High hardness wear-resistant fingerprint-proof nano coating for PC material and preparation method of high hardness wear-resistant fingerprint-proof nano coating

A nano-coating, anti-fingerprint technology, used in coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems of non-wear resistance, low hardness, poor anti-fouling performance, etc. The effect of high hardness, oil and impact resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The specific raw material formula of the coating is: 30 parts of main resin (15 parts of 6-functional urethane acrylate, 12 parts of 9-functional aromatic urethane acrylate, 3 parts of 15-functional aliphatic urethane acrylate), 8 parts of 6-functional dipentaerythritol hexaacrylate , 3 parts of low-official monomer (2-official, three-official mass ratio is 2:1), 2.5 parts of fluorinated acrylic monomer, 0.7 part of nano-diamond particles, 0.1 part of leveling agent, 0.1 part of light stabilizer, fluorine-containing function 1.5 parts of auxiliary agent, 1 part of photoinitiator (1:1 combination of triethanolamine and triisopropanolamine), and 1:1 composition of butyl acetate and isopropanol as solvent.

[0028] Among them, the hexafunctional urethane acrylate is a hexafunctional urethane acrylate oligomer INV-UV601, provided by Guangzhou Haoyi Technology Co., Ltd.;

[0029] 9-functional aromatic urethane acrylate is ZC6401, provided by Shenzhen Zicai Chemical Co., Ltd....

Embodiment 2

[0042] The difference from Example 1 is that in the composition of raw materials, 10 parts of 6-functional urethane acrylate, 9 parts of 9-functional aromatic urethane acrylate, 4 parts of 15-functional aliphatic urethane acrylate, 0.5 parts of nano-diamond particles, fluorosilane Be 0.75 part, other is identical with embodiment 1.

Embodiment 3

[0044] The difference from Example 1 is that the raw material formula consists of 13 parts of 6-functional urethane acrylate, 10 parts of 9-functional aromatic urethane acrylate, 2 parts of 15-functional aliphatic urethane acrylate, 2 parts of metafluorinated acrylic monomer, fluorosilane 1.25 parts; Others are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

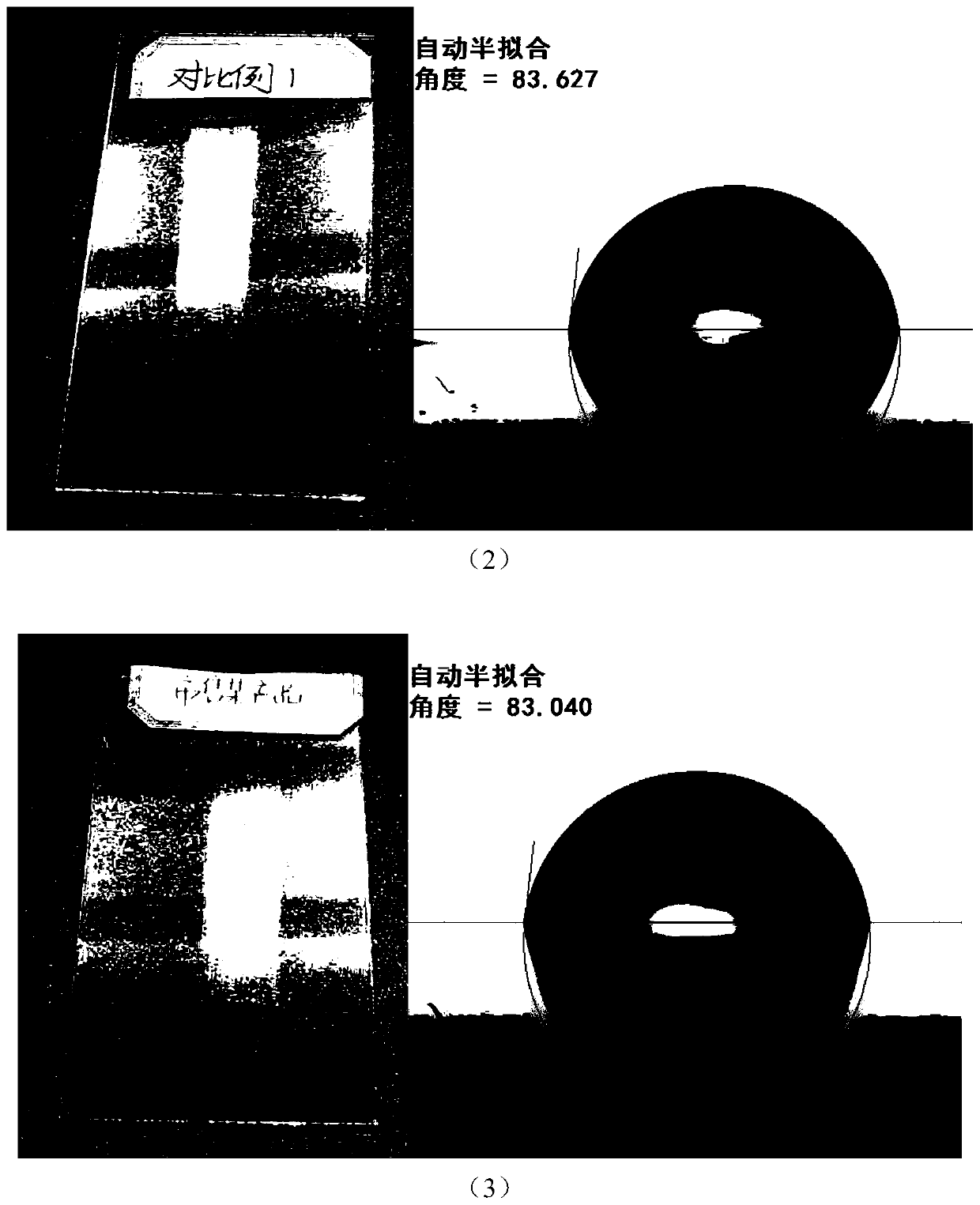

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com