Device and method for improving removal efficiency of round billet cutting edge

A technology for cutting nodules and round billets, which is applied in the field of devices that improve the efficiency of cutting nodules and round billets, and can solve problems such as low efficiency, long time required, and difficulty in manually cleaning and cutting nodules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

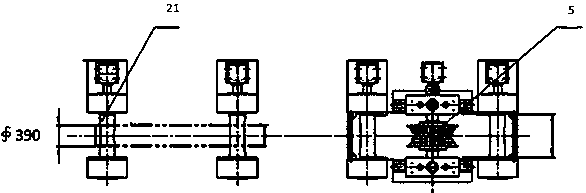

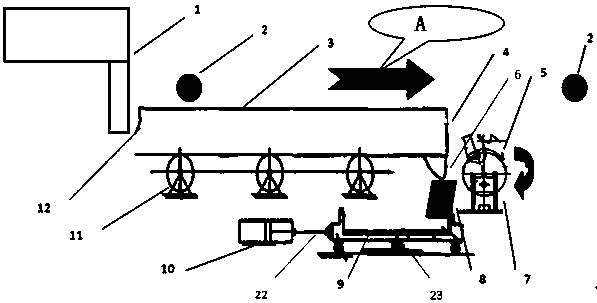

[0131] Such as Figure 1~6 As shown in the figure, a device for improving the removal efficiency of round billets, including a billet cutting surface detection device, a scraper device for cutting tumors, a cutting tumor collecting device, and a cutting tumor pushing device,

[0132] The slab cutting surface detection device includes a grating detection device, which is composed of a signal transmitter and a signal receiver;

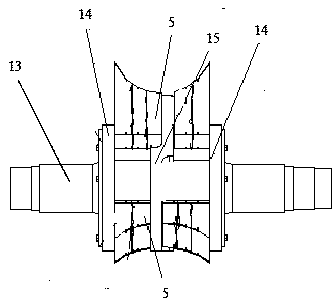

[0133] The scraper device for cutting tumor includes a scraper connecting part and a transmission device, and the scraper connecting part is the core component of the scraper device for cutting tumor, including a scraper group, a main shaft 13, a pin shaft and a flange; the scraper group consists of five scrapers 5 arranged side by side in the axial direction Together as a group, two second flanges 15 are welded to the middle shaft section of the main shaft, and two first flanges 14 are welded to the end of the main shaft; four sets of long pin shafts 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com