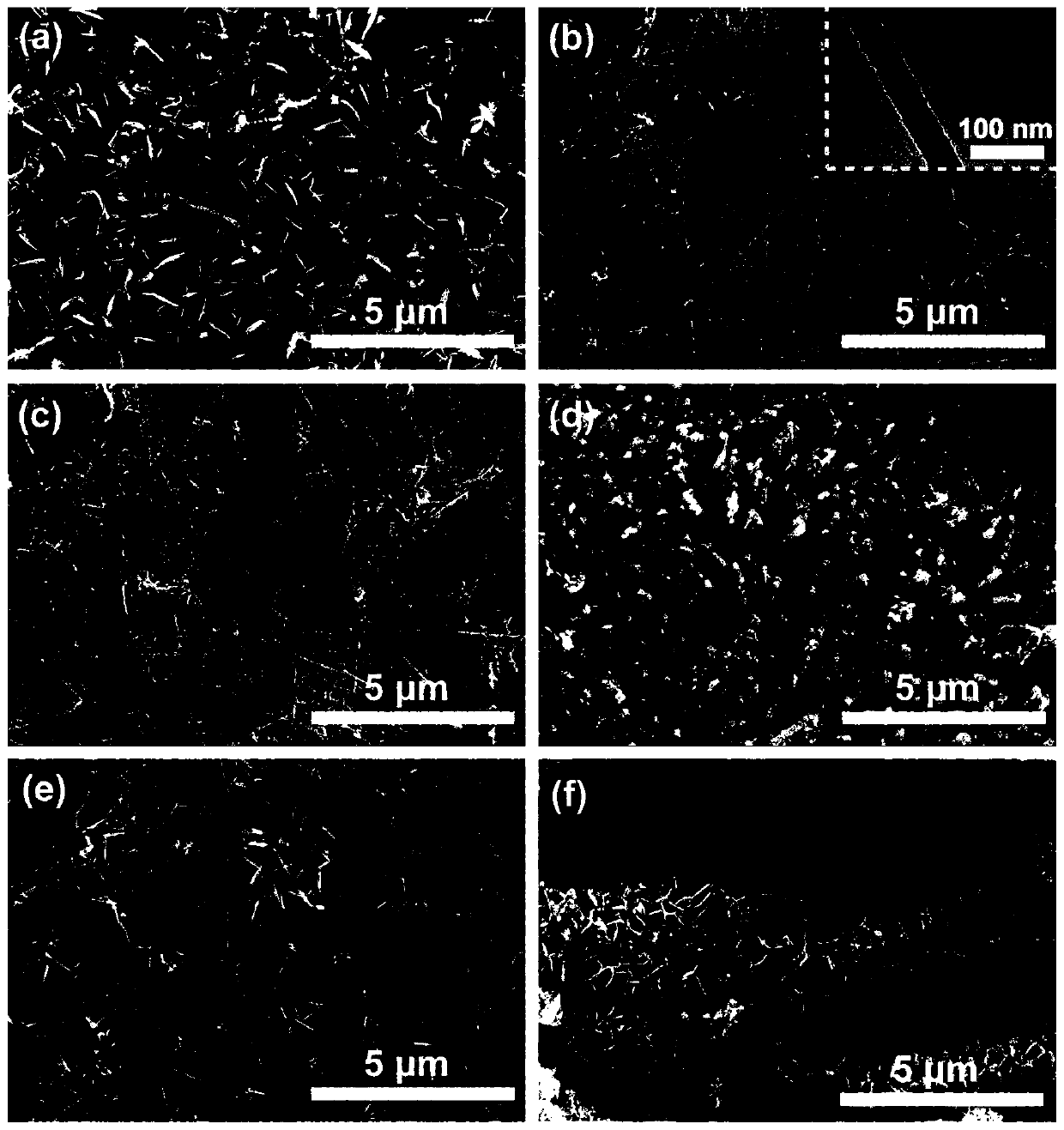

[0030] The second is to prepare nickel cobalt telluride. Prepare 70 ml of 1 mM sodium tellurite aqueous solution, add 5 ml of hydrazine hydrate (80%), and stir magnetically for 30 minutes. The solution was transferred to an autoclave, and nickel foam loaded with nickel-cobalt precursor was put into it at the same time, and the tellurization reaction was carried out at 180° C. for 8 hours. After cooling to room temperature, the nickel foam was taken out, washed several tim...

Embodiment 2

[0032] The implementation process is the same as in Example 1, except that the tellurization reaction time is 12 hours. An electrode material that supports nickel-cobalt-tellurium nanotubes on nickel foam is obtained. See attached figure 2 in b.

Embodiment 3

[0034] The implementation process is the same as in Example 1, except that the tellurization reaction time is 15 hours. An electrode material that supports nickel-cobalt-tellurium nanotubes on nickel foam is obtained. See attached figure 2 in c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com