Method for preparing ITO/porous carbon composite wave-absorbing material by taking In-MOFs as template

A composite wave absorbing material, porous carbon technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of complex preparation methods, high equipment requirements, and high costs, and achieve simple follow-up processing, high equipment requirements, and high costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

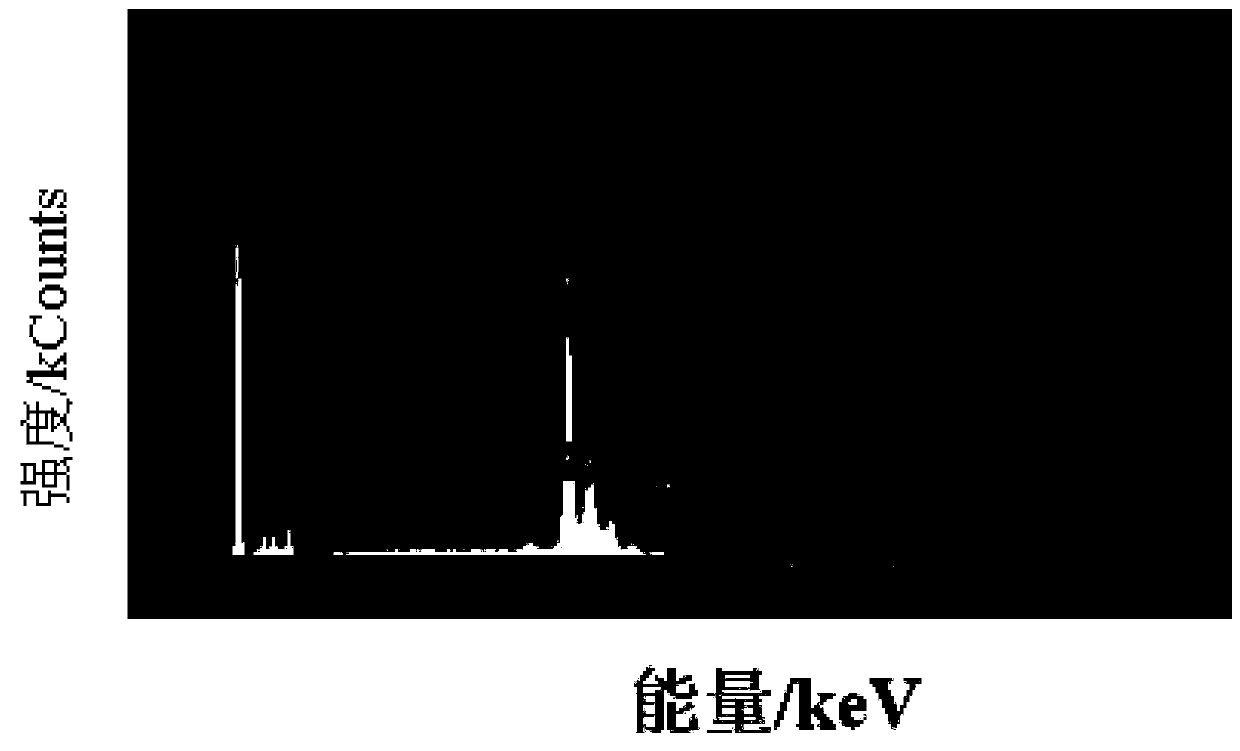

Image

Examples

specific Embodiment approach 1

[0026] Specific implementation mode 1: This implementation mode is a method for preparing ITO / porous carbon composite wave-absorbing materials using In-MOFs as a template, specifically according to the following steps:

[0027] 1. Dissolve indium trichloride tetrahydrate, tin tetrachloride pentahydrate, terephthalic acid and triethylamine in deionized water together, then transfer to an autoclave, and keep warm at 150℃~160℃ for 18h~20h , the obtained product was washed with deionized water and absolute ethanol alternately and centrifuged three times; finally placed in a vacuum oven and dried at 80°C to 85°C under vacuum conditions to obtain In 2-x sn x (OH) 3 (BDC) 1.5 white crystals;

[0028] The molar ratio of the indium element in the described indium trichloride tetrahydrate to the tin element in the tin tetrachloride pentahydrate is (4~12):1;

[0029] The mol ratio of described terephthalic acid and triethylamine is (1~1.1):1;

[0030] The mol ratio of described tin ...

specific Embodiment approach 2

[0033]Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mol ratio of the indium element in the tetrahydrate indium trichloride described in the step 1 and the tin element in the pentahydrate tin tetrachloride is 12: 1. Others are the same as the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the molar ratio of the indium element in the tetrahydrate indium trichloride described in step one to the tin element in the pentahydrate tin tetrachloride is 9:1. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com