Flame-retardant self-adhesive waterproof membrane binder, its preparation method and waterproof membrane prepared therefrom

A technology of self-adhesive waterproof membrane and waterproof membrane, which is applied in the field of waterproof membrane, flame-retardant self-adhesive waterproof membrane binder, and can solve a large number of cracks or cracks on the surface of the waterproof layer, affecting the service life of waterproof functional materials, The pellets are easy to fall off and other problems, so as to achieve the effects of good waterproof performance, good anti-aging performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A flame-retardant modified asphalt waterproof coil excellent in anti-aging properties, including upper and lower protective films, a flame retardant self-adhesive waterproof coil measuring layer, a tire The base layer, a lower self-adhesive waterproof gel layer and a lower protective film composed of flame retardant self-adhesive waterproof coil.

[0031] The preparation method of the adhesive waterproof tester and the lower adhesive water supply tester is as follows:

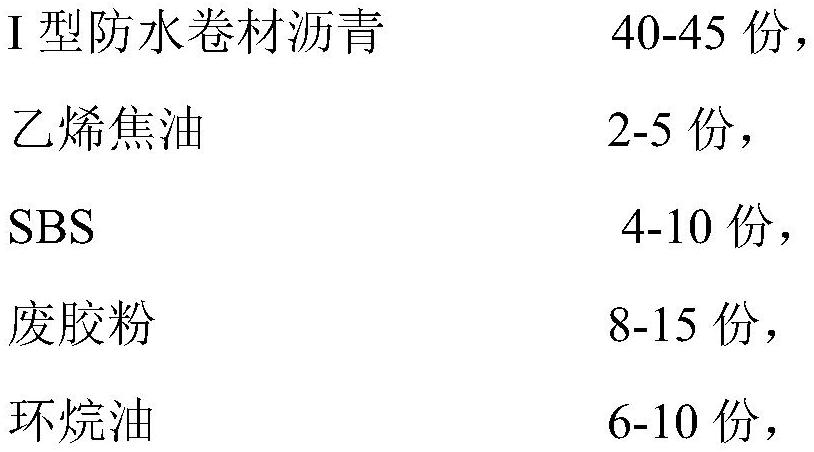

[0032] First, 40 I-type waterproof web asphalt and 2 parts of ethylene tar were first heated to 195 ± 5 ° C, and 6 servantic oils and 4 parts of chlorinated paraffin were added evenly to 185 ± 5 ° C, and 4 parts of SBS synthetic rubber were added. The temperature rose to 195 ± 5 ° C, control temperature, stirred 1.5 h, then add 3 tackifiable resins (15 parts of the ancient Malon resin, 15 seroponal resins, 15 parts of carbon nine resin) and 8 waste plastic powder continue It was stirred at this temperature f...

Embodiment 2

[0035] A flame-retardant modified asphalt waterproof coil excellent in anti-aging properties, including upper and lower protective films, a flame retardant self-adhesive waterproof coil measuring layer, a tire The base layer, a lower self-adhesive waterproof gel layer and a lower protective film composed of flame retardant self-adhesive waterproof coil.

[0036] The preparation method of the adhesive waterproof tester and the lower adhesive water supply tester is as follows:

[0037] First, 40 I-type waterproof web asphalt and 2 parts of ethylene tar were first heated to 195 ± 5 ° C, and 10 servant oils and 8 parts of chlorinated paraffin were mixed to 185 ± 5 ° C, and 8 parts of SBS synthetic rubber were added. The temperature rose to 195 ± 5 ° C, control temperature, stirred 1.5 h, then add 9 tackifier resins (15 parts of the ancient Malon resin, 15 seropon resin, 15 parts of carbon nine resin) and 8 waste plastic powder continue At this temperature at a temperature of 0.5 h, 15...

Embodiment 3

[0040] A flame-retardant modified asphalt waterproof coil excellent in anti-aging properties, including upper and lower protective films, a flame retardant self-adhesive waterproof coil measuring layer, a tire The base layer, a lower self-adhesive waterproof gel layer and a lower protective film composed of flame retardant self-adhesive waterproof coil.

[0041] The preparation method of the above-stick waterproof tester and the adhesive water purification tester are as follows: 1 first Type I waterproof coil asphalt and 3 parts of ethylene tar temperature to 195 ± 5 ° C, 8 cycloalkyl oil and 7 parts The fossile wax is stirred evenly to 185 ± 5 ° C, then 8 parts of SBS synthetic rubber temperature rise to 195 ± 5 ° C, control temperature, stirred 1.5 h, then add 7 parts of the tackifying resin (15 parts of the ancient Moron resin, terpene 15 parts of the resin, 15 parts of carbon nine resin) and 11 waste plastic powder continued to stir at this temperature for 0.5 h, and then 15 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com