Asphalt polyurethane waterproof coating suitable for cement base layer and preparation method and application of asphalt polyurethane waterproof coating

A polyurethane waterproof and polyurethane prepolymer technology, applied in polyurea/polyurethane coatings, asphalt coatings, coatings, etc., can solve problems such as unfavorable safe production, unsuitable for industrial production, uncontrollable reaction process, etc., and achieve fast surface drying Hard drying time, beneficial to on-site construction, moderate viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example provides a bituminous polyurethane waterproof coating suitable for cement bases. In terms of parts by mass, its raw materials include: 30 parts of end-blocked polyurethane prepolymers, 60 parts of road No. 10 bitumen, 1 part of polyethylene wax, water-removing Agent silane 171 1 part, dibutyltin dilaurate 0.1 part, fumed silica 0.5 part, vinyltriethoxysilane 0.2 part, calcium oxide 0.1 part.

[0043] The preparation method comprises the following steps:

[0044] (1) Preparation of end-capped polyurethane prepolymer:

[0045] 50 parts of Dongda polyether diol 2000 were vacuum dehydrated at 120°C and -0.1MPA to a moisture content below 0.05%, and then mixed with 10 parts of BASF TDI and reacted at 80°C for 3 hours. The measured NCO content was about Terminate reaction when 4.6%, make 60 parts of polyurethane prepolymers;

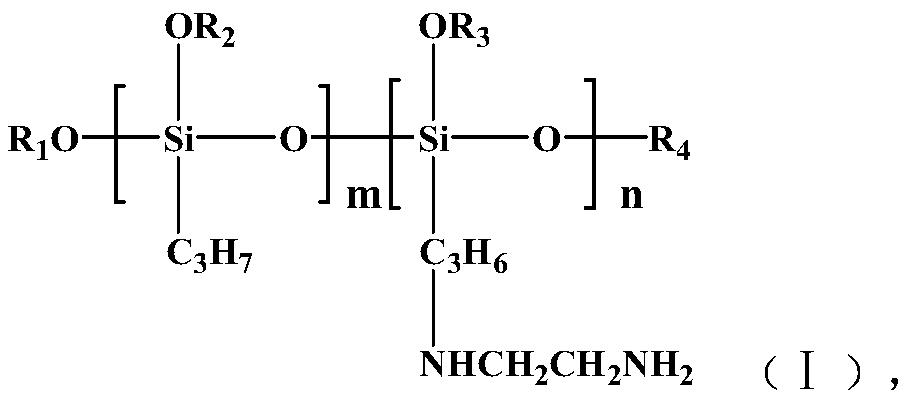

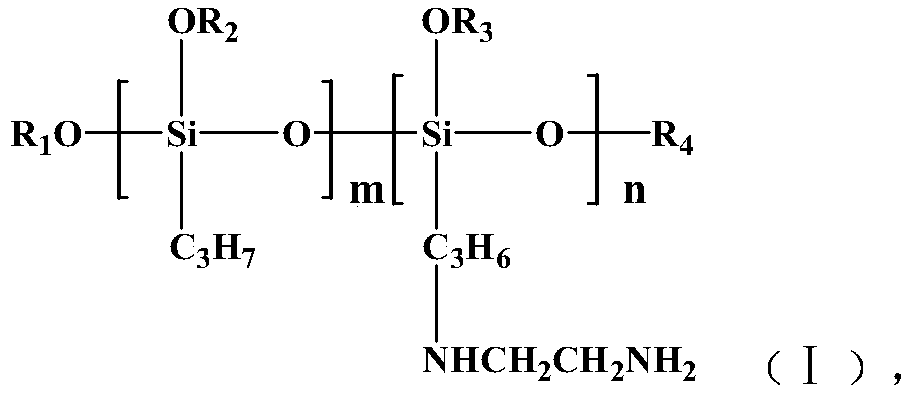

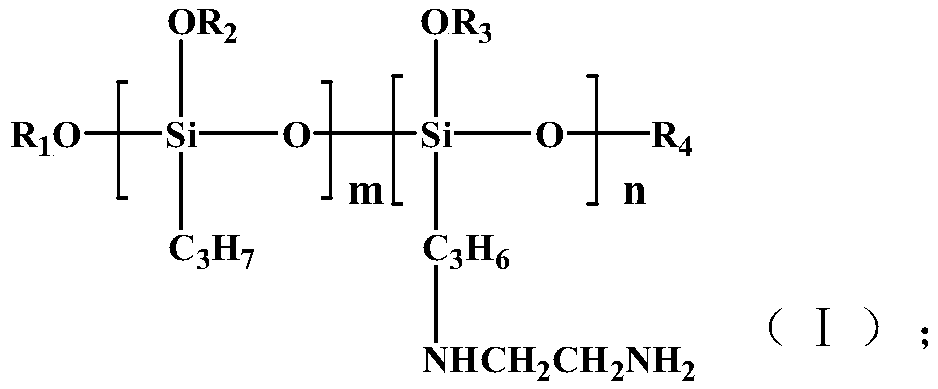

[0046] Then 20 parts of the compound shown in formula (I-1) was mixed with 60 parts of the polyurethane prepolymer prepared by the above...

Embodiment 2

[0049] This example provides a bituminous polyurethane waterproof coating suitable for cement bases. In terms of parts by mass, its raw materials include: 40 parts of end-blocked polyurethane prepolymer, 55 parts of road No. 10 bitumen, 1 part of polyethylene wax, water-removing 1 part of agent silane 171, 0.2 part of dibutyltin dilaurate, 0.7 part of fumed silica, 0.1 part of vinyltriethoxysilane, and 0.1 part of calcium oxide.

[0050] The preparation method comprises the following steps:

[0051] (1) Preparation of end-capped polyurethane prepolymer:

[0052] 50 parts of Dongda Polyether Diol 2000 and 25 parts of Dongda Polyether Diol 1000 were vacuum dehydrated at 120°C and -0.1MPA to a moisture content below 0.05%, and then mixed with 20 parts of BASF TDI in React at 80°C for 3 hours, stop the reaction when the measured NCO content is about 5.8%, and make 95 parts of polyurethane prepolymer;

[0053] Then 50 parts of the compound shown in formula (I-2) was mixed with 95...

Embodiment 3

[0056] This example provides a bituminous polyurethane waterproof coating suitable for cement bases. In terms of parts by mass, its raw materials include: 50 parts of end-blocked polyurethane prepolymer, 40 parts of road No. 10 bitumen, 1 part of polyethylene wax, water-removing Agent silane 171 1 part, dibutyltin dilaurate 0.1 part, fumed silica 0.8 part, vinyltriethoxysilane 0.2 part, calcium oxide 0.2 part.

[0057] The preparation method comprises the following steps:

[0058] (1) Preparation of end-capped polyurethane prepolymer:

[0059] 25 parts of Dongda Polyether Diol 400 and 25 parts of Dongda Polyether Diol 1000 were vacuum dehydrated at 120°C and -0.1MPA to a moisture content below 0.05%, and then mixed with 45 parts of BASF MDI in React at 80°C for 2 hours, stop the reaction when the measured NCO content is about 8.17%, and make 95 parts of polyurethane prepolymer;

[0060] Then 55 parts of the compound shown in formula (I-3) were mixed with 95 parts of the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com