Aluminum strip for cigarette package ink and preparation method of aluminum strip

A technology of ink and cigarette packs, which is applied in the field of metal pigments and inks, can solve the problems of not being able to obtain aluminum strip products, achieve excellent hiding power, excellent application prospects, and reduce VOCs and dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

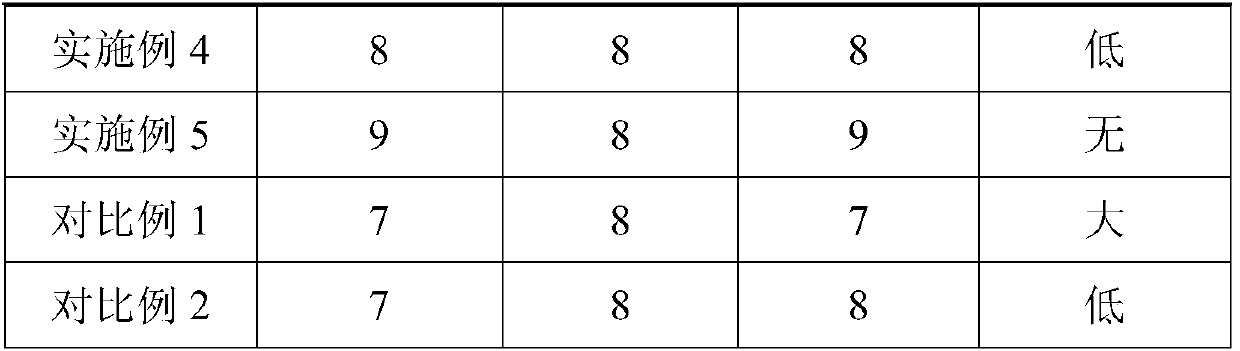

Examples

preparation example Construction

[0023] The preparation process of aluminum strips for cigarette pack ink is as follows:

[0024] 1) Mix the raw materials in the following mass percentages evenly: 30% to 80% of solvent, 0.1% to 3% of initiator, 10 to 50% of aluminum paste, 5 to 30% of A component and 1 to 10% of B component. The A component is used to provide free acrylic acid and / or acrylate, and the B component is used to provide cellulose functional molecules;

[0025] 2) First raise the temperature to 15°C, let the mixed material react for 8 hours, then raise the temperature to 40°C, let the mixed material continue to react for 3 hours, part of the free acrylic acid and / or acrylate in the solution cooperates with the cellulose functional molecules to carry out the reaction on the surface of the aluminum sheet Functional modification, the remaining acrylic acid and / or acrylate undergoes free radical polymerization on the surface of the aluminum sheet, and the polymer formed after free radical polymerizatio...

Embodiment 1

[0029] The process of preparing ink aluminum strips in this embodiment is as above, specifically, the raw materials include 40% of n-propyl acetate, 1% of benzoyl peroxide, 29% of aluminum paste, 2% of cellulose acetate butyrate, 8% of methacrylic acid %, butyl acrylate 10%, hydroxypropyl methacrylate 10%.

Embodiment 2

[0031] The process of preparing ink aluminum strips in this embodiment is as above, specifically, the raw materials include 60% of n-propyl acetate, 3% of dibenzoyl peroxide, 30% of aluminum paste, 2% of cellulose acetate propionate, methacrylic acid 1%, butyl acrylate 2%, hydroxypropyl methacrylate 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com