Outer coating cable material for high-frequency and high-speed communication cables and preparation method of cable material

A high-speed communication and outer cladding technology, applied in sustainable manufacturing/processing, plastic/resin/wax insulators, organic insulators, etc. Possibly, solve the problem of attenuation of transmission signal strength, solve the effect of reducing electromagnetic wave coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The outer coating cable material for high-frequency and high-speed communication cables includes the following raw materials in parts by mass:

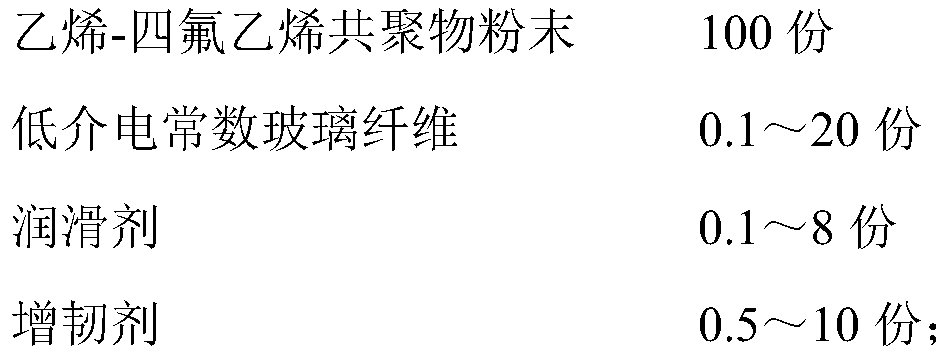

[0047] A component:

[0048]

[0049] B component:

[0050]

[0051] C component:

[0052] 0.3 parts of 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5-triazin-2-yl)-5-octyloxyphenol;

[0053]The dielectric constant of the low dielectric constant glass fiber is 7C 2 / (N·M 2 ), the glass fiber length is 24mm.

[0054] The molecular weight of described ethylene-tetrafluoroethylene copolymer powder is 1.5 * 10 5 , the particle size is 72 μm.

[0055] The preparation method is:

[0056] In terms of parts by mass, 100 parts of ethylene-tetrafluoroethylene copolymer powder (ETFE), 2 parts of low dielectric constant glass fiber, 0.5 part of polytetrafluoroethylene micropowder, and 0.5 part of polyolefin elastomer are added to the double planetary stirring force Mixer, set the temperature at 90°C, mix and stir for 1 hour to obtain m...

Embodiment 2

[0058] The outer coating cable material for high-frequency and high-speed communication cables includes the following raw materials in parts by mass:

[0059] A component:

[0060]

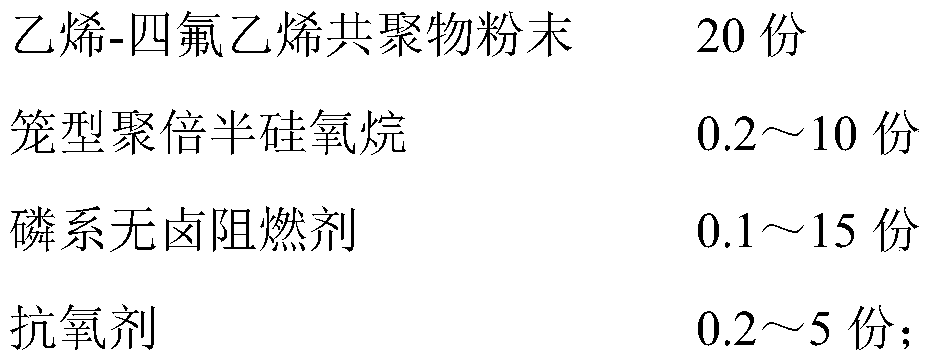

[0061] B component:

[0062]

[0063] C component:

[0064] 1 part of 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5-triazin-2-yl)-5-octyloxyphenol;

[0065] The dielectric constant of the low dielectric constant glass fiber is 5.5C 2 / (N·M 2 ), the glass fiber length is 19mm.

[0066] The molecular weight of described ethylene-tetrafluoroethylene copolymer powder is 1.6 * 10 5 , the particle size is 81 μm.

[0067] The preparation method is:

[0068] In parts by mass, 100 parts of ethylene-tetrafluoroethylene copolymer powder, 5 parts of low dielectric constant glass fiber, 3 parts of polyethylene wax, and 3 parts of hydrogenated styrene-butadiene block copolymer (SEBS) were added Go to the double planetary stirring mixer, set the temperature at 100°C, mix and stir for 1 hour to obtain materi...

Embodiment 3

[0070] The outer coating cable material for high-frequency and high-speed communication cables includes the following raw materials in parts by mass:

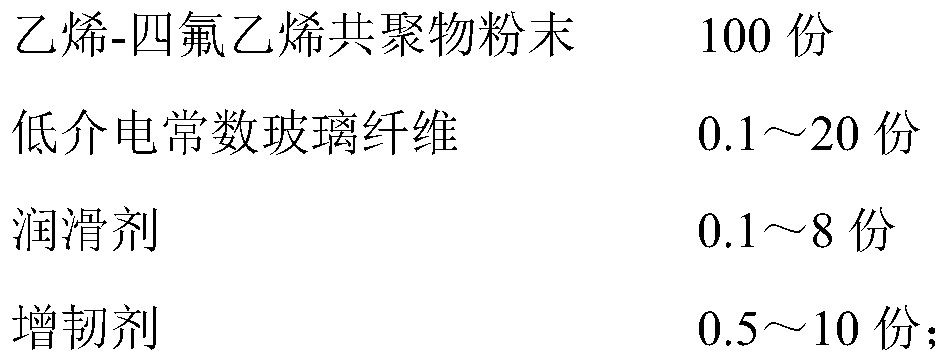

[0071] A component:

[0072]

[0073] B component:

[0074]

[0075] C component:

[0076] 2 parts of 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5-triazin-2-yl)-5-octyloxyphenol;

[0077] The dielectric constant of the low dielectric constant glass fiber is 4.8C 2 / (N·M 2 ), the glass fiber length is 18mm.

[0078] The molecular weight of described ethylene-tetrafluoroethylene copolymer powder is 1.6 * 10 5 , the particle size is 72 μm.

[0079] The preparation method is:

[0080] In parts by mass, 100 parts of ethylene-tetrafluoroethylene copolymer powder, 10 parts of low dielectric constant glass fiber, 2 parts of polyethylene wax and 3 parts of polytetrafluoroethylene micropowder mixture, 5 parts of hydrogenated styrene-butane The olefinic block copolymer (SEBS) is added to a double planetary stirring mixer, set the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com